Surface smoothing mechanism and robot with same

A technology of a rubbing head and a driving mechanism, which is applied in the field of robots, can solve the problems of difficulty in mastering skills, low construction efficiency, and high labor intensity of workers, and achieve the effects of ensuring construction quality, improving work efficiency, and improving construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

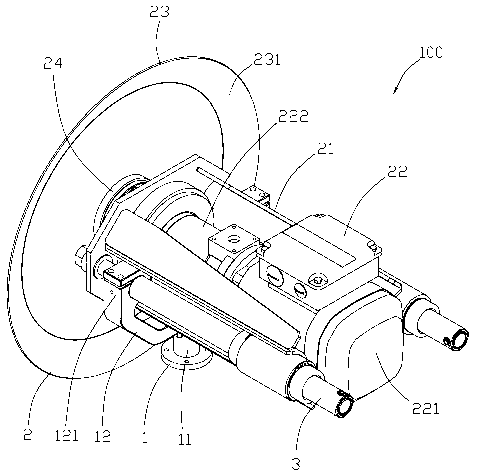

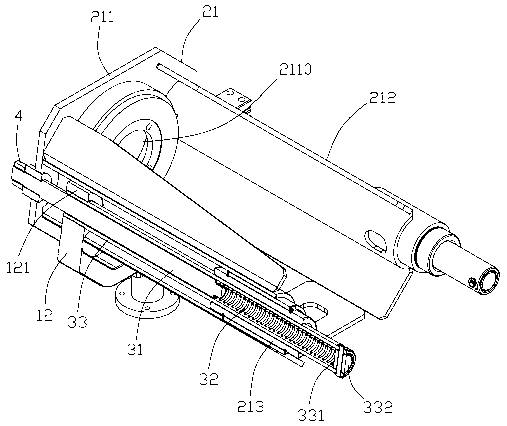

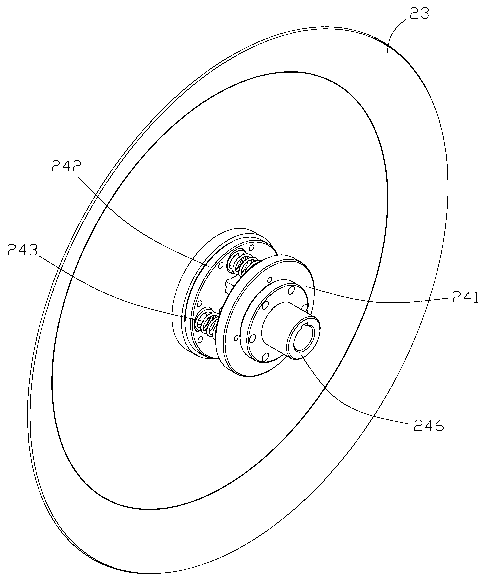

[0022] Please refer to Figure 1 to Figure 4 Shown is a preferred embodiment of the noodle rubbing mechanism 100 of the present invention. combine Figure 5 As shown, the surface rubbing mechanism 100 of the present invention is suitable for a robot 800 for automatically rubbing and smoothing the mortar on the indoor wall. The robot 800 includes a body 81, a walking mechanism 80 fixed below the body 81, a lumbar joint 82 movably fixed on the body 81, a mechanical arm 83 movably fixed on the lumbar joint 82, a driving lumbar joint 82 and mechanical The driving device (not shown) for the working of the arm 83, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com