Minute size measuring device based on embedded system

An embedded system, micro-size technology, applied in measuring devices, components of TV systems, components of color TVs, etc. Interference and other problems, to achieve the effect of low power consumption, low volume and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

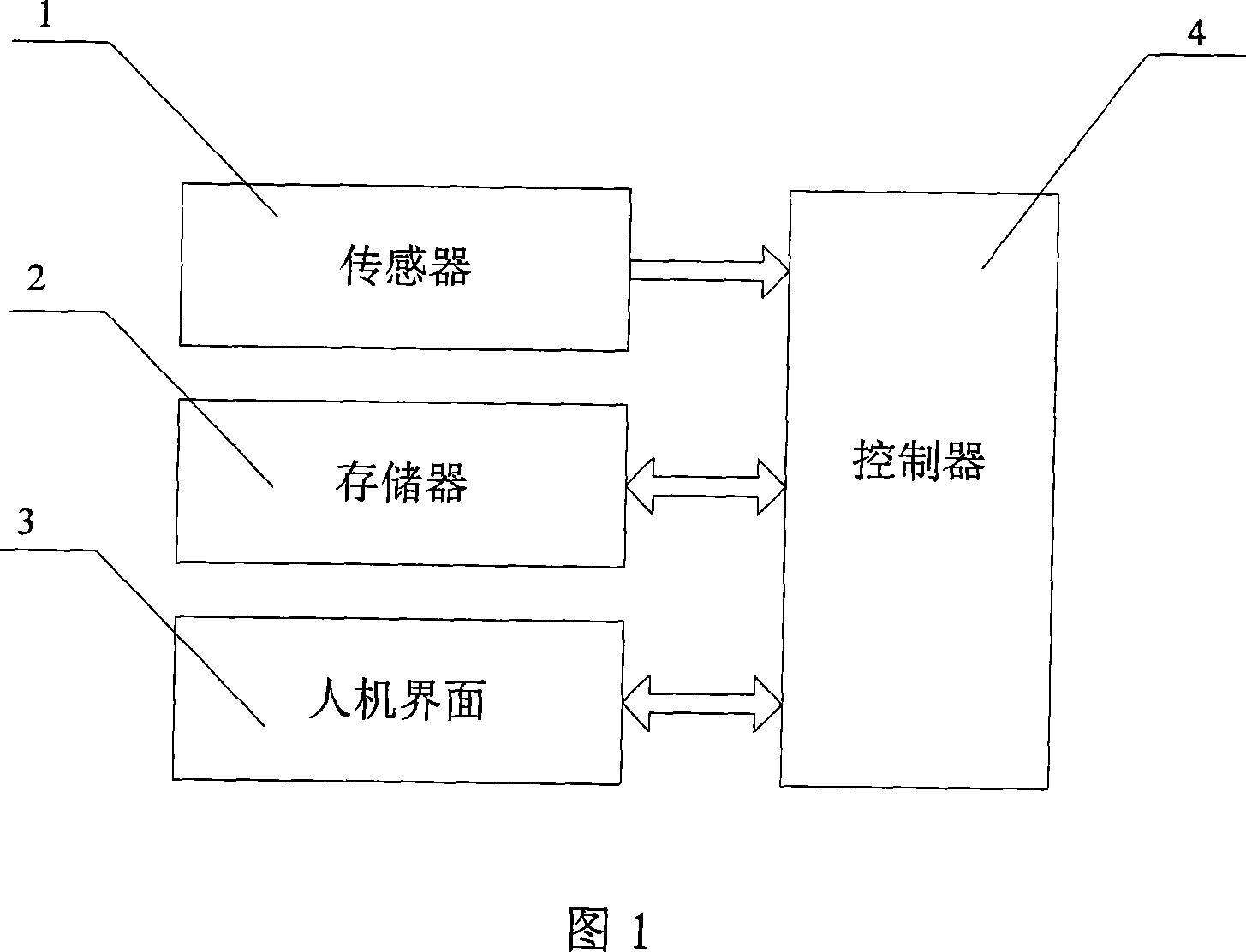

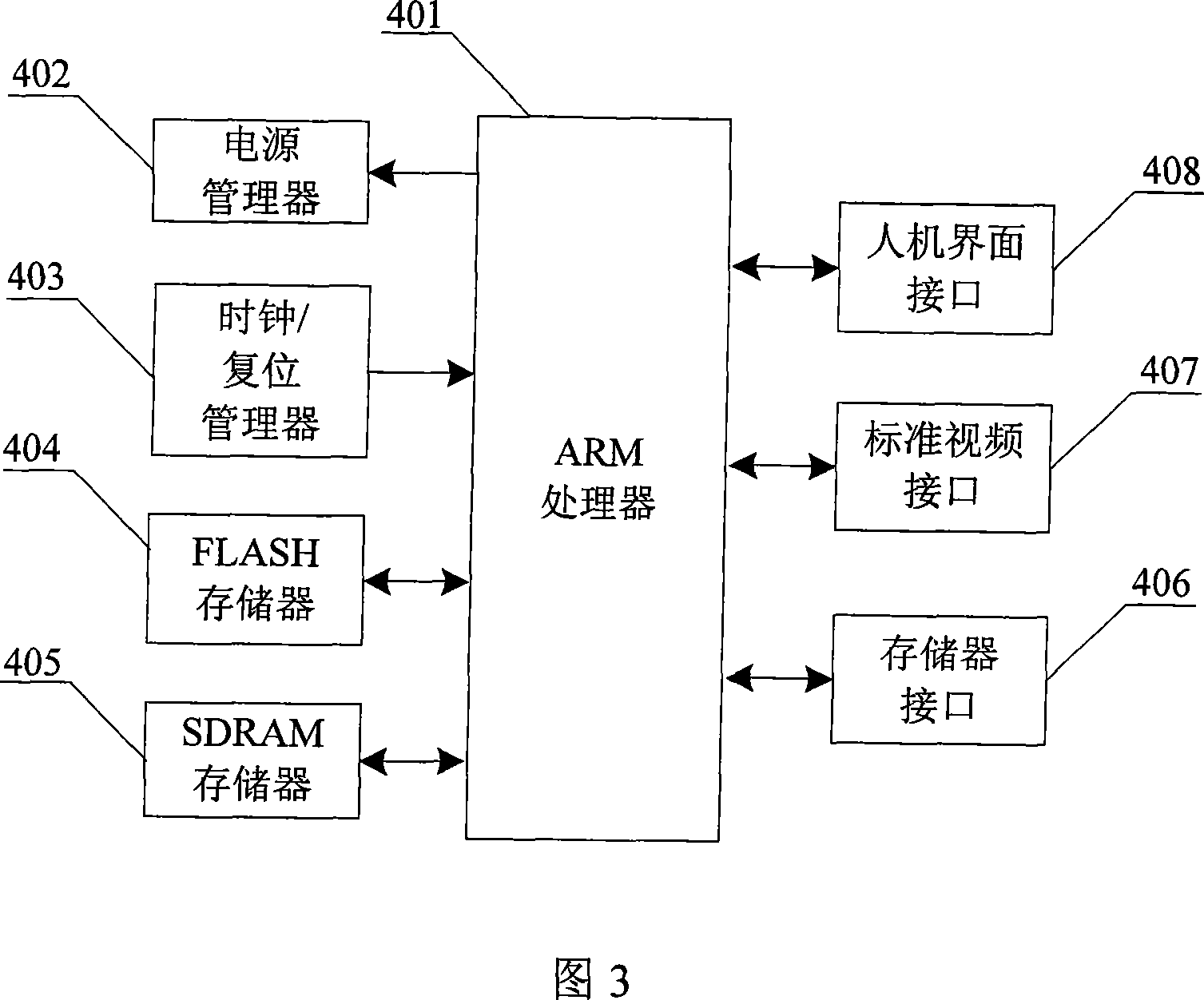

[0018] As shown in Figure 1, the present invention is made up of sensor 1, memory 2, man-machine interface 3 and embedded controller 4; Wherein sensor 1 is used for collecting the digital image of micro-size amount; Memory 2 is used for storing digital image; Man-machine Interface 3 provides an operating platform for operators to input measurement parameters and commands and display measurement results; controller 4 controls the working process of the entire measurement device, and obtains small-sized values through image processing algorithms. The ITU-R BT.601 / 656 standard digital video interface is used to connect the sensor 1 and the embedded controller 4, and the embedded controller 4 obtains the digital image collected by the sensor 1 and sends it to the man-machine interface 3 for display; After the embedded controller 4 obtains the measurement parameters input by the man-machine interface 3, the embedded controller 4 calculates the magnitude value of the tiny size acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com