Method for preparing exposure curve for radiographic inspection

A technology of exposure curve and production method, which is applied in optics, measuring device, sensitivity measurement process, etc., can solve the problem of time-consuming and labor-intensive processing, and achieve the effect of saving time and labor and saving film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] 1. Exposure:

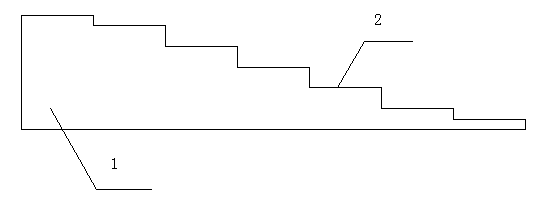

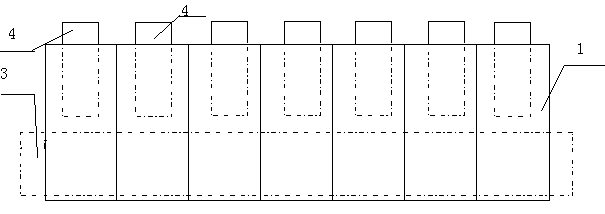

[0021] Under the condition that the X-ray machine, film, intensifying screen, focal length, and darkroom processing conditions remain unchanged, the ladder test block 1 is transilluminated at a fixed exposure (mA·min). Before the transillumination, the film 3 is pressed under the stepped test block 1, and at the same time, the radiation dosimeter 4 capable of measuring the cumulative dose is placed under the steps 2 of different thicknesses of the stepped test block 1, and the cumulative dose data is cleared. Different cumulative doses Corresponds to the thickness of the corresponding stepped test block 1. The image quality meter and intensifying screen are placed according to normal transillumination exposure.

[0022] 2. Post-exposure treatment

[0023] Rinse and dry the exposed film 1, and use a blackness m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com