Automatic ramie coat fiber stamping machine

A technology of skin fiber and hemp machine, applied in the directions of fiber mechanical separation, fiber processing, mechanical processing, etc., can solve the problems of high labor intensity, unsafe, time-consuming and labor-intensive, etc., and achieves reduced labor intensity, high work efficiency, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

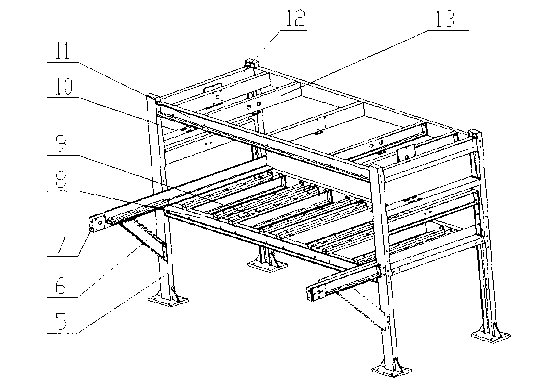

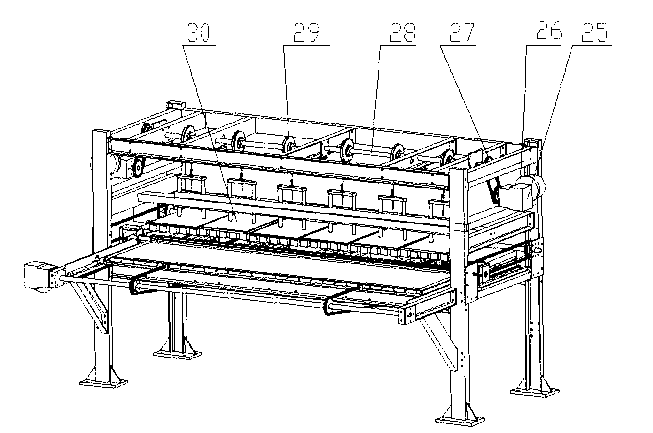

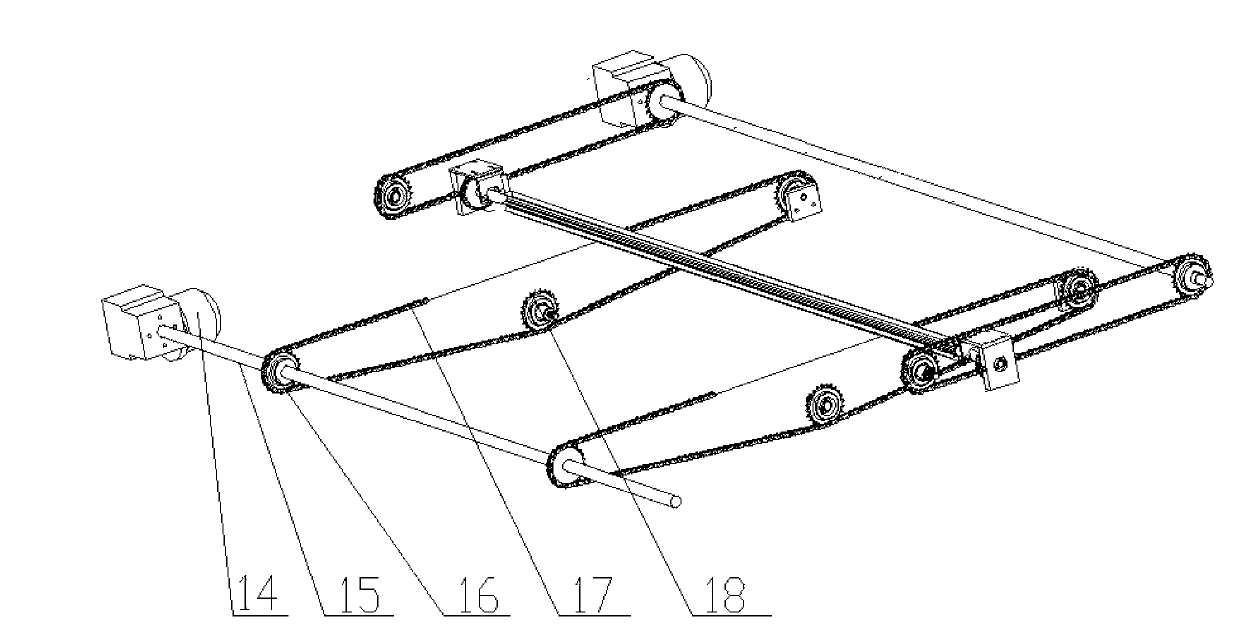

[0024] The automatic ramie skin fiber copying machine of the present invention is a kind of copying machine that sends hemp longitudinally and can realize the automation of the hemp fiber degumming process. position, the electromagnetic clutch works to drive the hammer to knock, and after working for a period of time, the knock stops, the turning mechanism moves, flips the ramie fiber, and knocks again. Institutions withdraw hemp fiber. The whole machine adopts a linkage transmission system to make all the working parts operate synchronously. The ramie fiber is placed on the platform. The transmission mechanism makes the ramie move back and forth longitudinally, and then the hammer body strikes up and down. There is an automatic hemp turning device, which allows the hemp rack to move horizontally, so that the automation of the hemp feeding, hemp feeding and hemp fiber degumming process can be realized, which greatly improves the work efficiency.

[0025] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com