Sludge removing device of hydraulic excavator

A hydraulic excavator and mud removal technology, which is applied in the direction of earth mover/shovel, wellbore/well components, earthwork drilling, etc., can solve problems such as poor mud removal work, and achieve a wide range of reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

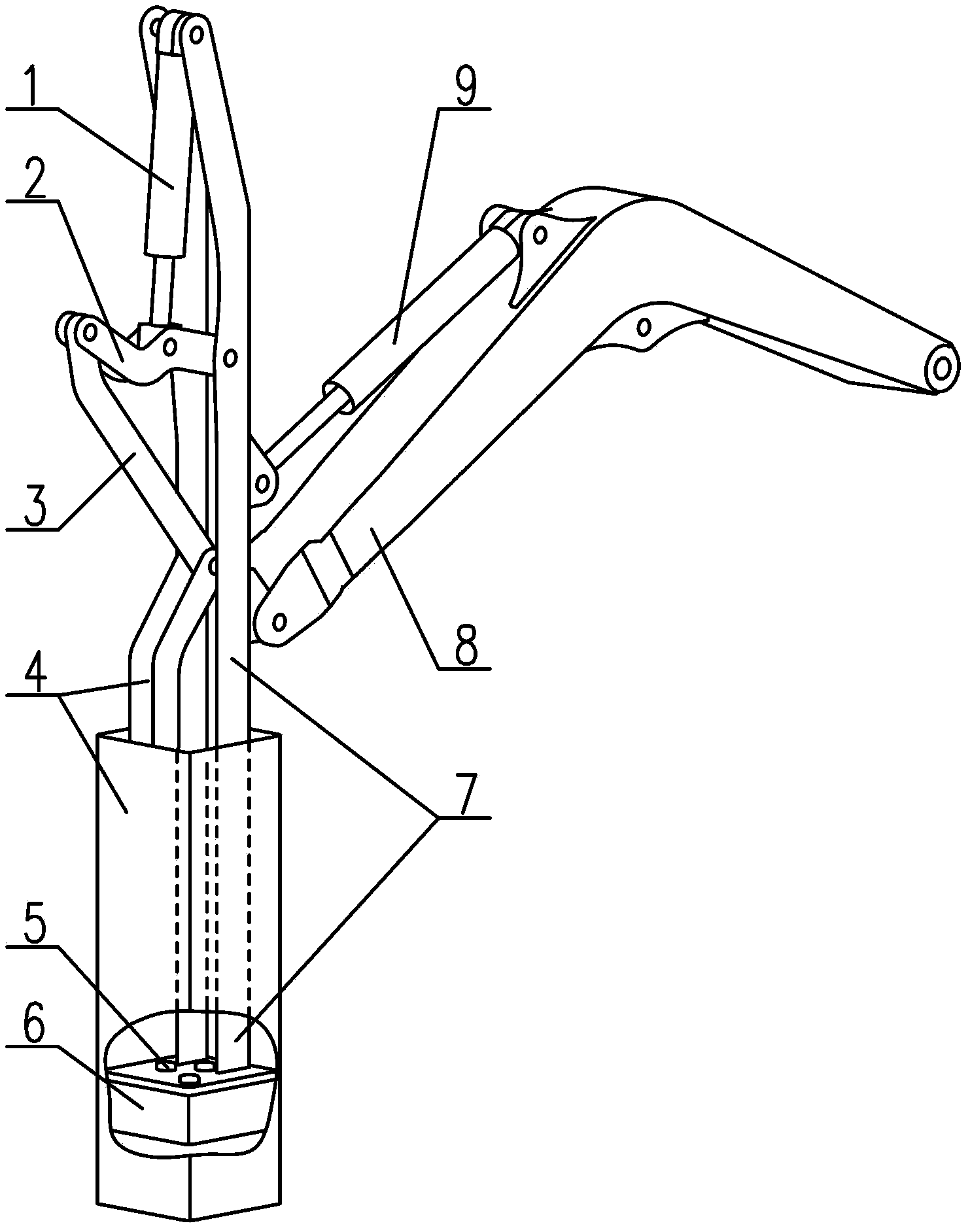

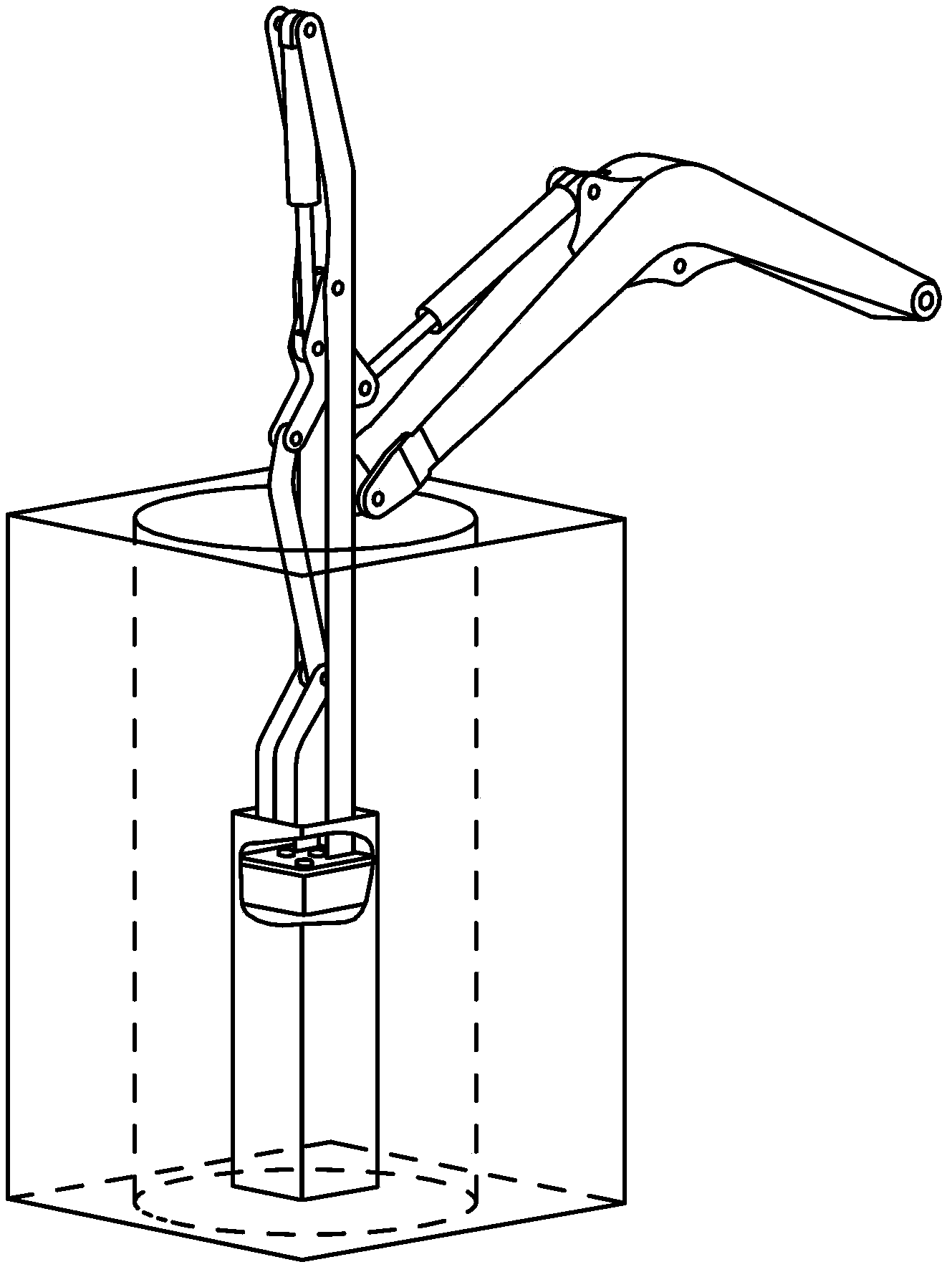

[0012] The technical solutions of the present invention are further described below by means of the accompanying drawings and examples.

[0013] like figure 1 As shown, the hydraulic excavator mud removal device of the present invention includes a push cylinder 1, a crank 2, a connecting rod 3, a mud removal cylinder 4, a screw 5, a piston 6 and a mast 7, and is characterized in that the push cylinder 1 is an excavation The rest of the bucket oil cylinder of the machine, one end hinge point is flexibly connected with the mast 7, and the other end hinge point is flexibly connected with the crank 2, which is used to drive the crank 2 to rotate, and its stroke is small; one end hinge point of the crank 2 is flexibly connected with the mast 7 , the middle hinge point is movably connected with the push cylinder 1, the other end hinge point is movably connected with the connecting rod 3, one end hinge point of the connecting rod 3 is movably connected with the crank 2, the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com