Energy-saving rolling method of low alloy steel based on critical temperature

A low-alloy steel, critical temperature technology, applied in the field of hot-rolled strip production, to achieve the effect of reducing heating temperature, reducing heating energy consumption, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

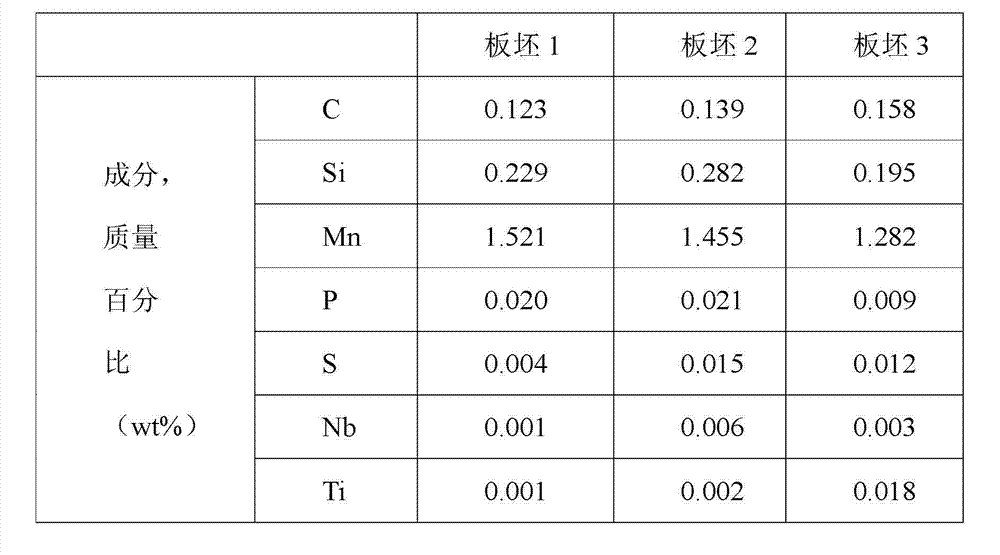

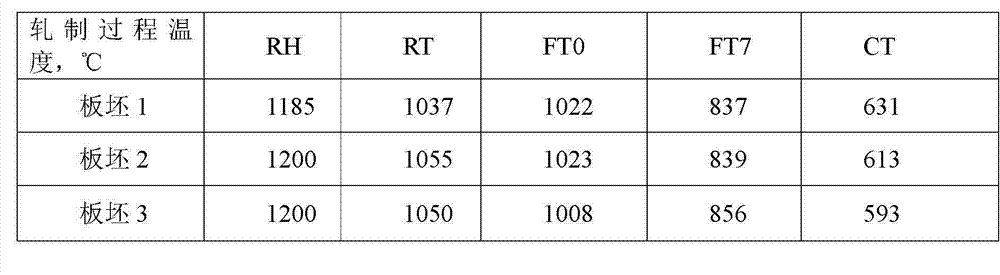

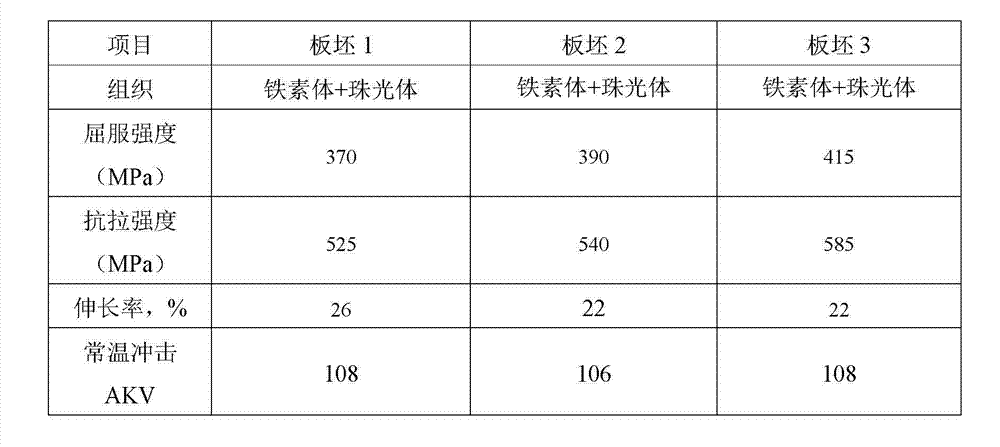

[0021] The present invention will be further described in detail below in conjunction with specific embodiments:

[0022] The heating temperature during the conventional hot-rolled strip rolling process and the rolling process temperature are generally high. Therefore, in the actual hot-rolled strip production process, the excessive heating temperature causes the energy consumption of the slab in the heating furnace. More. The present invention proposes a low-alloy steel energy-saving rolling method based on the critical temperature. The method determines the critical temperature of the required rolling process on the basis of ensuring the mechanical properties of the original low-alloy steel slab, and based on the critical temperature Work out the rolling method of low alloy steel. The critical temperature of the low alloy steel slab rolling process is determined by the following formula:

[0023] Critical temperature determination formula:

[0024] RH=Max[T(hot brittle), T(C sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com