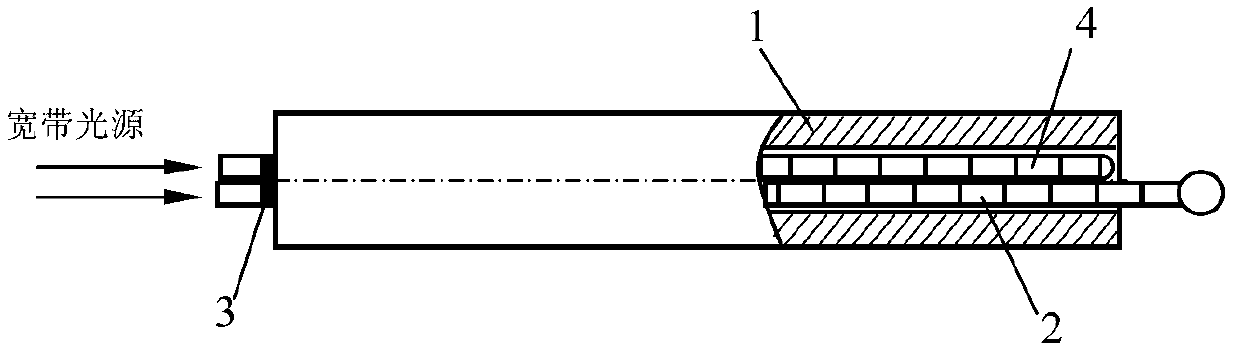

Ultra-precision micro-displacement sensing system and processing method based on double-FBG suspended type probe structure

A sensing system and suspension technology, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the unfavorable ultra-precision measurement of the size and parameters of micro-nano devices, the fiber Bragg grating is brittle and easy to break, and the size and structure are large, etc. problem, to achieve the effect of small measuring force, compact structure and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1. Probe head preparation technology

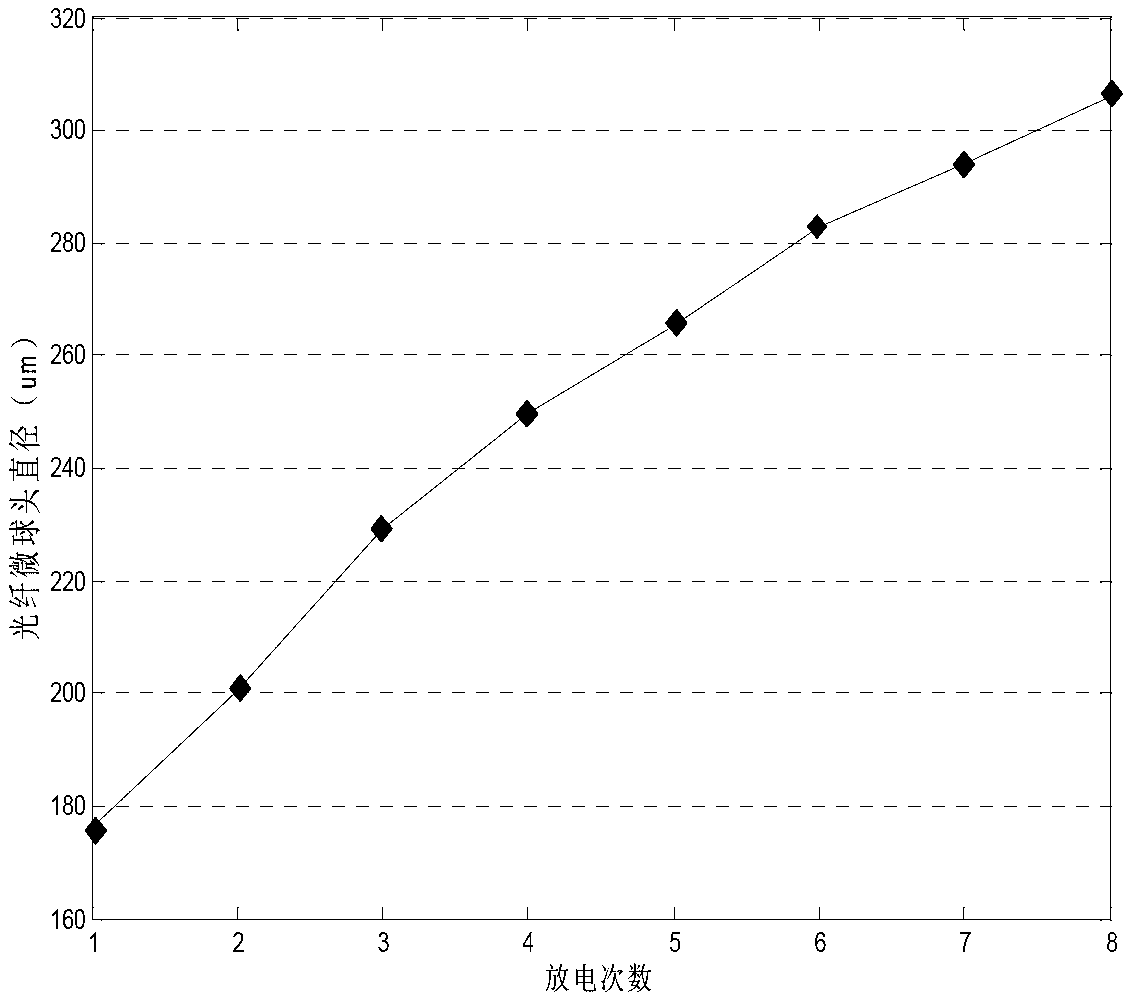

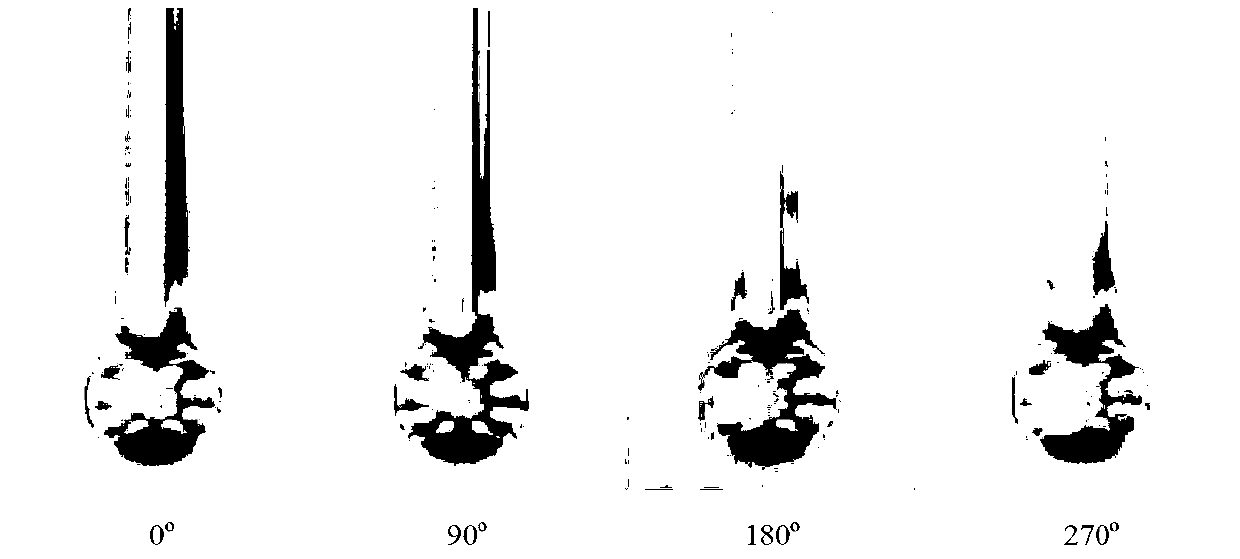

[0031] Modern precision machining technology develops the processing of measuring balls towards a smaller diameter, so as to adapt to the measurement of micro-scale of micro-nano devices. In order to meet the requirements of micro-size measurement of micro-devices, the micro-probe ball head is prepared according to the micro-meter ball electric discharge machining principle and the optical fiber melting and burning process principle of the present invention. In the experiment, the glass optical fiber material was used, and the melting discharge mechanism of the optical fiber fusion splicer was used. The optical fiber head melted rapidly after absorbing the spark discharge energy. According to the physical phenomenon of the surface tension contraction of the molten liquid, the molten part of the optical fiber gradually formed a spherical shape during the solidification process, so that The end face of the fiber naturally forms a tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com