Programmable logic controller (PLC) based monitor and control generated system (MCGS) heat pump monitoring system and control method thereof

A technology for monitoring systems and hot water systems, which is applied to fluid heaters, lighting and heating equipment, etc. It can solve the problems that the main parameters cannot be seen at a glance, the control of air source heat pump water heaters is not involved, and the handheld device cannot be centrally managed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

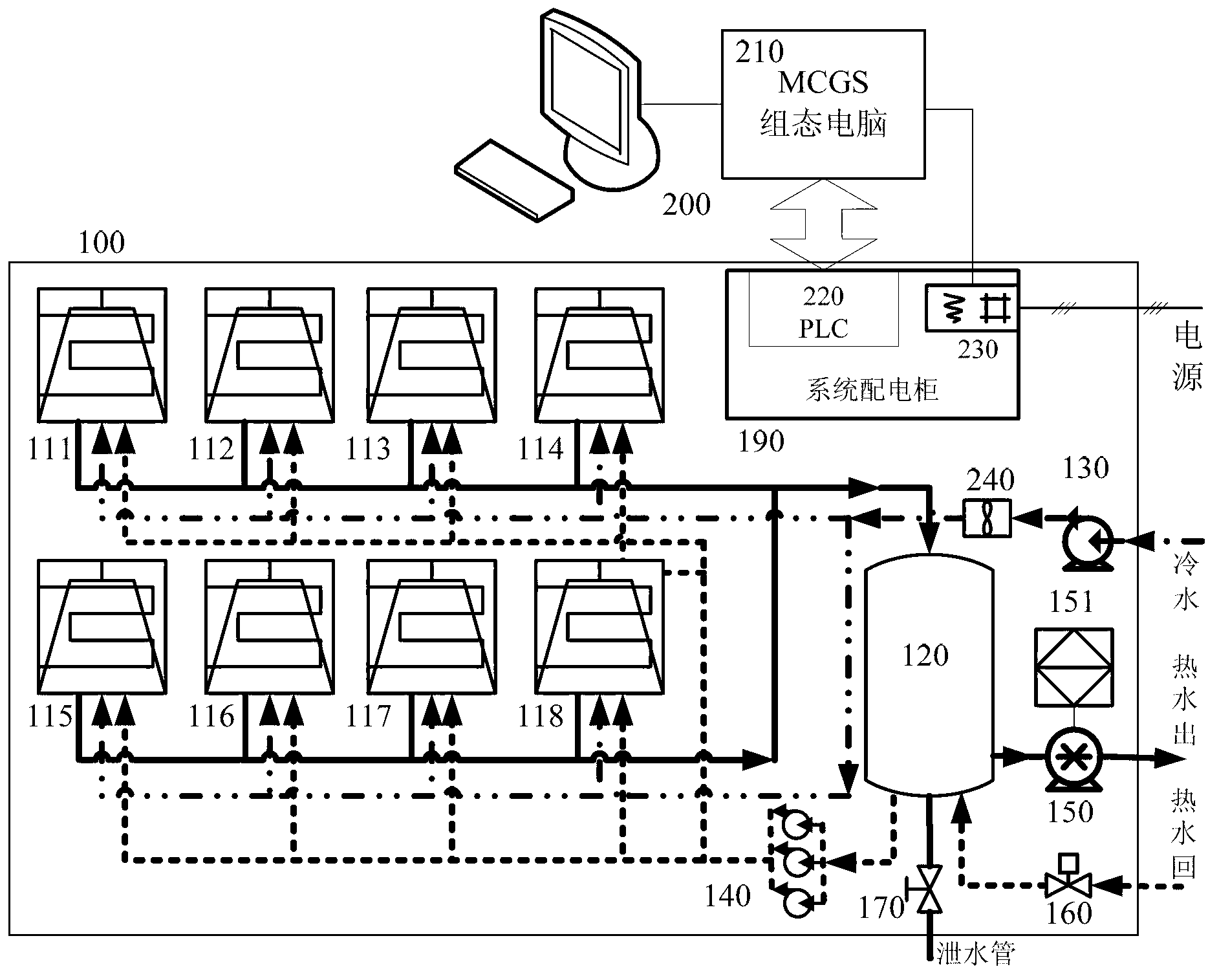

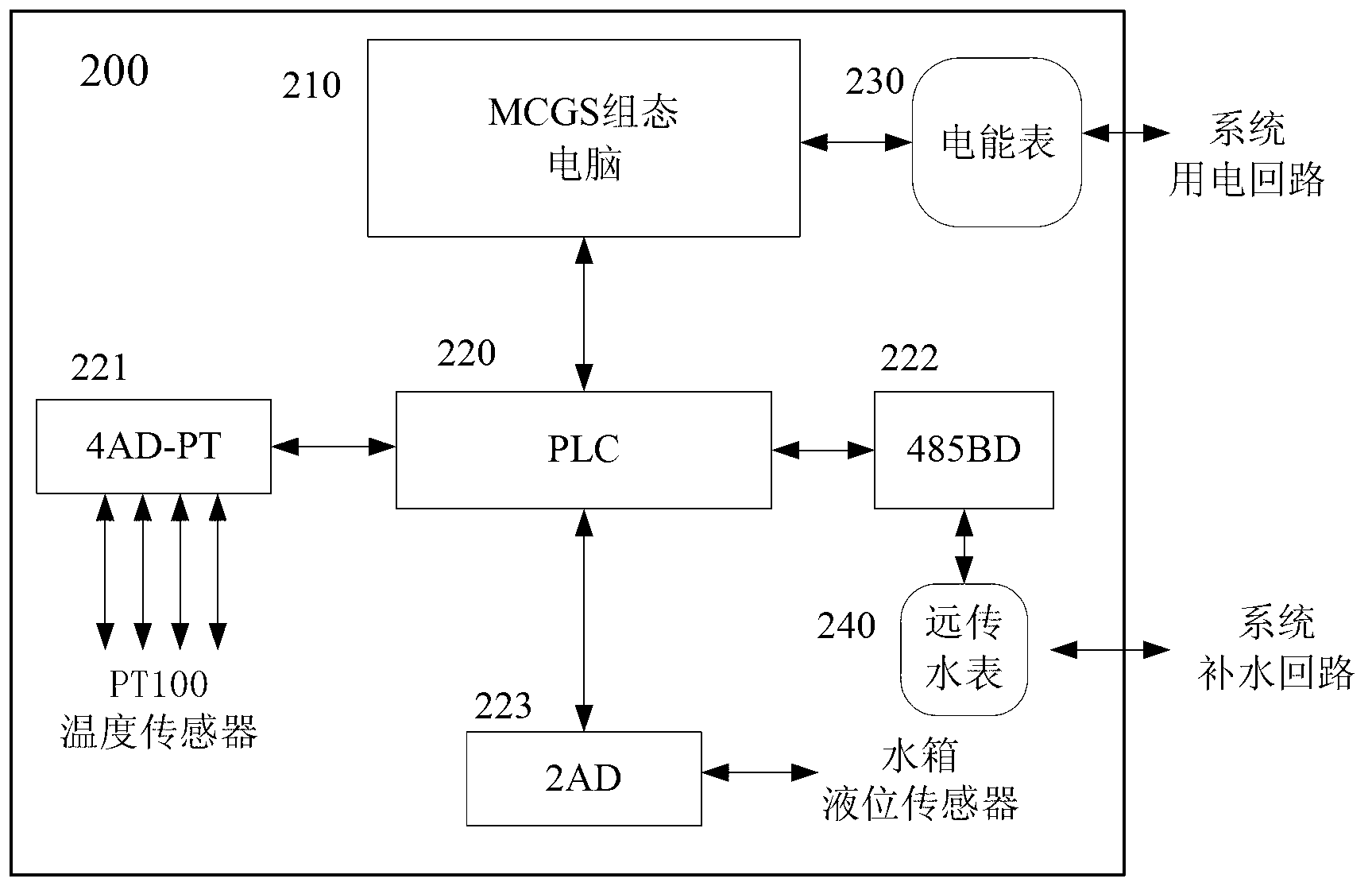

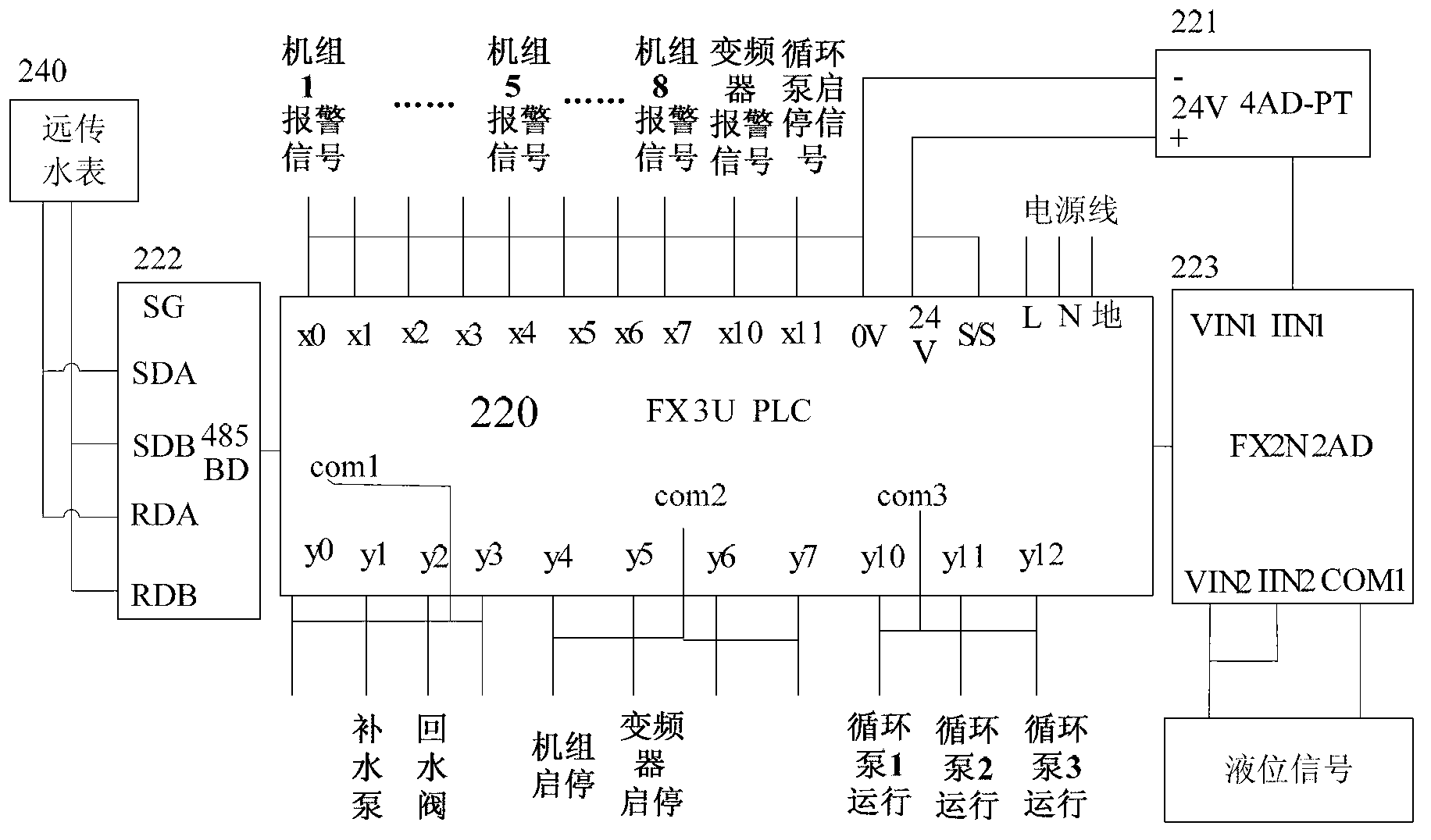

[0049] The MCGS heat pump monitoring system based on PLC is composed of upper computer, unit main board, electrical execution equipment and sensors, etc. The upper computer is responsible for real-time monitoring of the entire system, and the unit main board is connected to the heat pump hot water system through sensors to complete on-site data collection and transmission. , realize the multi-level control of the system, and make the control function more powerful. figure 1 It is an embodiment of the heat pump hot water system using the PLC-based MCGS heat pump monitoring system of the present invention. The heat pump hot water system 100 includes at least two sets of heat pump units, a water tank 120, a supplementary water pump 130, a circulation pump 140, and a hot water booster pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com