Large floor-standing fluidized storage

A floor-standing and fluidized technology, applied in large-scale containers, containers, packaging, etc., can solve the problems of difficult inspection, economic losses, casualties, etc., and achieve the effect of less difficulty in feeding materials, less supporting facilities, and reduced maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

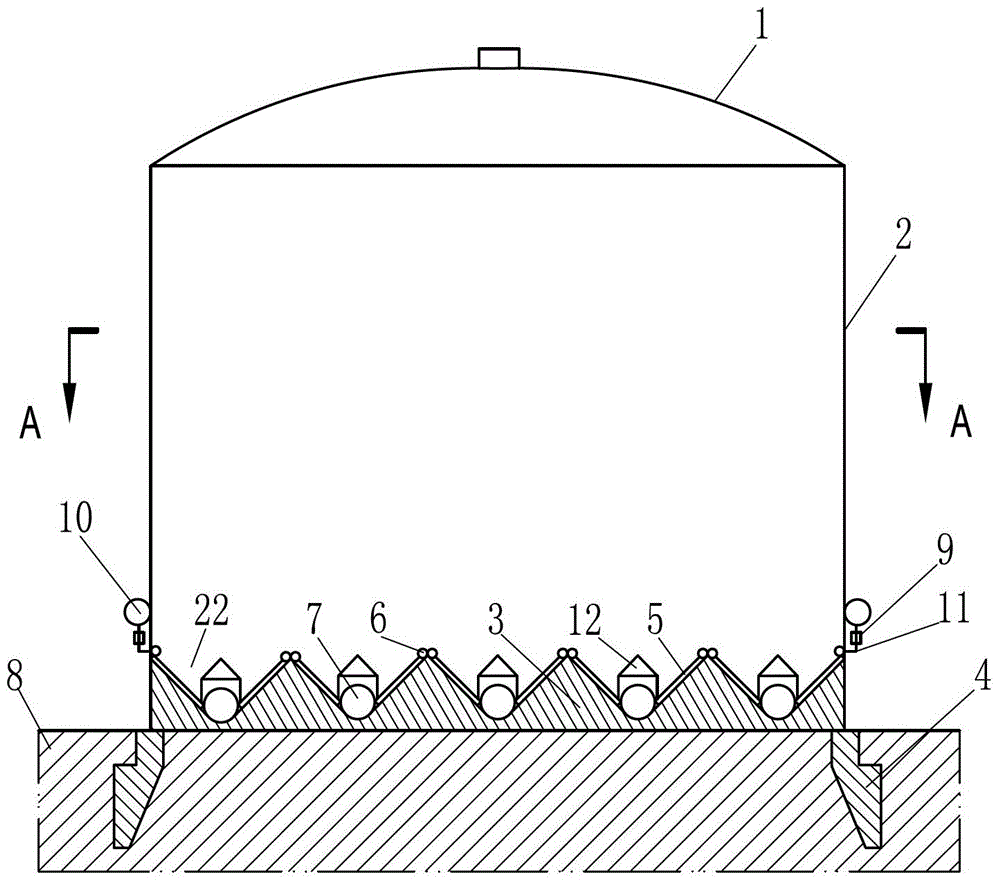

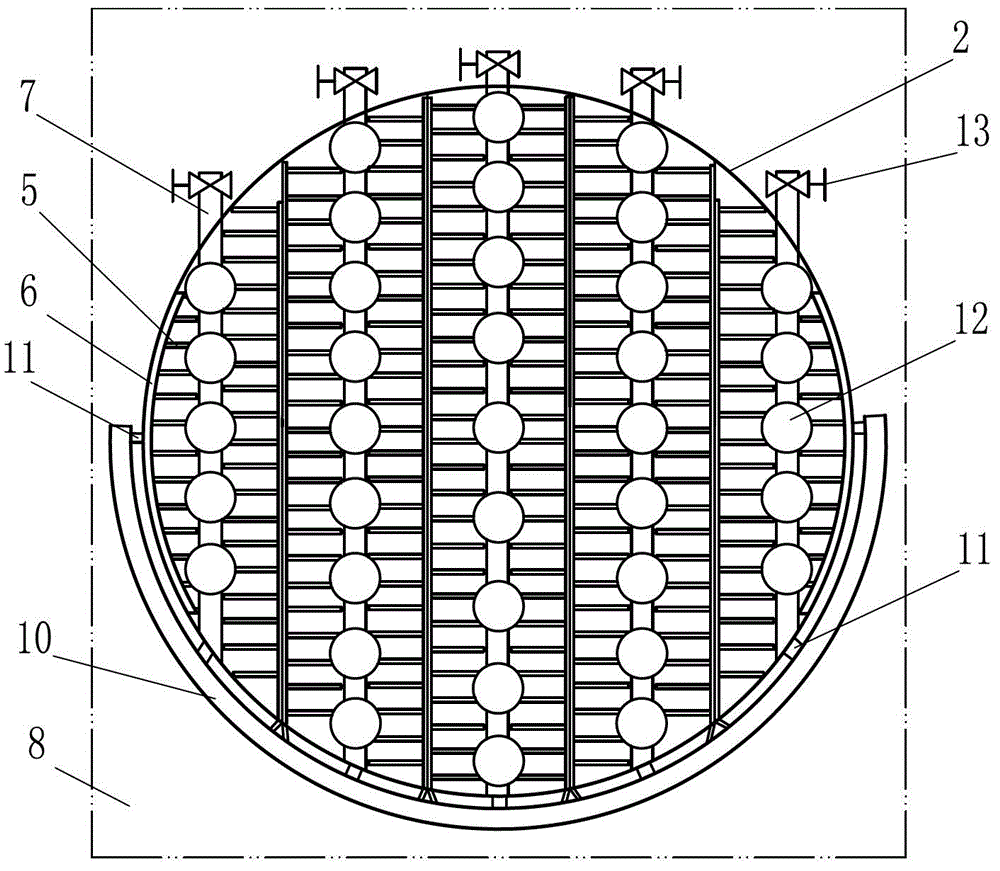

[0026] Such as figure 1 and figure 2 The large-scale floor-standing fluidized storage of the present invention shown in the present invention includes a top 1, a wall 2, a bottom 3 and a foundation 4. A V-shaped bevel 22 is continuously arranged on the upper part of the bottom 3, and the V-shaped groove 22 is along the bottom 3. The radial direction is arranged parallel to each other, and the surface of the slope on both sides of the V-shaped groove 22 is provided with a fluidization rod 5, and the fluidization rod 5 is equipped with an air supply pipeline, which includes a main air supply pipeline 10, a branch air supply pipeline 11 and a delivery Air pipe 6, a valve 9 for controlling gas flow and pressure is set on the branch gas supply pipeline, the air supply pipe 6 is arranged on the top of the slope on both sides of the V-shaped groove 22, and is connected with the fluidization rod 5 provided on the corresponding slope, and the air supply pipe 6 The branch gas supply p...

Embodiment 2

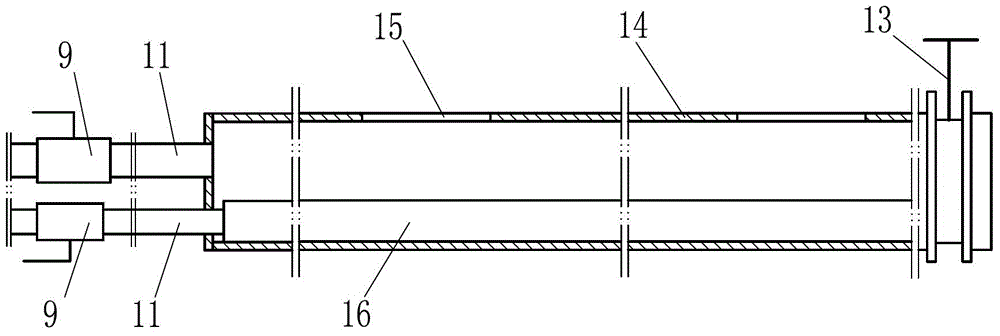

[0039] Such as figure 1 , Figure 4 and Figure 5 The difference between the shown large-scale floor-standing fluidized storage of the present invention and Embodiment 1 is that since the material conveying pipe 14 in the retrieving device 7 arranged in the middle of the bottom 3 of the reservoir is very long, the number of discharge openings arranged on the material conveying pipe More, in order to ensure the transportation of powder materials, an air supply pipeline 21 is set at the center of the bottom of the warehouse 3, and two retrieving devices 7 are installed in the corresponding V-shaped groove 22 in the middle of the bottom of the silo. The glyph groove passes through the bottom of the warehouse wall 2 and extends to the outside of the warehouse, and the air supply pipeline 21 is used to supply air to the material conveying pipe 14 and the pneumatic fluidization rod 16 in the two reclaiming devices 7 respectively. In addition, if Figure 4 and Figure 5 As shown ...

Embodiment 3

[0043] Such as figure 1 , Figure 4 and Figure 6 The difference between the large floor-standing fluidized storage of the present invention and the second embodiment is that in order to meet the needs of long-distance horizontal feeding, the material delivery pipe 14 in the retrieving device 7 can also be provided with a forward guide corresponding to the discharge port 15 The deflector 20 gradually slopes downward along the discharge direction of the material conveying pipe 14 along the deflector 20 .

[0044] Compared with Embodiment 2, in the reclaiming device 7 of the large-scale floor-standing fluidized storage described in this example, a forward deflector 20 is added at the discharge port 15 of the material delivery pipe 14, which can weaken the pneumatic fluidization. The impact of the rod 16 on the blanking during work, the conveying of the powder in the material conveying pipe 14 is also more smooth. The flow velocity of the airflow blown in by the air supply pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com