Production method of acidic blue dye containing active groups

A technology of blue dyes and reactive groups is applied in the production field of acid blue dyes containing reactive groups, which can solve the problems of high sewage treatment cost, easy product deterioration and loss, and high operation requirements, so as to reduce the content of wastewater. , The effect of improving acid resistance and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

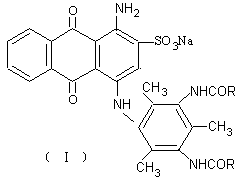

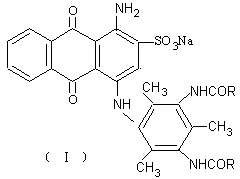

[0024] A method for producing an acid blue dye containing active groups, the structure of the compound is shown in the following formula (I): , where R is -CH 3 ,

[0025] Including the following process steps: a condensation reaction step and a neutralization reaction step,

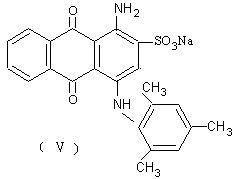

[0026] Condensation reaction steps: put 900kg of sulfuric acid with a concentration of 98% into the condensation reactor, add 250kg of the original powder of formula (Ⅴ) and keep stirring for 1 hour, cool down to 20~25°C, add 116kg of compound of formula (Ⅲ), keep stirring for 5 hours , to obtain the compound of formula (Ⅳ), after the end point is reached, dilute it into 3500kg of ice water, the dilution temperature will be less than 10°C, after dilution, stir it evenly and press filter to obtain a filter cake, and the filtrate is recycled to the treatment kettle;

[0027] Neutralization reaction steps: put 2000kg of ice water into the neutralization reaction kettle, add the filter cake, adjust the te...

Embodiment 2

[0029] A method for producing an acid blue dye containing active groups, the structure of the compound is shown in the following formula (I): , where R is -CH 2 Br,

[0030] Including the following process steps: a condensation reaction step and a neutralization reaction step,

[0031] Condensation reaction steps: put 1200kg of sulfuric acid with a concentration of 95% into the condensation reactor, add 250kg of the original powder of formula (Ⅴ) and keep stirring for 1 hour, cool down to 20~25°C, add 125kg of compound of formula (Ⅲ), keep stirring for 4 hours , to obtain the compound of formula (Ⅳ), after the end point is reached, dilute it into 4000kg of ice water, the dilution temperature will be less than 8°C, after dilution, stir it evenly for a while and press filter to obtain a filter cake, and the filtrate is recycled to the treatment kettle;

[0032] Neutralization reaction steps: put 2000kg of ice water into the neutralization reaction kettle, add the filter cake,...

Embodiment 3

[0034] A method for producing an acid blue dye containing active groups, the structure of the compound is shown in the following formula (I): , where R is -C 6 h 5 ,

[0035] Including the following process steps: a condensation reaction step and a neutralization reaction step,

[0036] Condensation reaction steps: put 1600kg of sulfuric acid with a concentration of 90% into the condensation reactor, add 250kg of the original powder of formula (Ⅴ) and keep stirring for 1 hour, cool down to 20~25°C, add 135kg of compound of formula (Ⅲ), keep stirring for 3 hours , to obtain the compound of formula (Ⅳ), after the end point is reached, dilute it into 4500kg of ice water, the dilution temperature will be less than 5°C, after dilution, stir evenly for a while and press filter to obtain a filter cake, and the filtrate is recycled to the treatment kettle;

[0037] Neutralization reaction steps: put 2000kg of ice water into the neutralization reaction kettle, add the filter cake, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com