Construction technology of inorganic glass bead heat preservation outer wall

A technology of inorganic vitrified microbeads and construction technology, applied in thermal insulation, building components, construction, etc., to achieve convenient construction and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

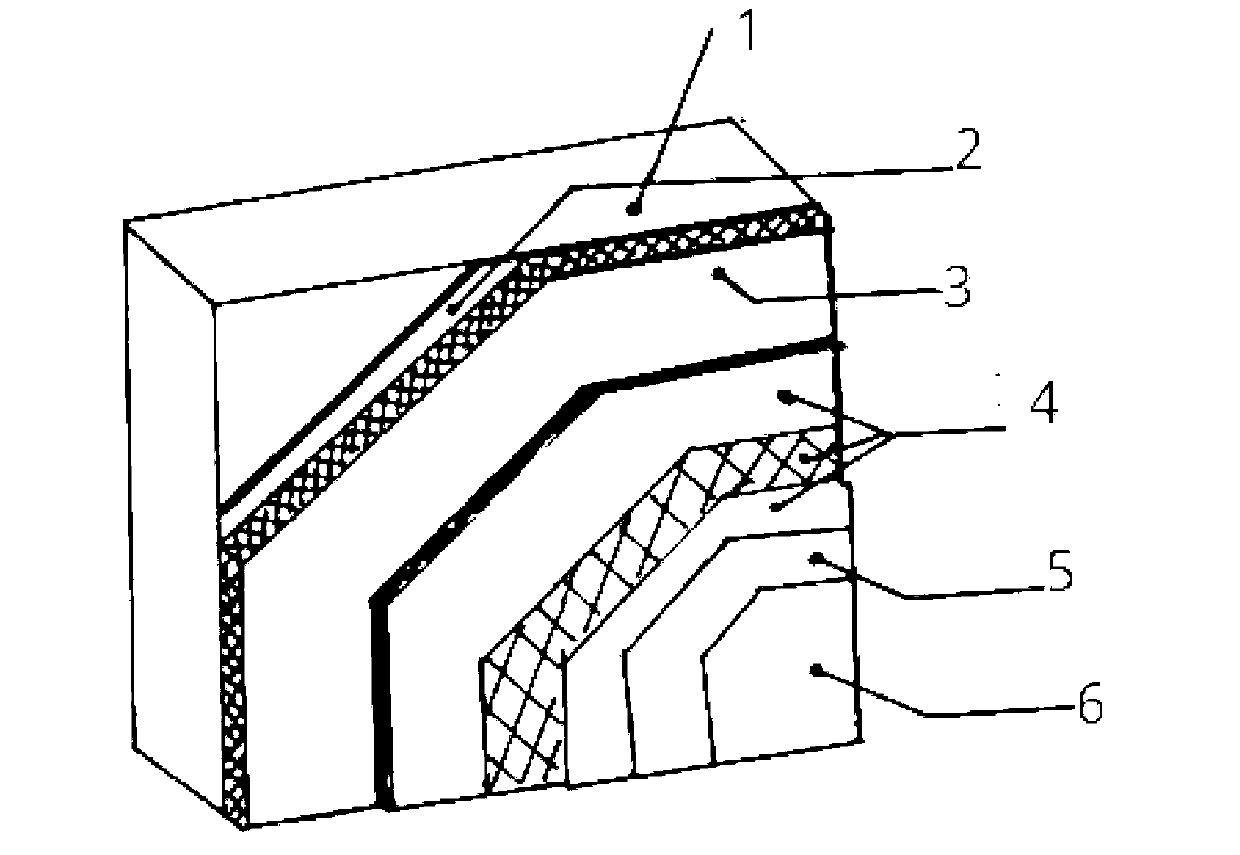

[0017] Combine below figure 1 Specifically explain the structure of the inorganic vitrified microbead outer wall, which includes a wall 1, which is successively laid with an interface agent bonding treatment layer 2, an inorganic vitrified microbead thermal insulation mortar layer 3, and anti-cracking mortar protection reinforcement Layer 4, flexible water-resistant putty layer 5, finishing layer 6.

[0018] The construction process of the inorganic vitrified microbead thermal insulation exterior wall includes the following steps:

[0019] 1) Spray or wipe the interface agent bonding treatment layer on the wall surface that has been treated at the base;

[0020] 2) Suspension line and play control line;

[0021] 3) Apply the inorganic vitrified microbead thermal insulation mortar layer. The inorganic vitrified microbead thermal insulation mortar layer is applied twice, and the thickness of each application is not greater than 20mm.

[0022] The first pass of plastering: on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com