Slow rebound sponge and preparation method thereof

The technology of slow rebound sponge and slow rebound polyether is applied in the field of slow rebound sponge and its preparation, which can solve the problem of weak tensile force, hardness, tear strength, etc. The quality of the elastic sponge and other issues can achieve the effect of consolidating stability, unique sound absorption performance, and good resilience performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

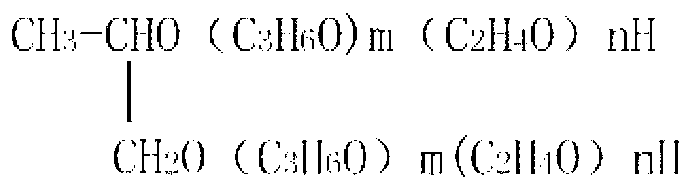

Method used

Image

Examples

Embodiment 1

[0045] The slow rebound sponge in this example is prepared from the following raw materials according to the weight ratio: 50 parts of ordinary polyether; 50 parts of ordinary polyether hardening agent; 10 parts of slow rebound polyether; 90 parts of slow rebound polyether 8 parts of melamine; 30 parts of toluene diisocyanate; 3 parts of methylene chloride; 2.5 parts of water; 0.2 parts of the first catalyst; 0.2 parts of the second catalyst; 0.01 parts of foam stabilizer;

Embodiment 2

[0047] The slow rebound sponge in this example is prepared from the following raw materials according to the weight ratio: 80 parts of ordinary polyether; 20 parts of ordinary polyether hardening agent; 50 parts of slow rebound polyether; 50 parts of slow rebound polyether 30 parts of melamine; 60 parts of toluene diisocyanate; 10 parts of dichloromethane; 6 parts of water; 0.8 parts of the first catalyst; 0.6 parts of the second catalyst; 0.5 parts of foam stabilizer; 1.5 parts of dyeing agent.

Embodiment 3

[0049] The slow rebound sponge in this example is prepared from the following raw materials according to the weight ratio: 25 parts of ordinary polyether; 75 parts of ordinary polyether hardening agent; 25 parts of slow rebound polyether; 75 parts of slow rebound polyether 20 parts of melamine; 65 parts of toluene diisocyanate; 6.5 parts of methylene chloride; 4 parts of water; 0.5 parts of the first catalyst; 0.4 parts of the second catalyst; 0.3 parts of diethanolamine; 0.2 parts of foam stabilizer;

[0050] The embodiment of the present invention also provides the production process and process of the slow rebound sponge.

[0051] In the embodiment of the present invention, a one-step box-type foaming method is adopted in the production of sponge, and various raw materials are quickly added to the forming box under high-speed stirring, and reactions such as chain growth, foaming, crosslinking, and curing are completed in the forming box. Thereby completing the sponge produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com