Patents

Literature

40results about "Sensitometric processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

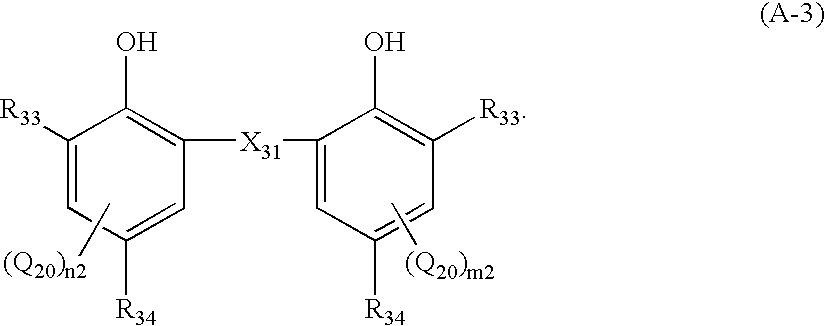

Photothermographic imaging material and method for forming image

InactiveUS7018790B2High densityEnhance the imageDiffusion transfer processesX-ray/infra-red processesImage formationLeuco dye

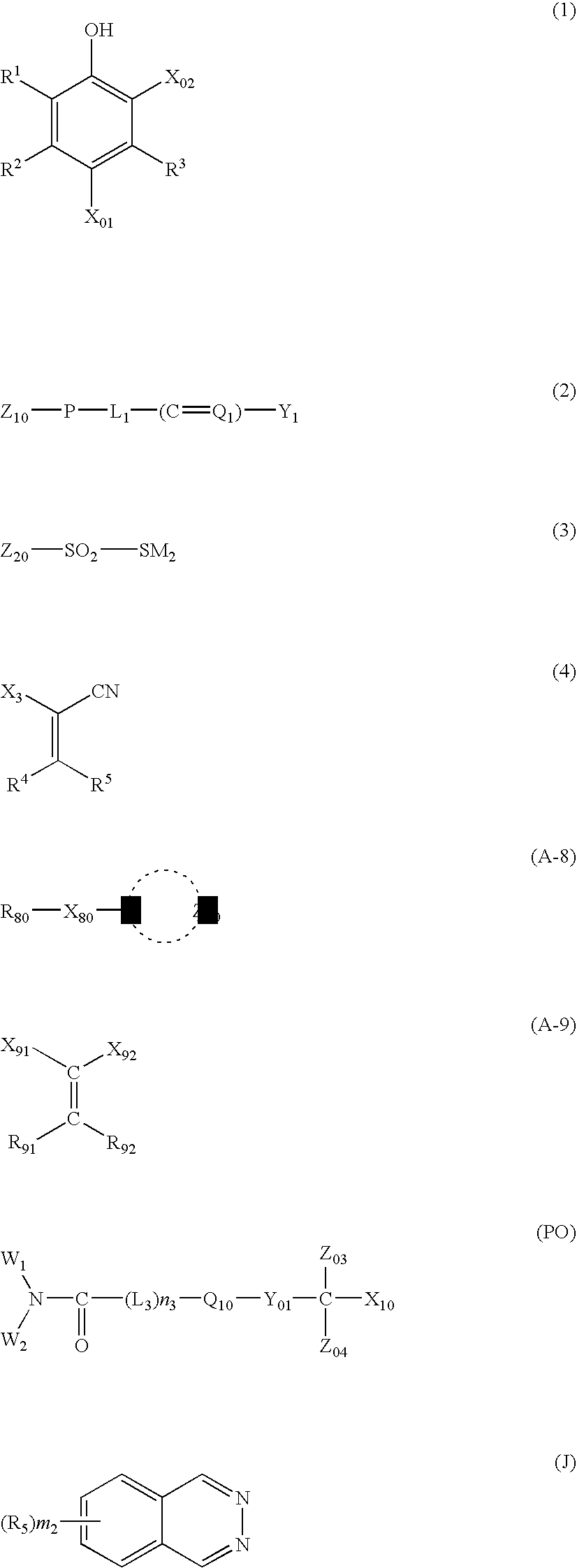

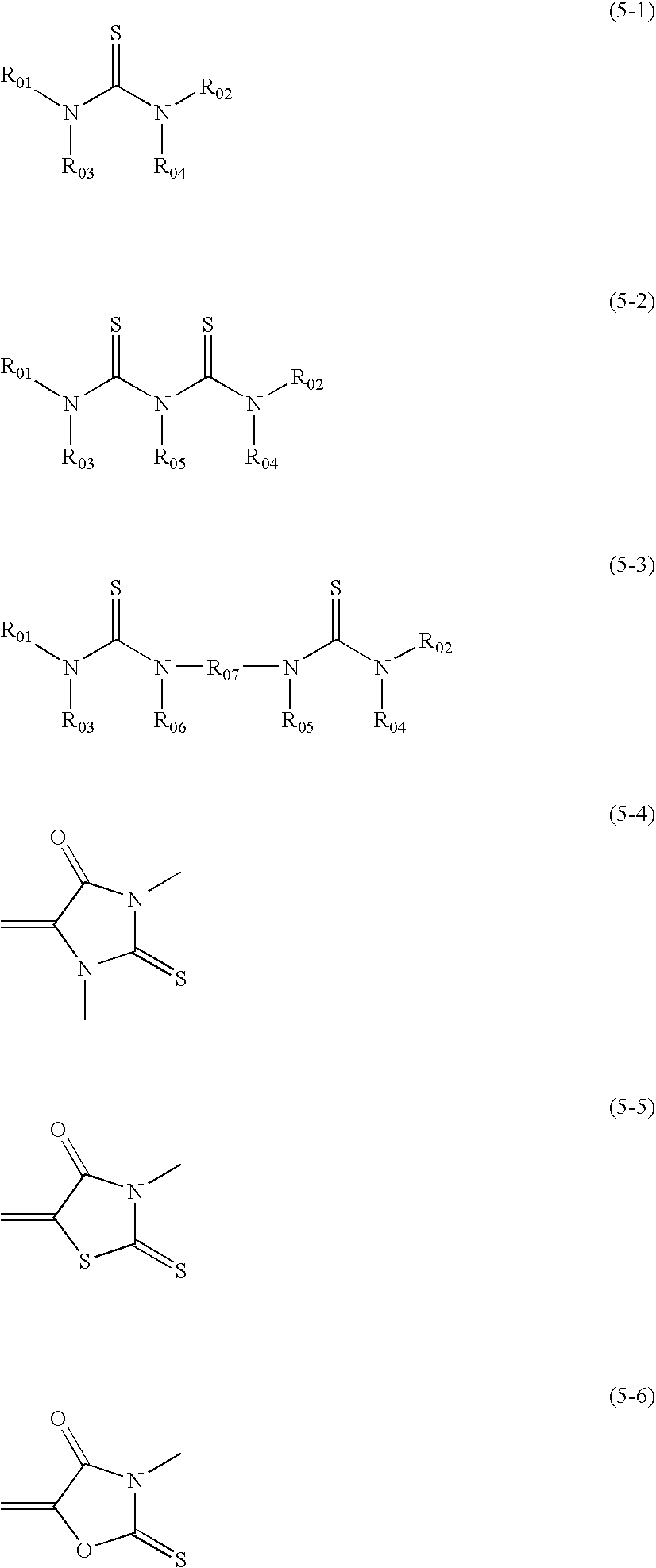

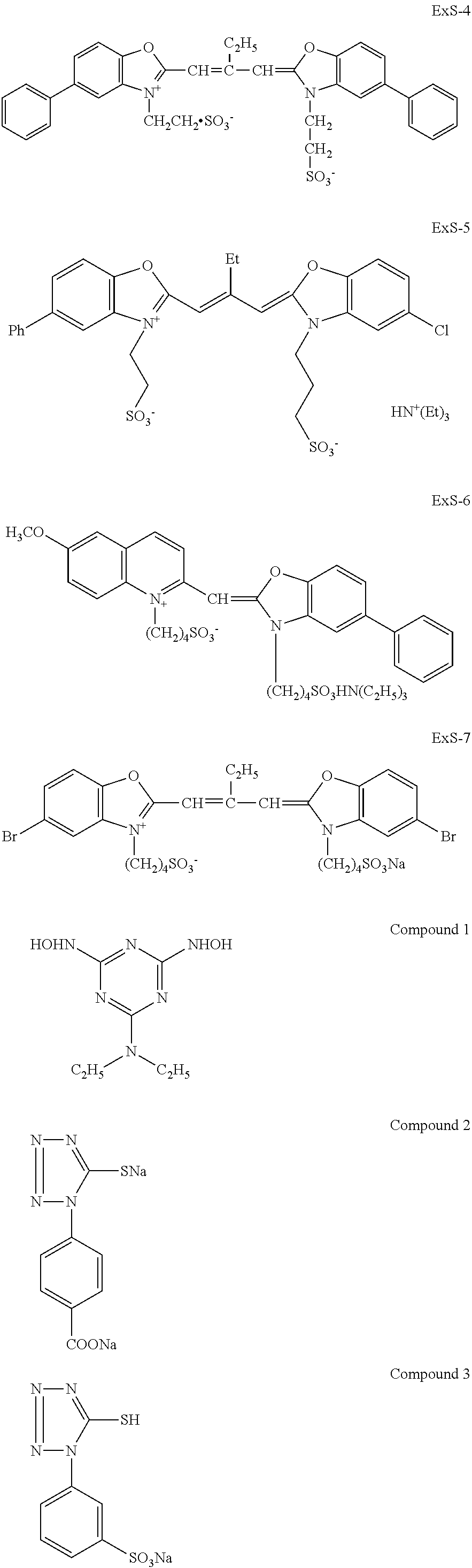

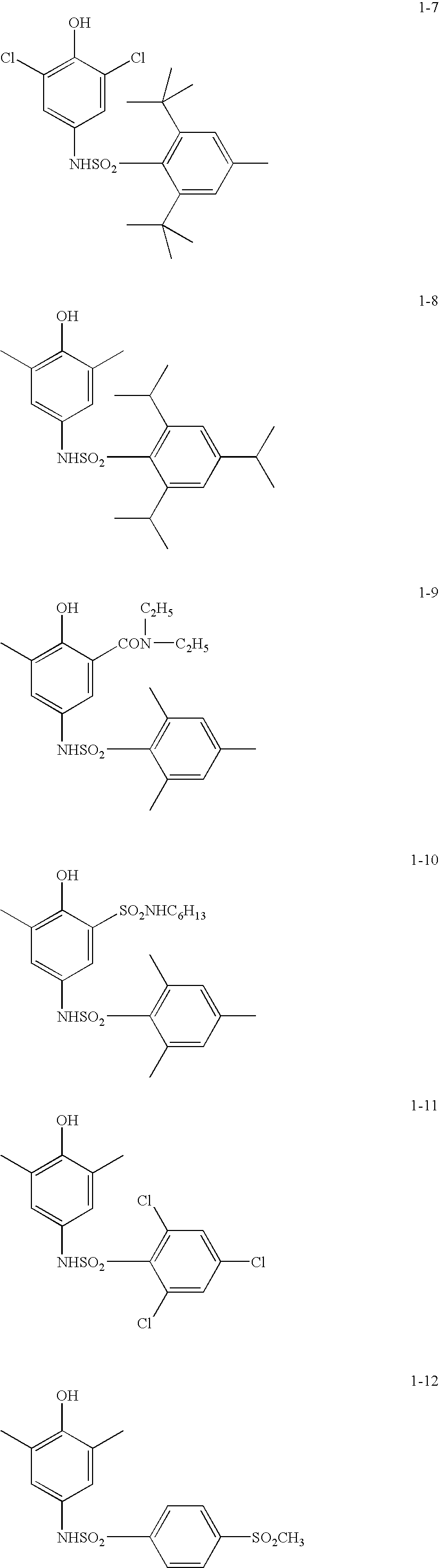

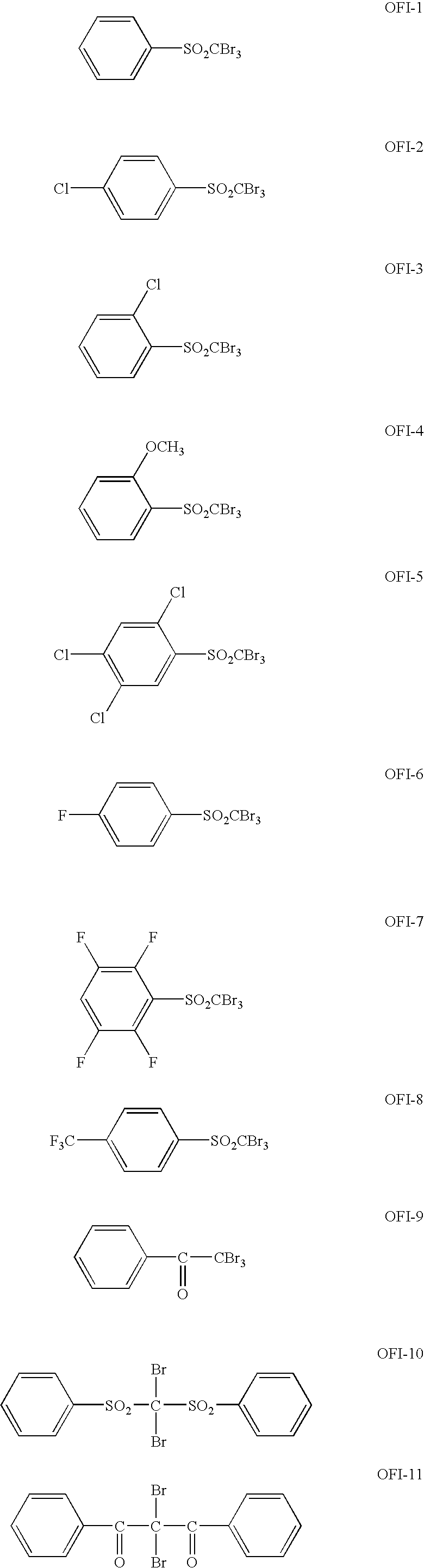

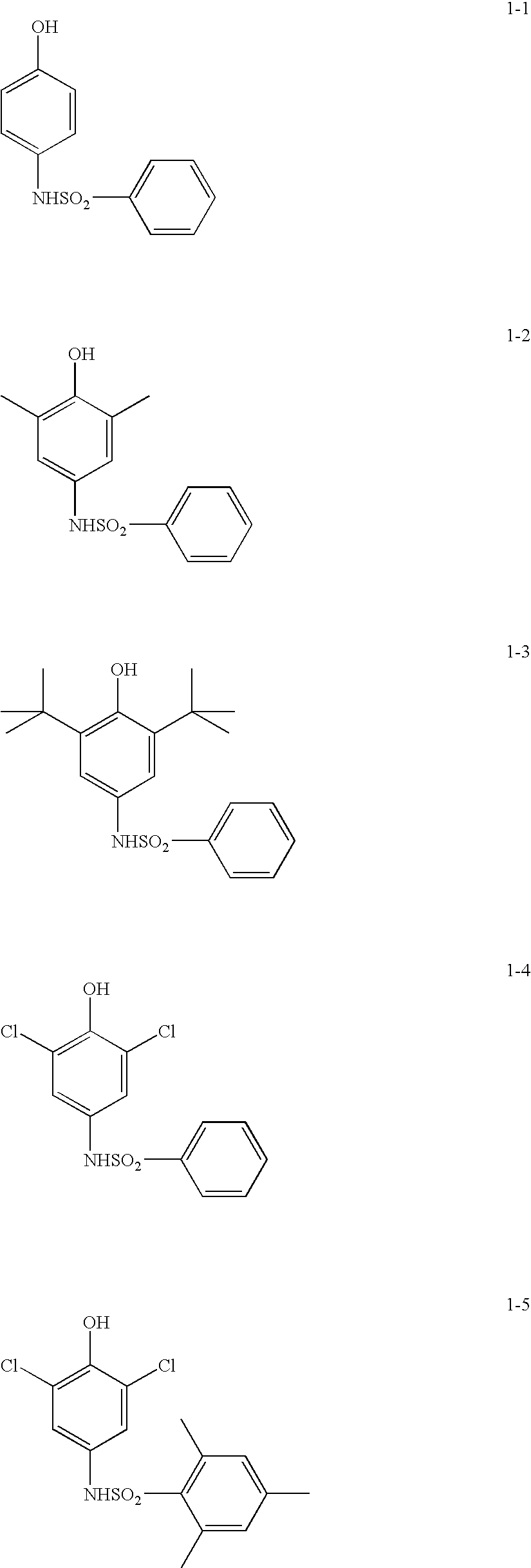

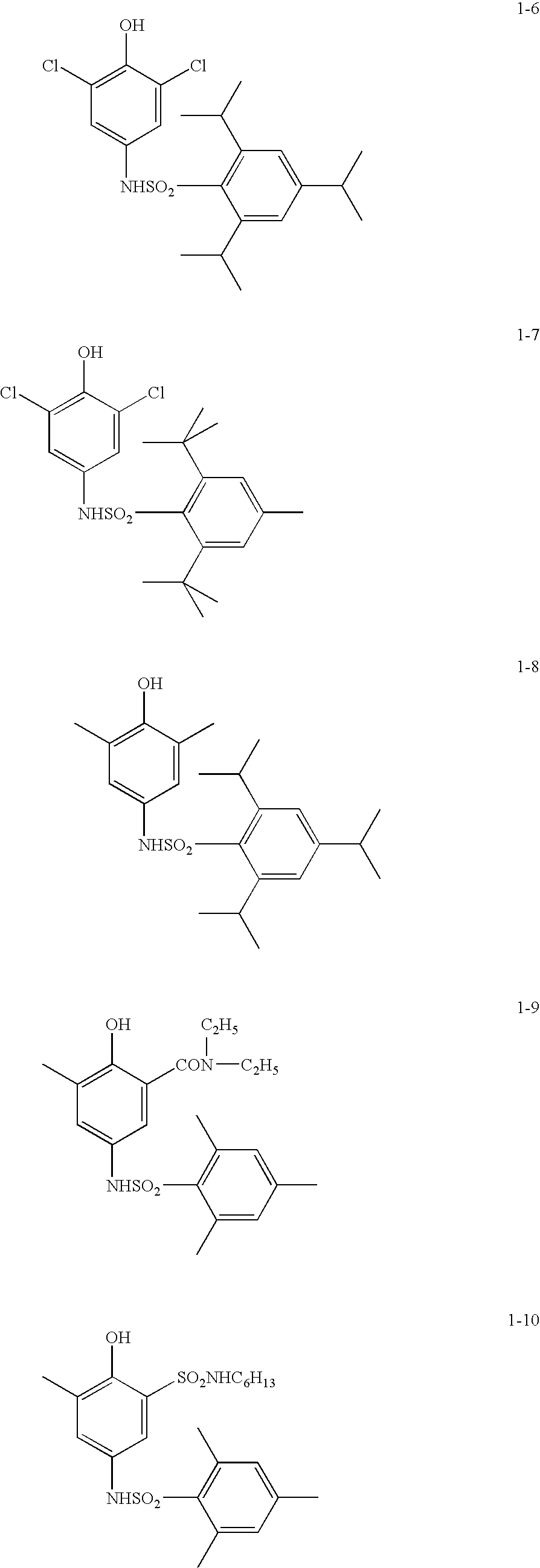

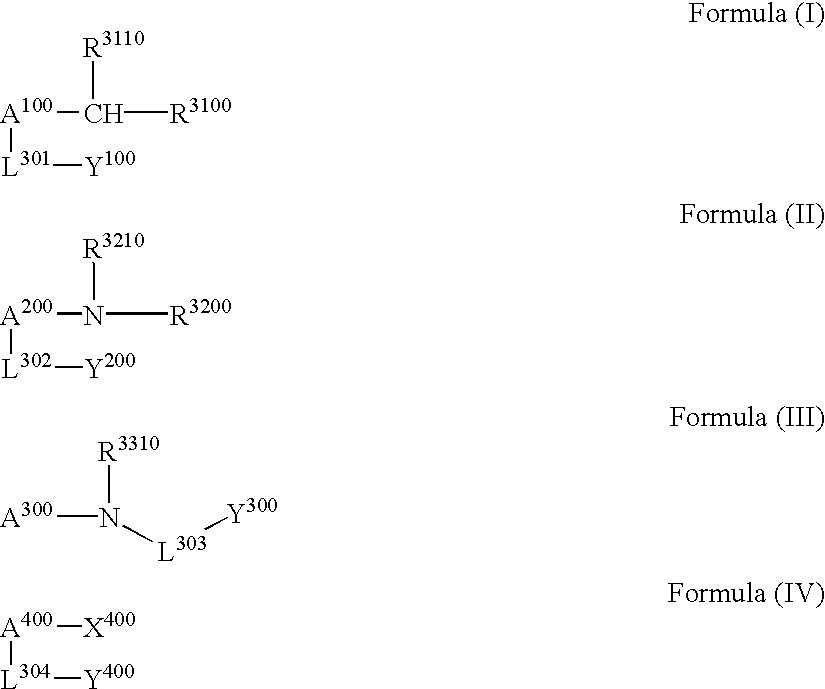

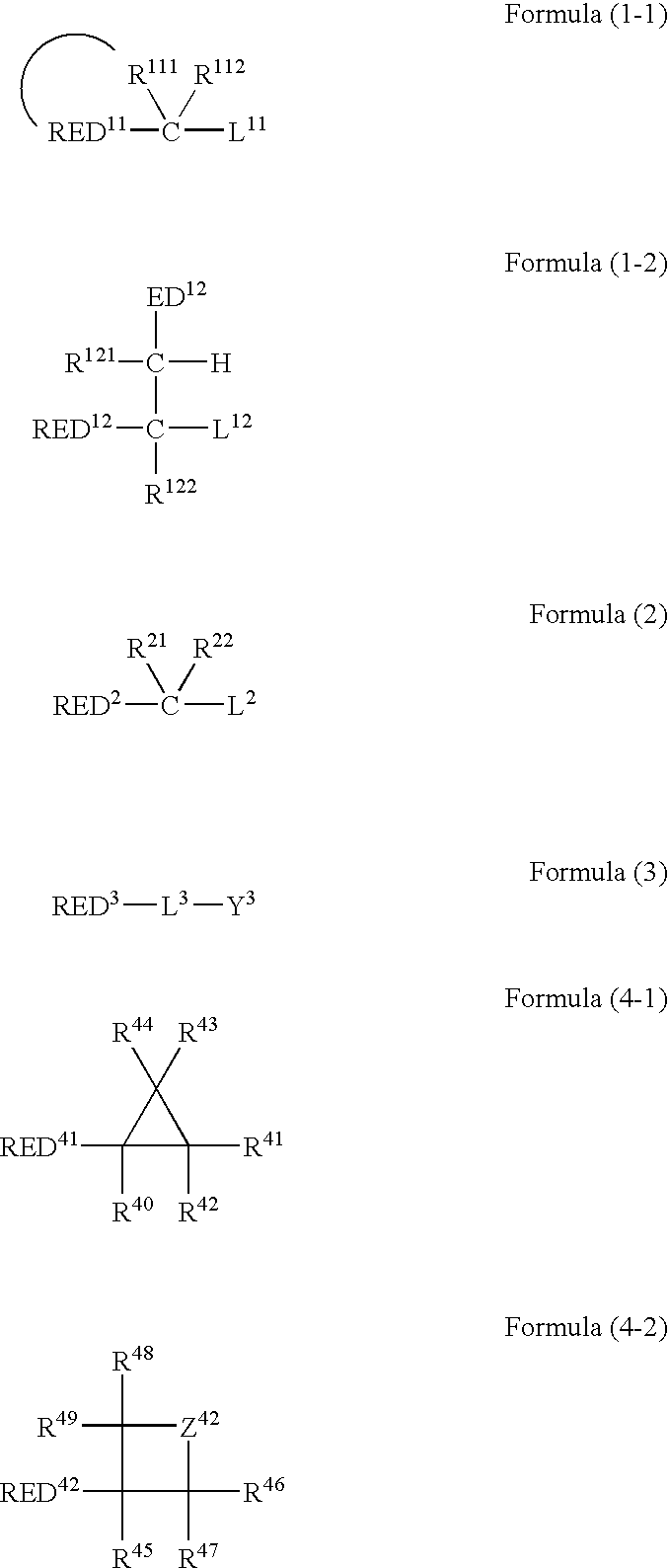

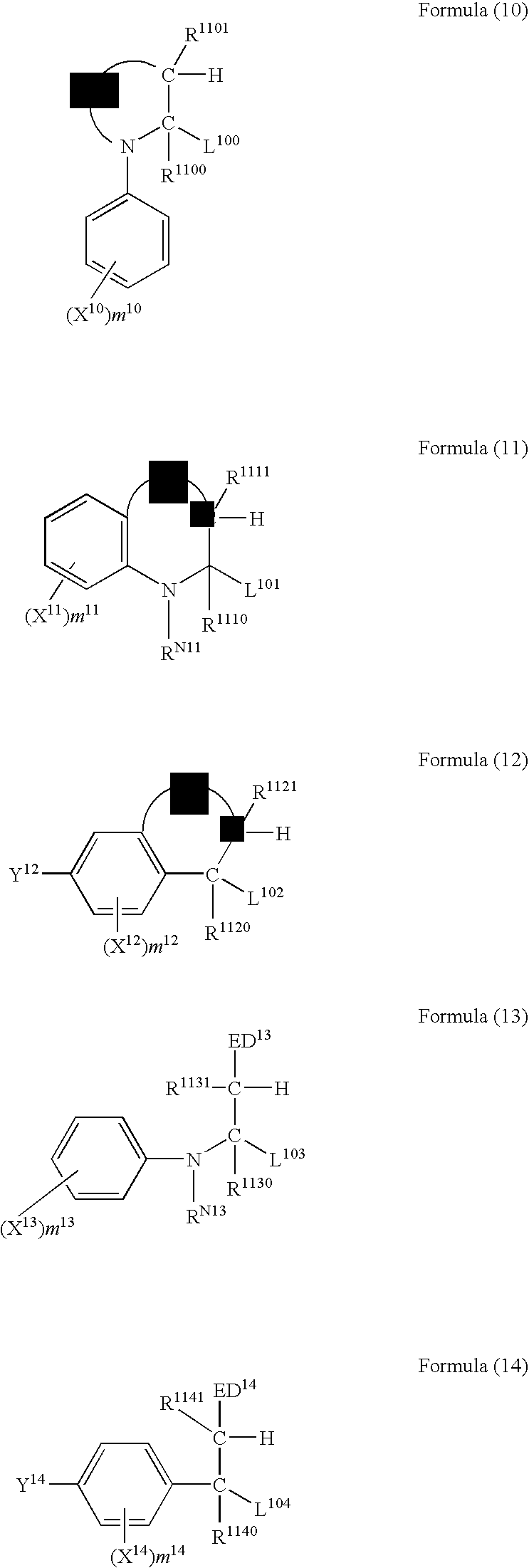

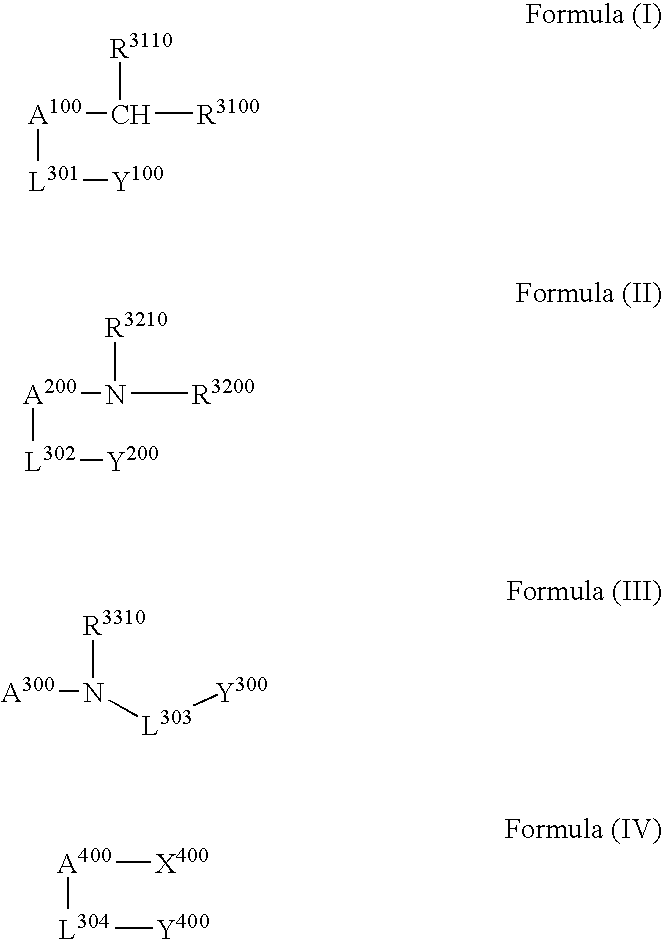

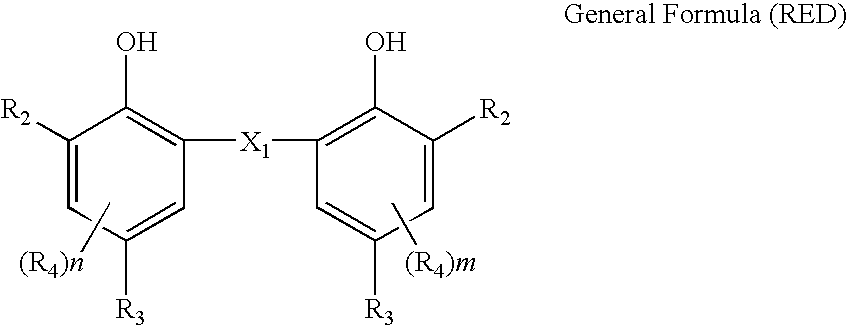

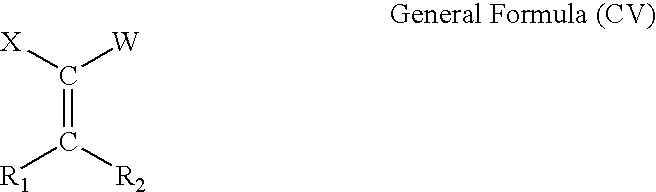

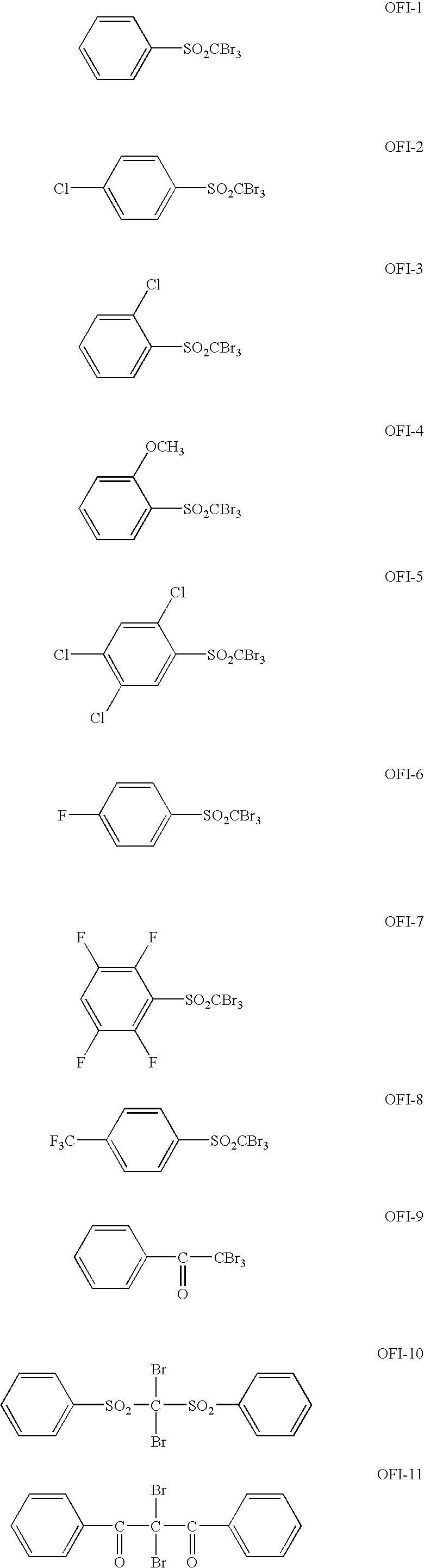

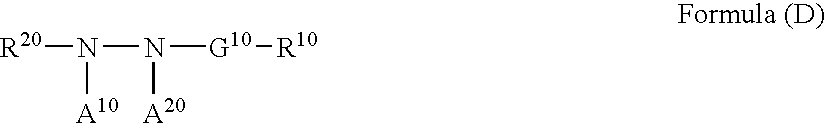

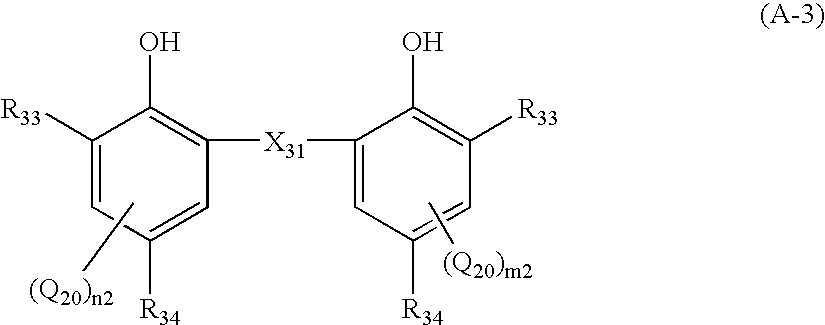

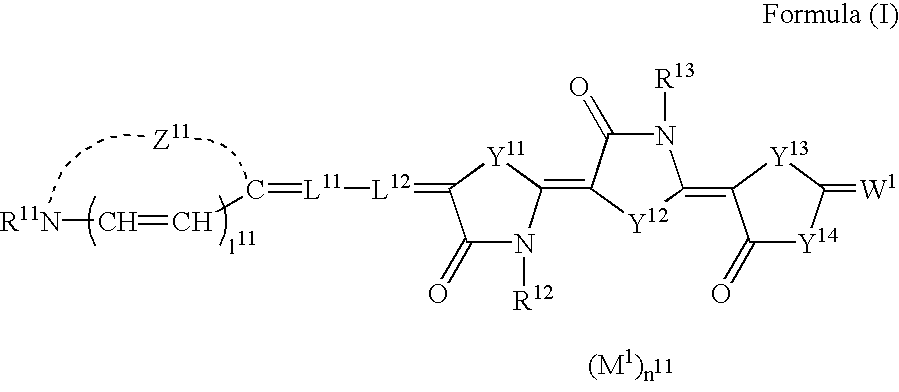

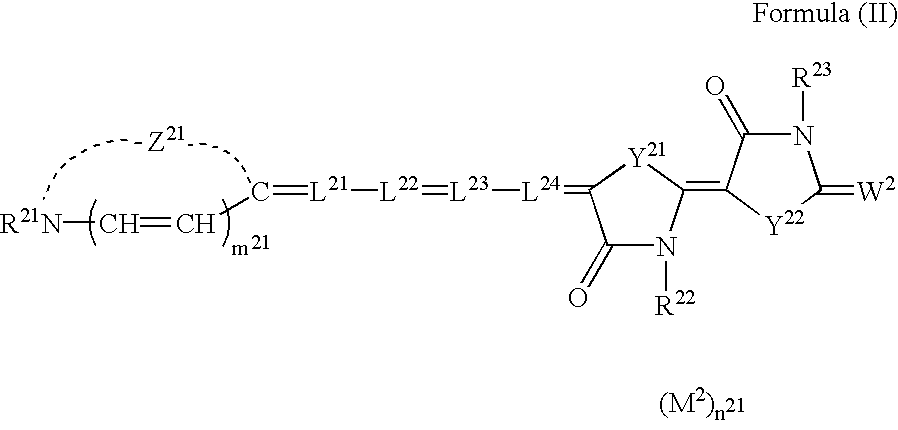

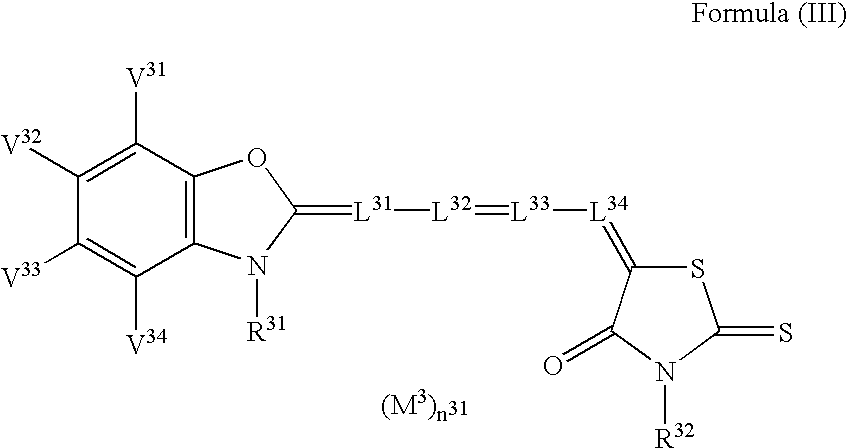

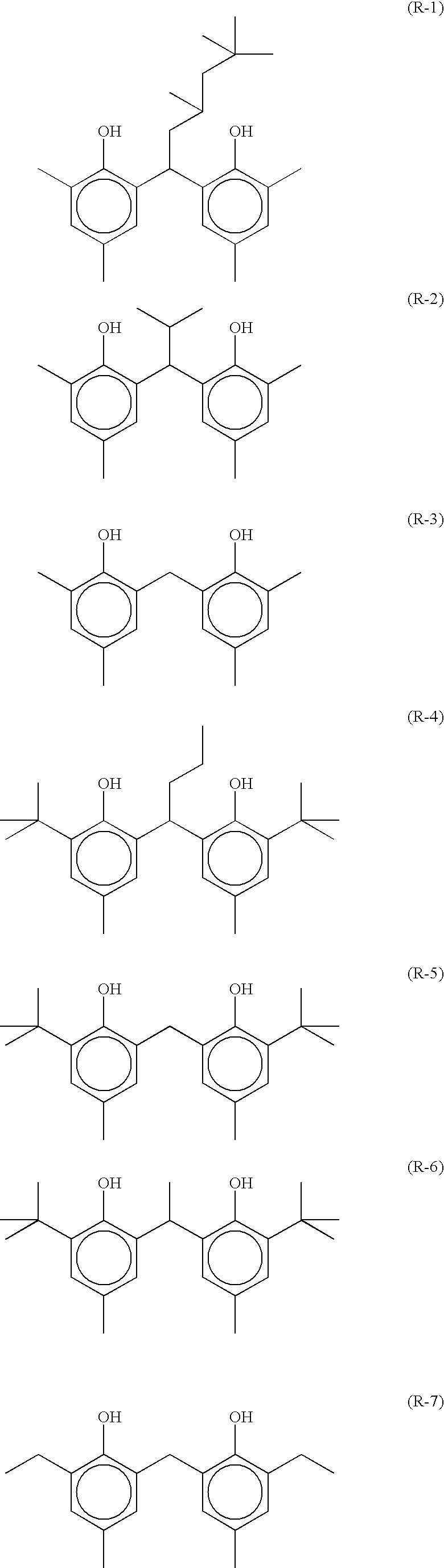

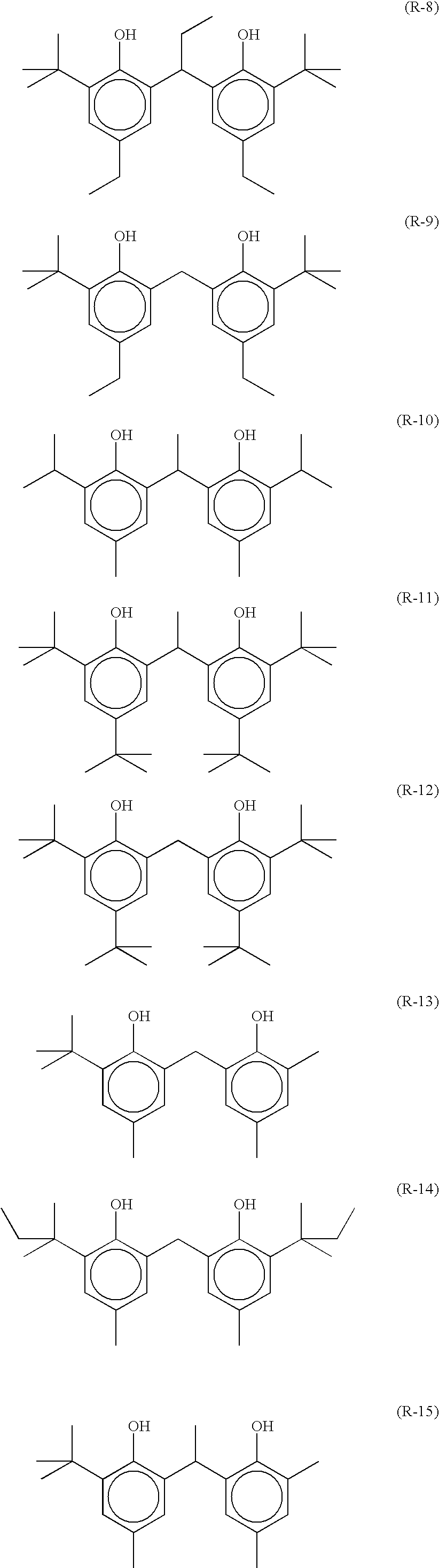

A photothermographic imaging material including a support; an image forming layer containing an organic silver salt, a photosensitive silver halide, a binder and a silver ion reducing agent, the image forming layer being provided on the support; and a cyan coloring leuco dye. The photosensitive silver halide contains silver halide grains having a mean particle size of 10 to 50 nm, and the silver ion reducing agent is a compound represented by the following Formula (A-3)

Owner:KONICA MINOLTA INC

Silver salt photothermographic dry imaging material, image recording method and image forming method for the same

InactiveUS7005251B2High sensitivityLow photographic fogDiffusion transfer processesX-ray/infra-red processesImage recordingLeuco dye

A silver salt photothermographic dry imaging material including non-photosensitive aliphatic carboxylic acid silver salts; a photosensitive emulsion containing photosensitive silver halide grains; a silver ion reducing agent; a binder; and a cyan coloring leuco dye. A percentage of the photosensitive silver halide grains having a mean particle size of 0.01 or more μm and 0.04 μm or less is 5% or more by mass and 50% or less by mass of total photosensitive silver halide grains by conversion into a silver amount.

Owner:KONICA MINOLTA INC

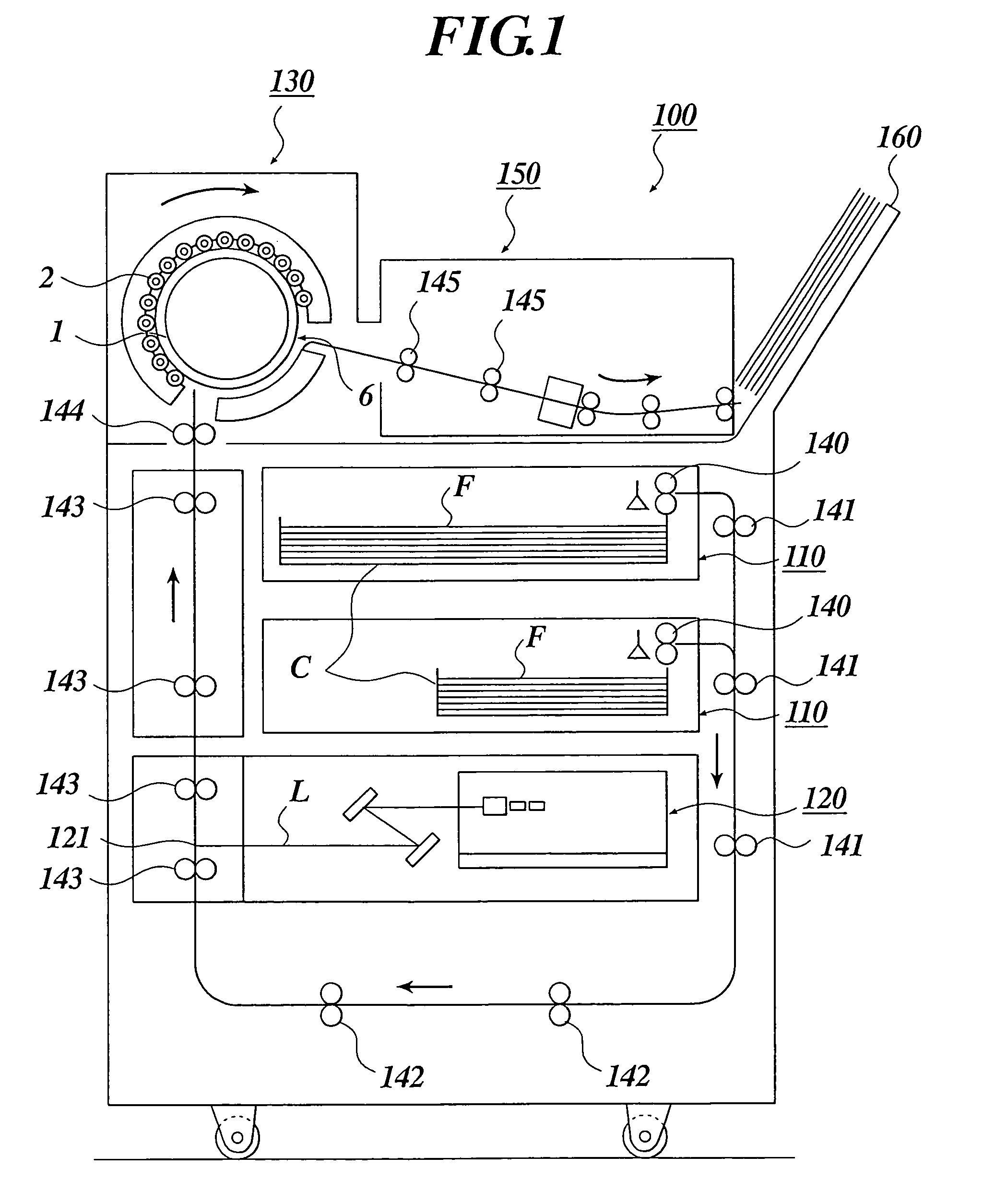

Image forming method for the photothermographic material

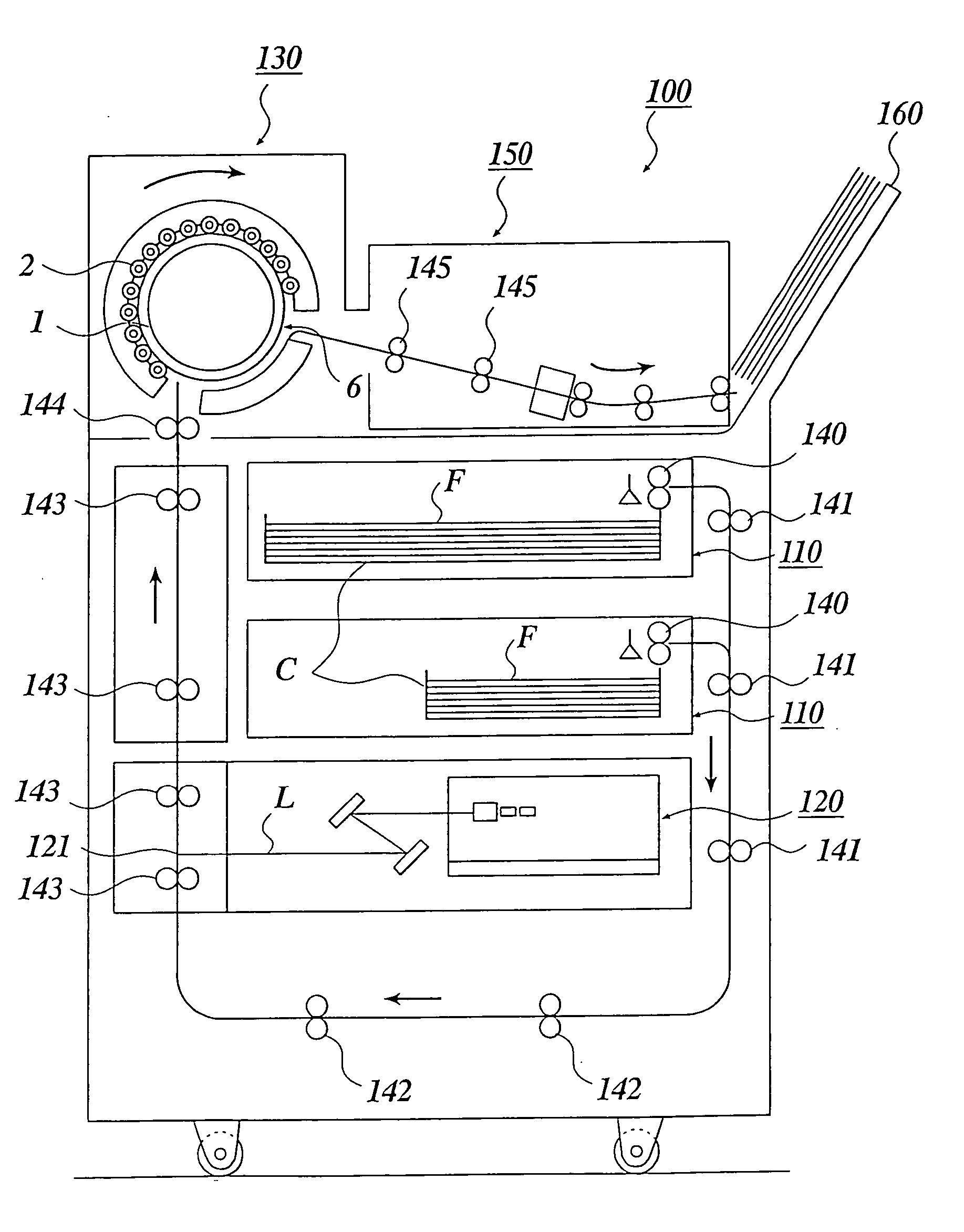

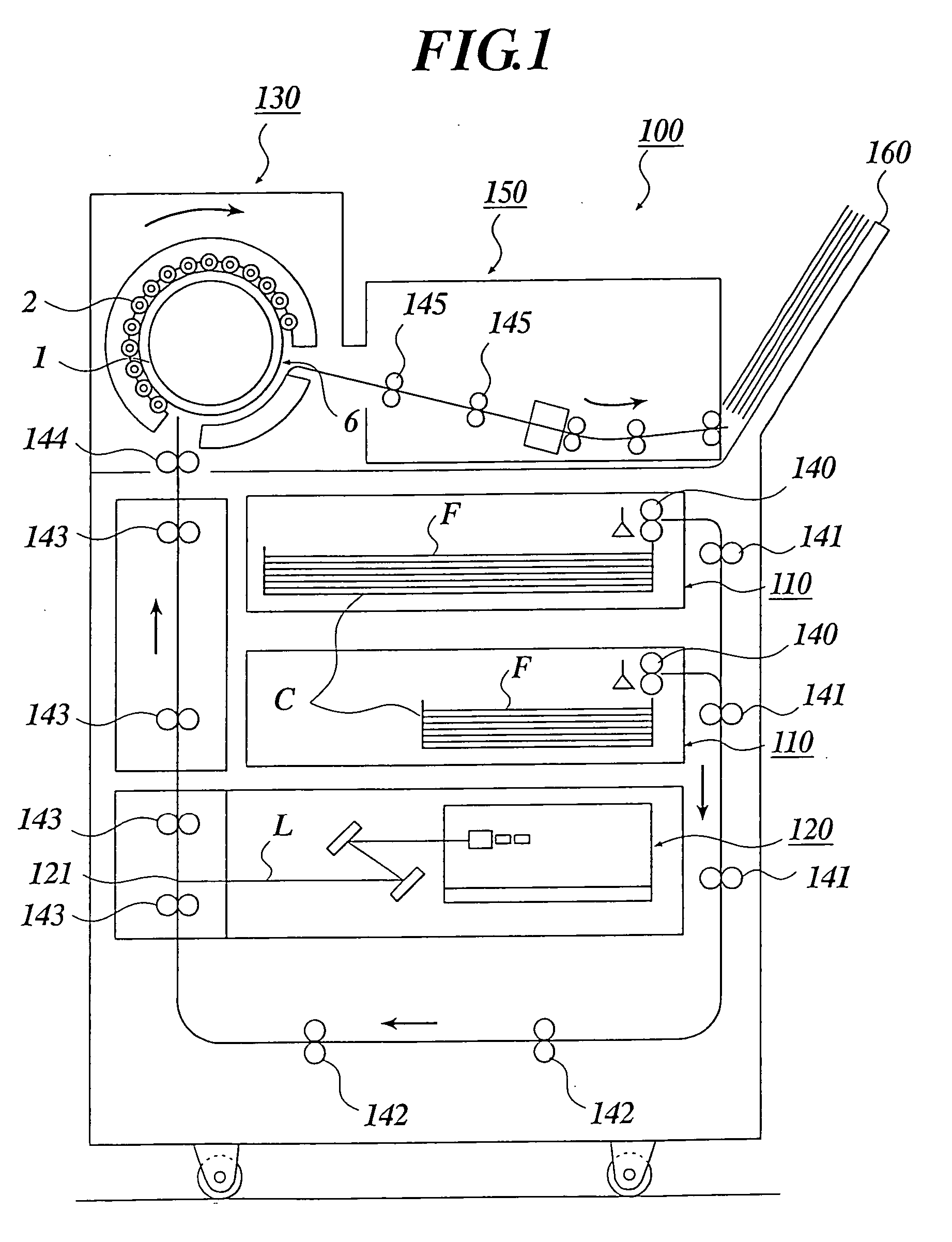

InactiveUS7462444B2Reducing silver ionsX-ray/infra-red processesMulticolor photographic processingSilver iodideImage recording

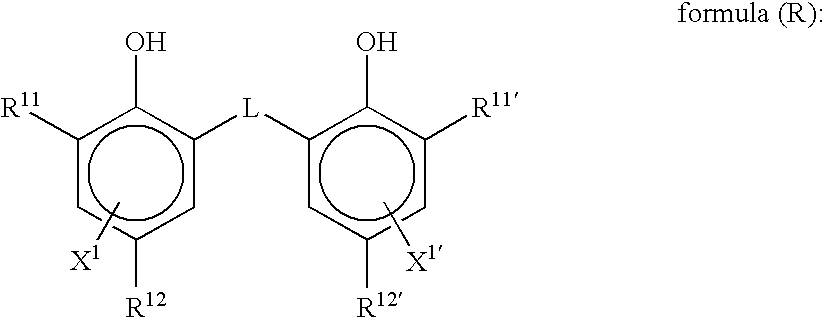

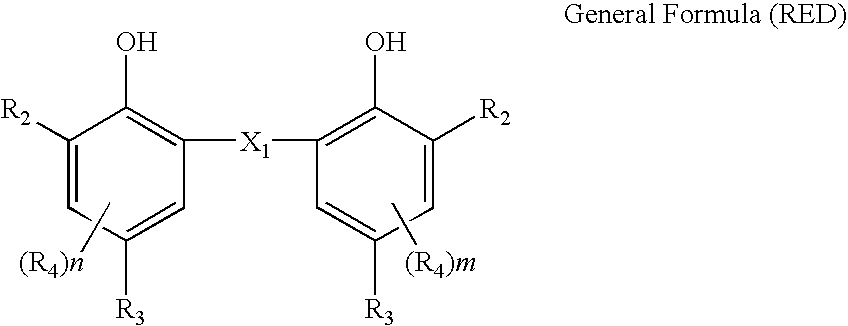

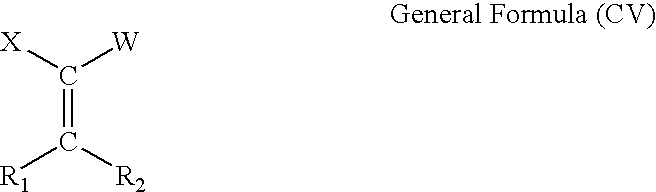

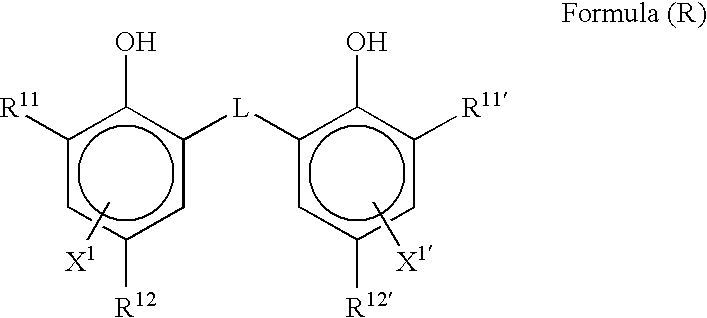

An image forming method comprising: imagewise exposing and thermal developing a photothermographic material using an image recording apparatus, wherein a part of the sheet is exposed and, in parallel with the exposure, development is started on a part of the sheet having been already exposed:wherein the photothermographic material comprises a reducing agent represented by formula (R), andwherein the photosensitive silver halide contains at least two preformed photosensitive silver halides having respective sensitivities different from each other for a light with the same exposure wavelength and a silver iodide content of the photosensitive silver halide is 40% by mole or more.

Owner:FUJIFILM HLDG CORP +1

Photothermographic material

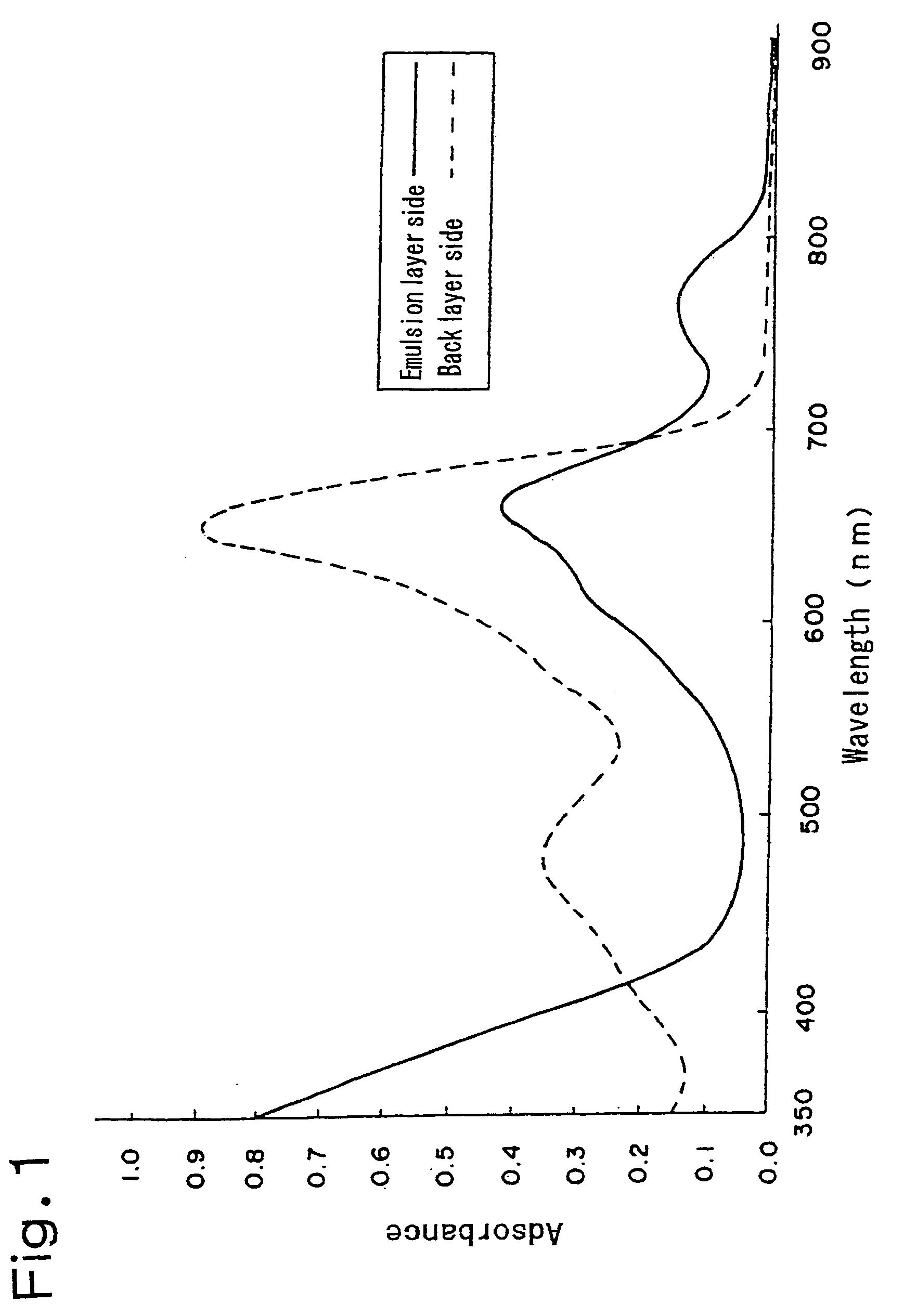

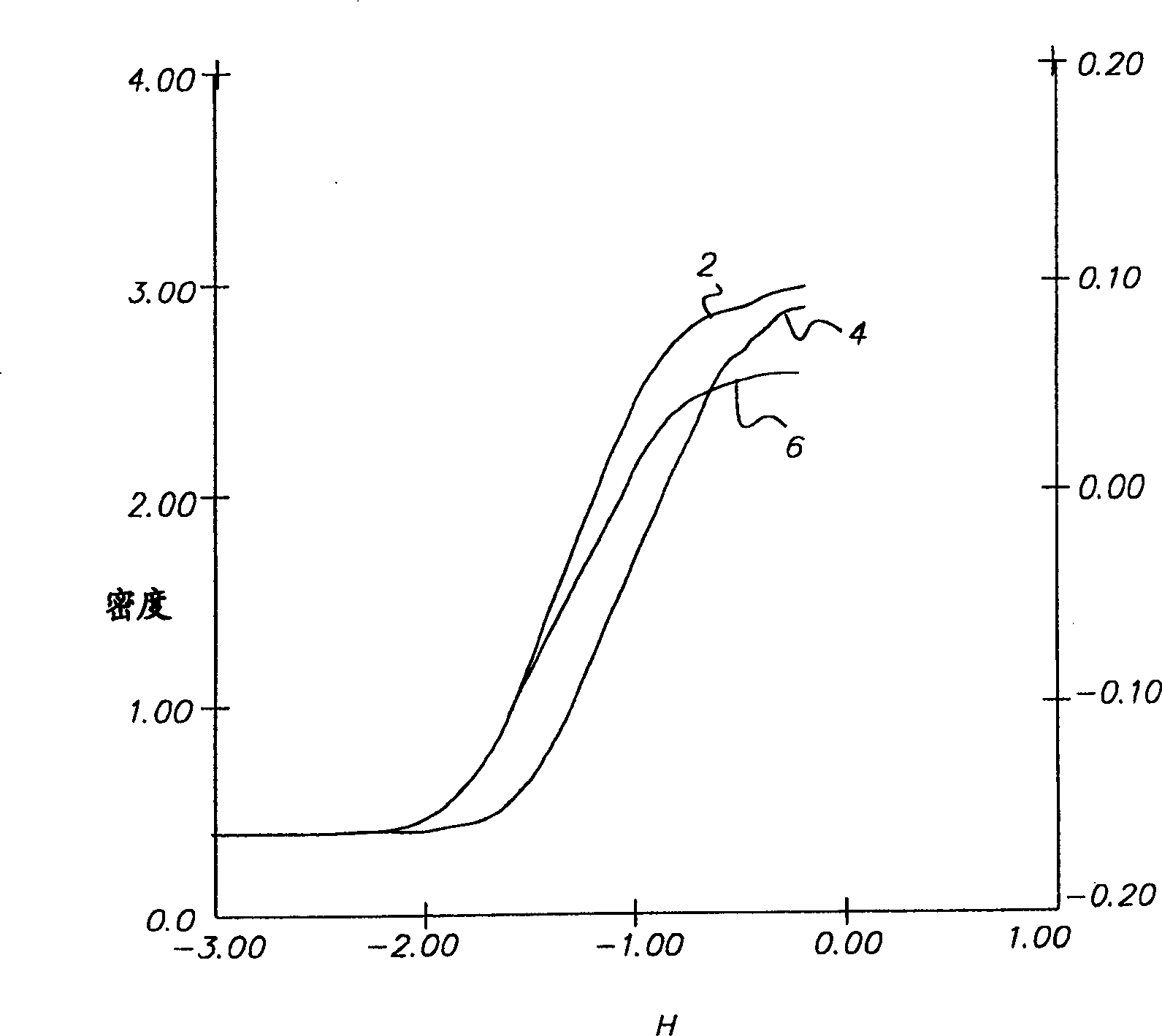

InactiveUS6297002B1Multicolor photographic processingSensitometric processesLight exposureMedical diagnosis

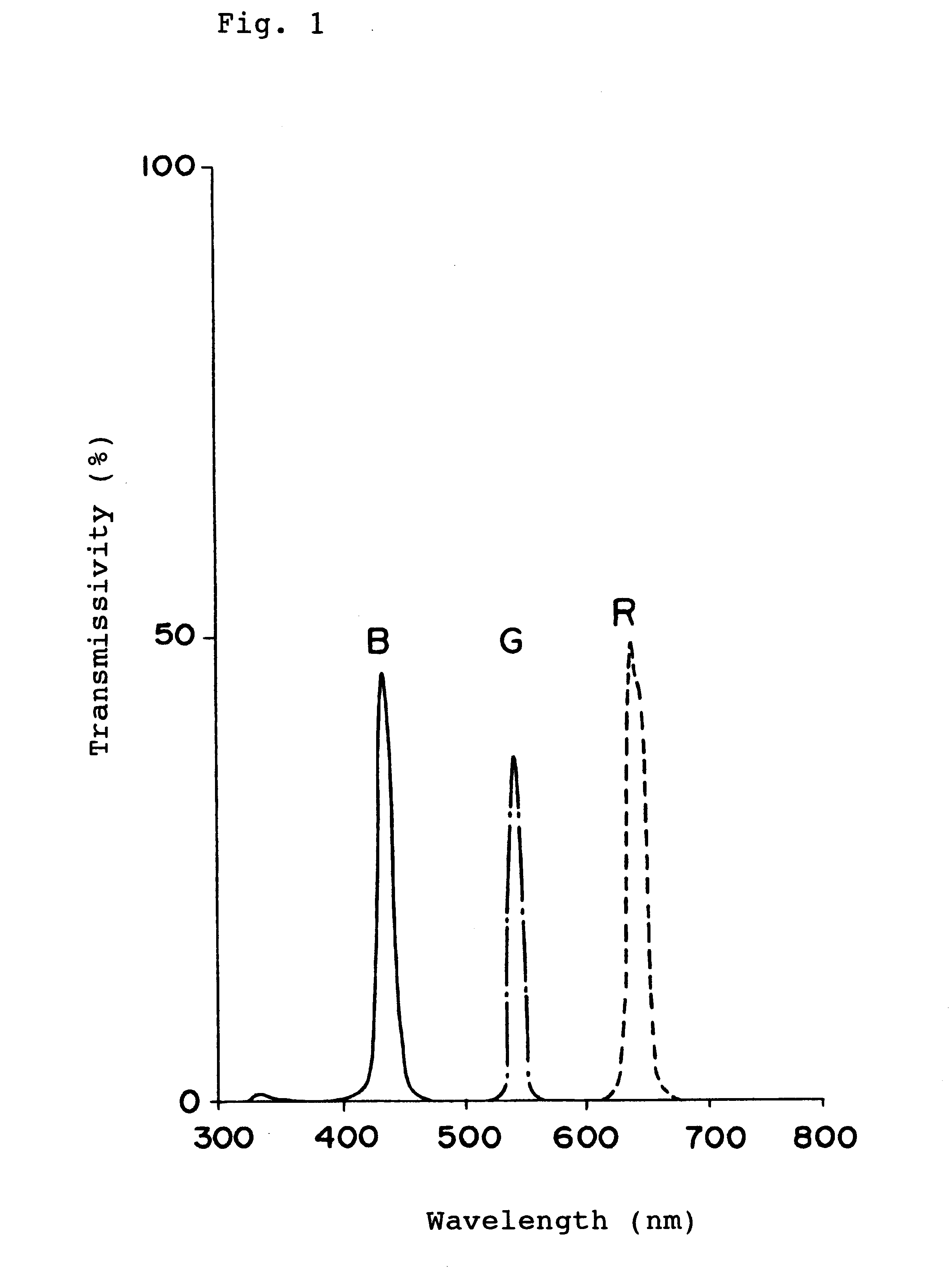

Provided is a photothermographic material containing on one side of a support a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent for silver ion and a binder, characterized in that an image obtainable after the light exposure and development satisfies a condition expressed as below:(where, DELTABG0.5 represents a value obtained by subtracting 0.5 from an optical density observed through a B filter of an image portion giving an optical density of 0.5 observed through a G filter, and DELTABG2.5 represents a value obtained by subtracting 2.5 from an optical density observed through a B filter of an image portion giving an optical density of 2.5 observed through a G filter.) The photothermographic material is suitable enough for medical diagnosis, and in particular for diagnosis of lung field.

Owner:FUJIFILM CORP

Method for preparing exposure curve for radiographic inspection

InactiveCN103279007AOperation saves time and effortMaterial analysis using wave/particle radiationSensitometric processesDosimeterEngineering

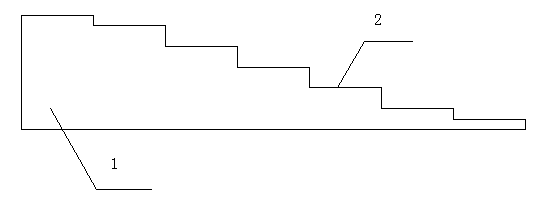

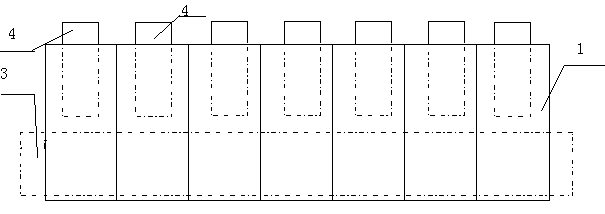

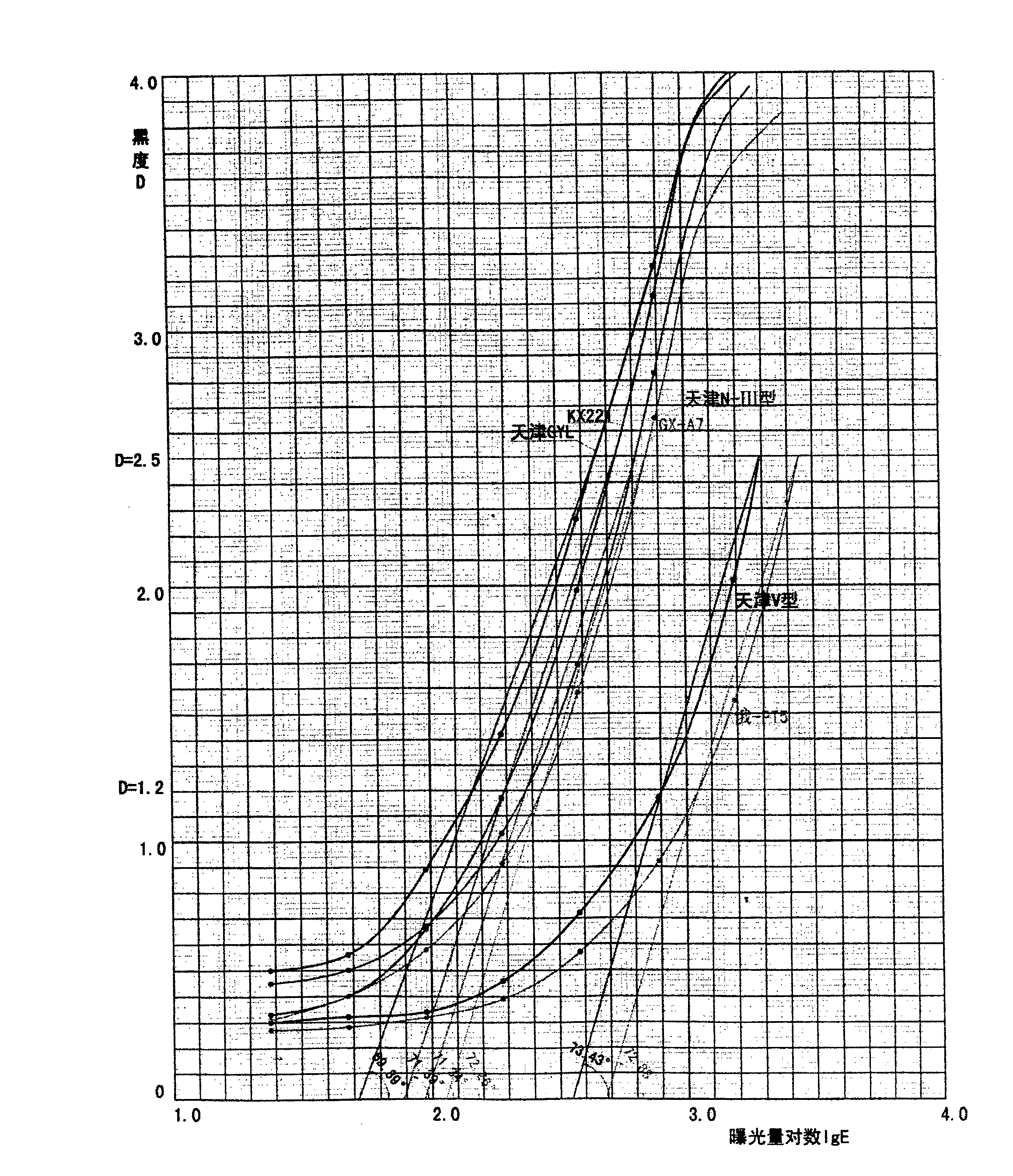

The invention discloses a method for preparing an exposure curve for radiographic inspection. The method comprises the following steps of (1) placing films and X-ray dosimeters on a stair test block; (2) exposing; (3) washing and drying the exposed films, utilizing a nigrometer to measure blackness values of negative films, reading accumulated doses corresponding to the blackness values to obtain a group of blackness values, and then finding an accumulated variable H corresponding to a standard blackness; (4) transilluminating a testing block to be detected with certain thickness under different transillumination conditions, stopping the transillumination when the accumulated variable is H, and recording light exposure at the time; (5) repeating the step (4) for multiple times to obtain a plurality of groups of light exposure under different transillumination conditions; (6) obtaining the exposure curve according to the thickness, the blackness values and the transillumination conditions of the transilluminated testing block to be detected with the certain thickness. According to the method for preparing the exposure curve for radiographic inspection, based on a relative relation between the blackness and the light exposure, the exposure curve can be obtained by only developing the films once, so that a plurality of films can be saved, and time-saving and labor-saving operation can be realized.

Owner:STATE GRID CORP OF CHINA +2

Silver halide photographic light-sensitive material

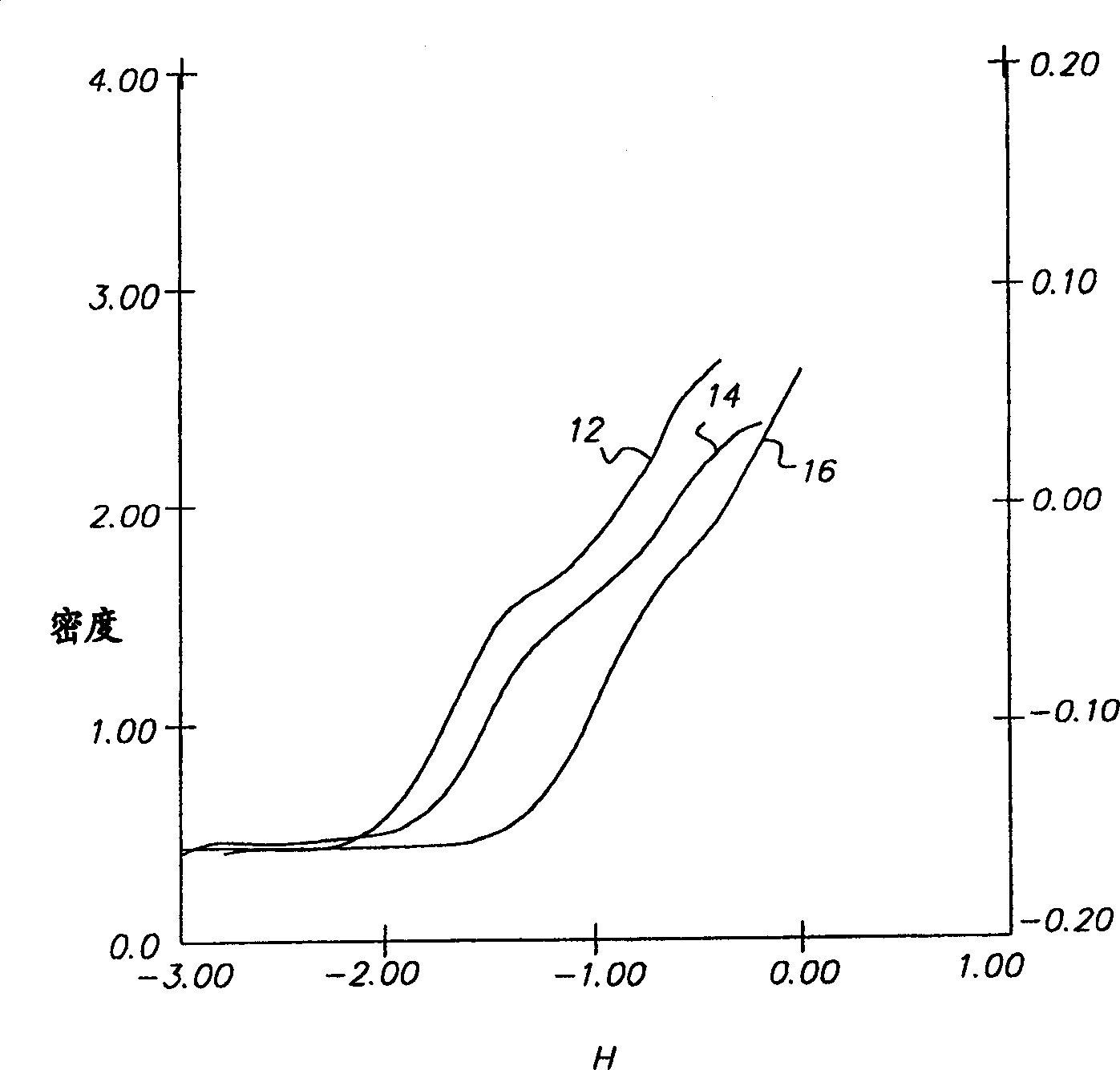

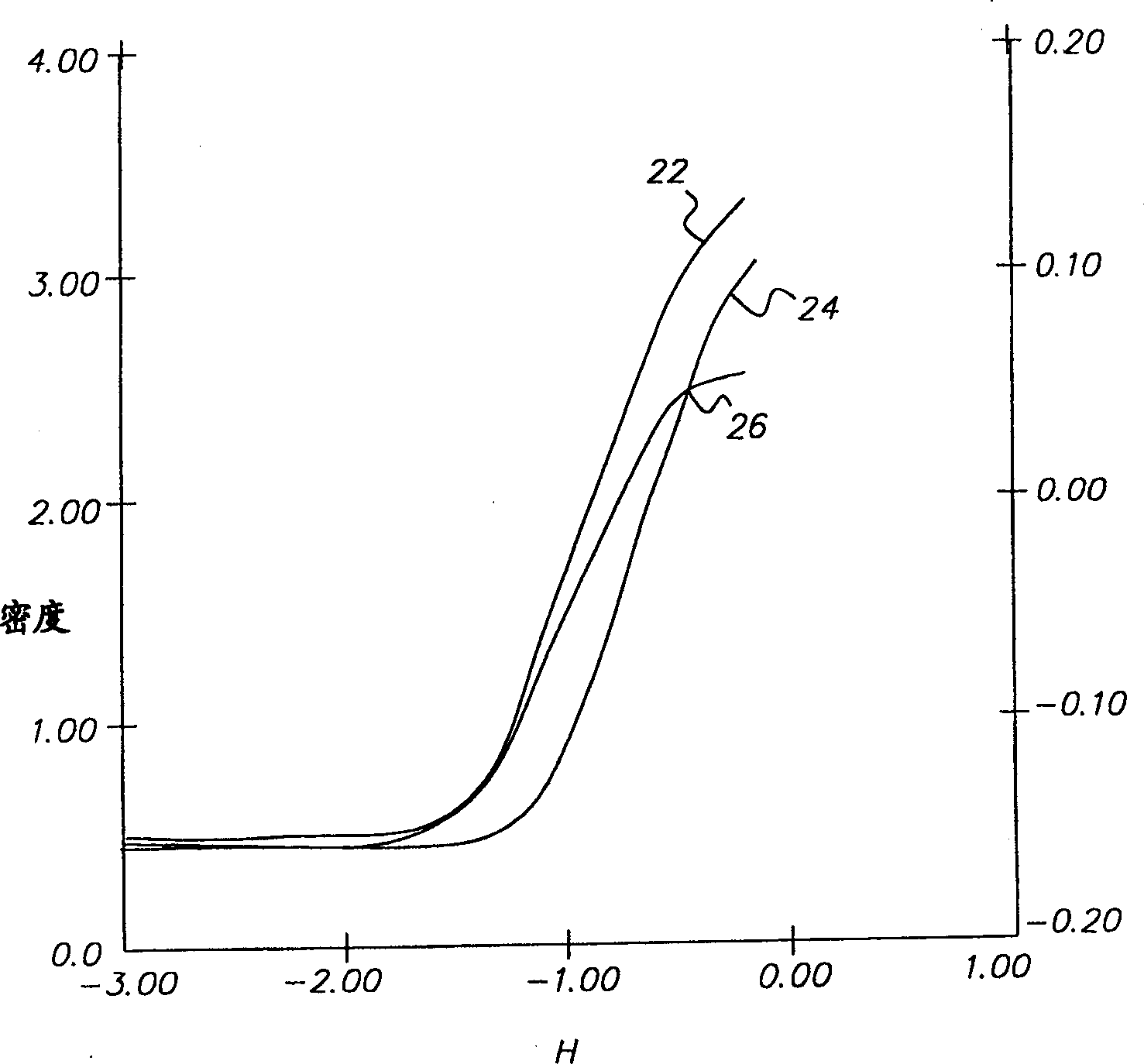

InactiveUS6645691B1Improve suppression propertiesSensitometric processesPhotosensitive material auxillary/base layersOrthogonal coordinatesLight exposure

Disclosed is a silver halide photographic light-sensitive material in the shape of a light-shielded light-sensitive material roll, which has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 5.0 or more for the optical density range of 0.3-3.0. There is provided a silver halide photographic light-sensitive material in the shape of a light-shielded light-sensitive material roll suffering from little influence on photographic properties after long term storage.

Owner:FUJIFILM CORP

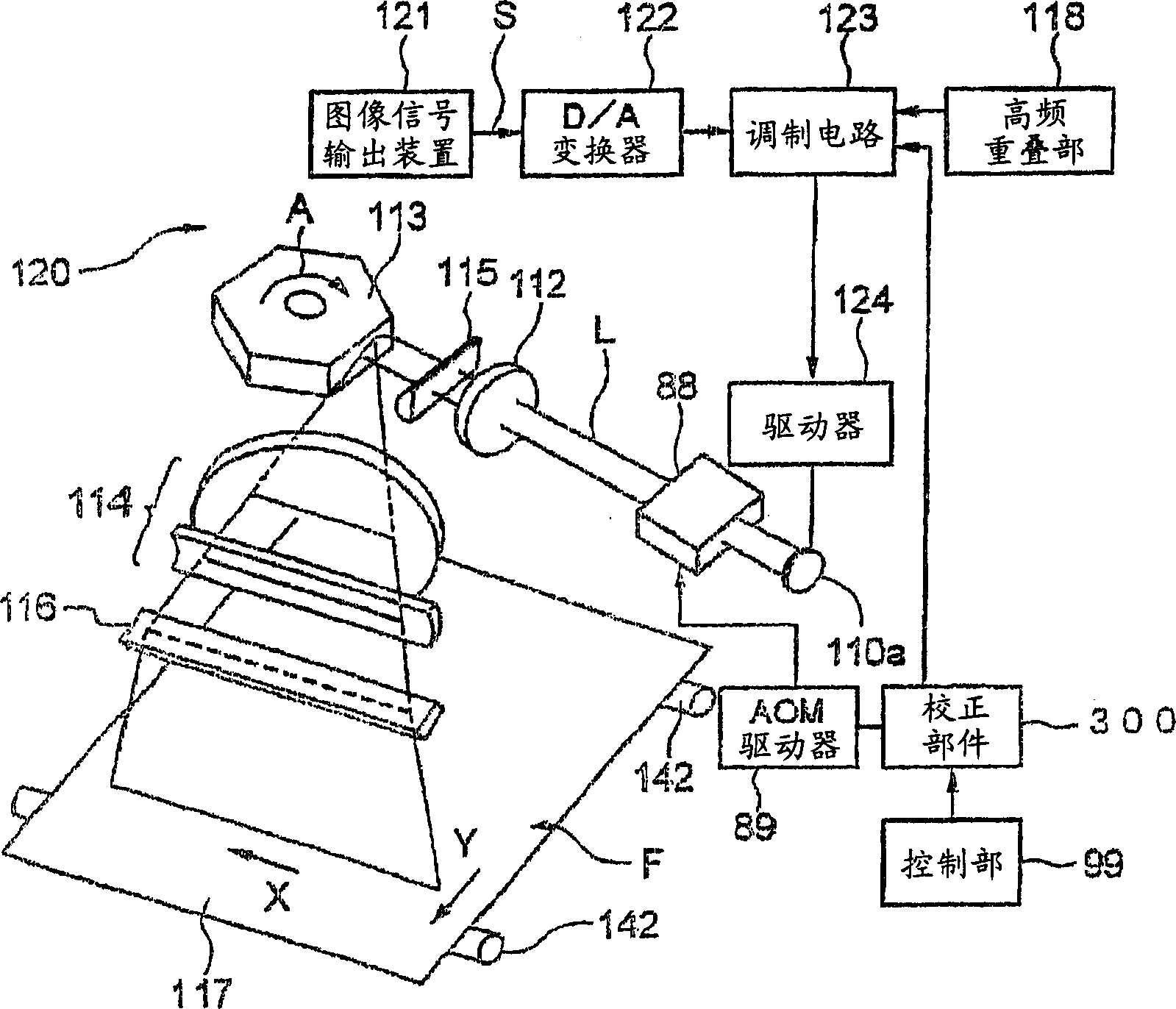

Image processor, image processing method and programm

An image processing apparatus, comprising: an exposing device for exposing an image forming material so as to form a latent image on the image forming material based on image data; a developing device for developing and visualizing the latent image on the exposed image forming material so as to form an image; a measuring device for measuring the image density of the image on the developed image forming material; a calibrating device for forming a table to define a relation between an image signal and image density on the basis of plural different test image data and measured-image densities thereof; a storing device for storing a characteristic change model indicating a characteristic change of at least one of the exposing device and the developing device with time; a difference calculating device to calculate a density difference on the basis of the characteristic change model between the time of forming the table and the time of forming an image based on image signal of diagnostic image data; and a correcting device for correcting the table on the basis of the density difference calculated by the difference calculating device.

Owner:KONICA MINOLTA INC

Silver halide photosensitive material and process of producing black and white image using the same

InactiveUS20110070548A1High resolutionDeterioration of image quality is suppressedPhoto-taking processesMulticolor photographic processingSilver halideMaterials science

Disclosed is a silver halide photographic photosensitive material which includes a support and at least one silver halide photosensitive layer on the support, wherein the average equivalent sphere diameter of the silver halide of the silver halide photosensitive layer is 0.30 μm or less, the silver halide photosensitive layer includes four or more kinds of silver halide grains having mutually different average equivalent sphere diameters, and the thickness between a surface of the support at a side at which the silver halide photosensitive layer is provided and a surface of the silver halide photosensitive layer at a side opposite to the support is 10 μm or less.

Owner:FUJIFILM CORP

Black and white photothermographic material

InactiveUS20070196779A1Photosensitive materialsMulticolor photographic processingHeat sensitiveOptical density

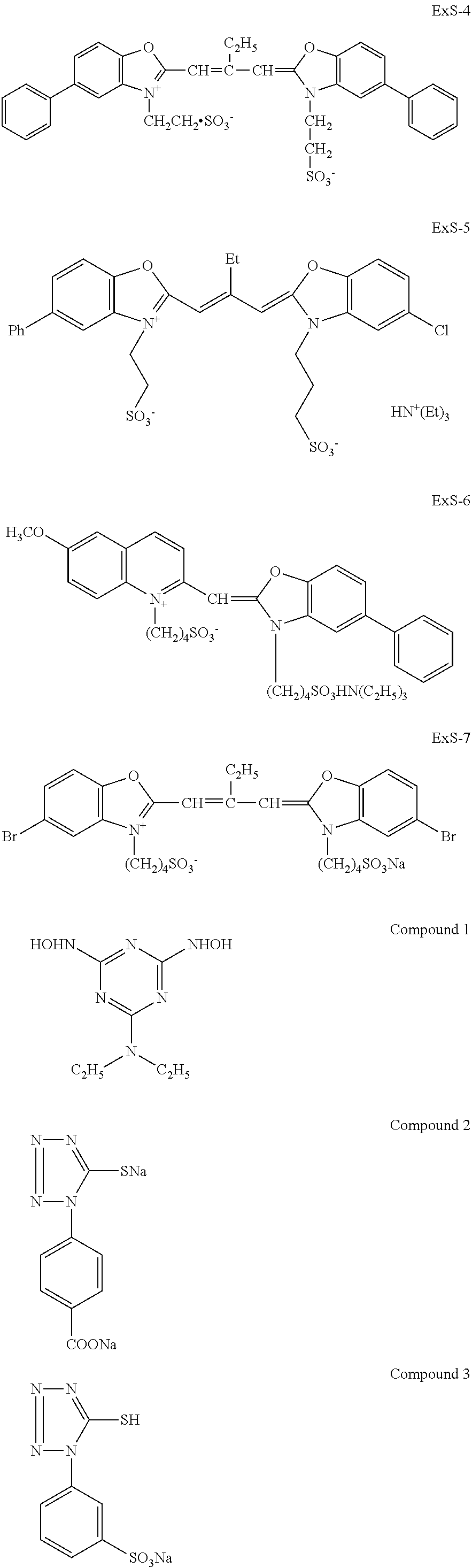

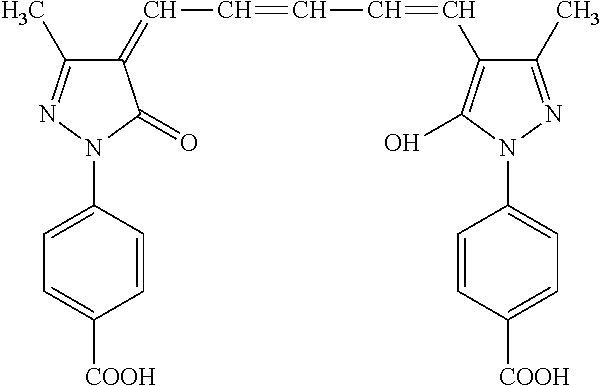

The present invention provides a black and white photothermographic material including, on at least one side of a support, at least a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent for silver ions, a color developing agent, and a coupler which reacts with an oxidation product of the color developing agent to form a dye, wherein a total amount of ammonia included on one side of the support having thereon the photosensitive silver halide is from 5 mg / m2 to 25 mg / m2, and an optical density of an image formed by imagewise exposing and thermally developing the black and white photothermographic material satisfies the following equation (A):0.02<Dc<D / 4 Equation (A)wherein D represents an optical density in a range of from 1 to 2, and Dc represents an optical density obtained by the dye in the optical density of the image.

Owner:FUJIFILM CORP

Black and white photothermographic material

InactiveUS20070196778A1Photosensitive materialsMulticolor photographic processingVolumetric Mass DensityHeat sensitive

The present invention provides a black and white photothermographic material having, on at least one side of a support, an image forming layer including at least a photosensitive silver halide and a non-photosensitive organic silver salt, and a non-photosensitive layer including at least a coupler, wherein at least one of the image forming layer and the non-photosensitive layer includes a color developing agent; a grain density of the photosensitive silver halide in the image forming layer is from 20 grains / μm3 to 103 grains / μm3; and an optical density of an image formed by imagewise exposing and thermally developing the black and white photothermographic material satisfies the following equation (A):0.02<Dc<D / 4 Equation (A)wherein D represents a value of an optical density in a range of from 1.0 to 2.0; and Dc represents an optical density obtained by the dye in the optical density of the image.

Owner:FUJIFILM CORP

Silver salt photothermographic dry imaging material

InactiveUS7175978B2Good storage stabilityIncrease speedX-ray/infra-red processesMulticolor photographic processingSilver ionSilver particles

A photothermographic imaging material packed in a packaging material, the imaging material including a support having thereon light-insensitive organic silver salt grains, photosensitive silver halide grains, a reducing agent for silver ions and a binder, wherein the packaging material has a water permeability of not less than 5.0 g / m2 measured at a temperature of 40° C. with a relative humidity of 90% for 24 hours; and the imaging material has a first photographic speed and a second photographic speed and the second photographic speed is not more than 1 / 10 of the first photographic speed, the measuring methods of the first and the second photographic speeds being defined in the specification.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Silver halide photographic light-sensitive material

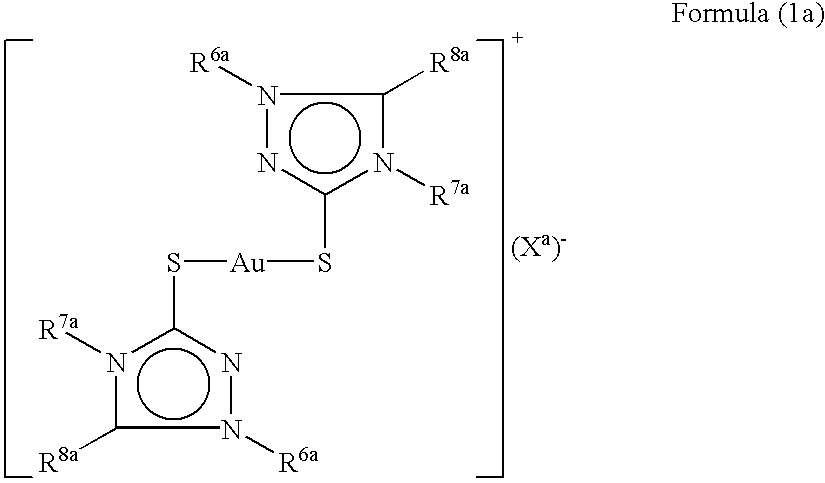

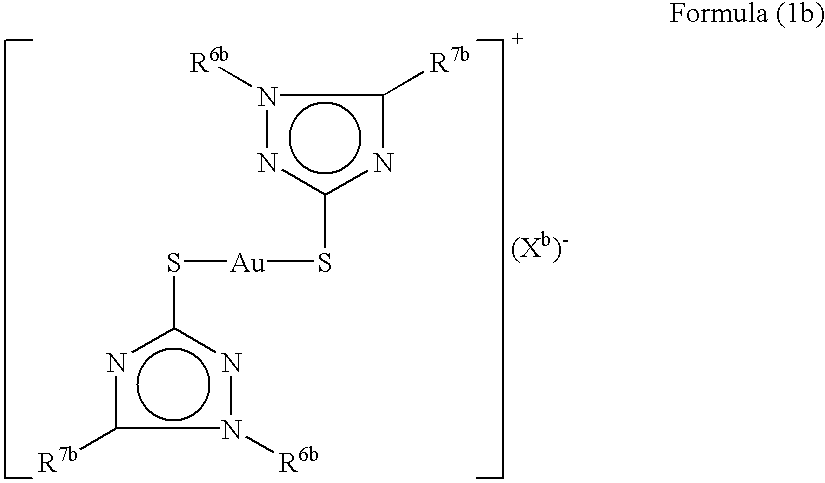

InactiveUS20030211431A1Multicolor photographic processingSensitometric processesOrganogold CompoundsOrthogonal coordinates

Disclosed is a silver halide photographic light-sensitive material comprising at least one silver halide emulsion layer on a support, which contains at least one organic gold compound and has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 5.0 or more for the optical density range of 0.3-3.0. This silver halide photographic light-sensitive material provides high contrast and high sensitivity.

Owner:FUJIFILM HLDG CORP

Black and white photothermographic material

InactiveUS20070196777A1Multicolor photographic processingSensitometric processesImage formationHeat sensitive

The present invention provides a black and white photothermographic material having, a first image forming layer including at least a photosensitive silver halide, a non-photosensitive organic silver salt, and a reducing agent for silver ions, wherein the black and white photothermographic material further has a second image forming layer including at least a coupler, and at least one of the first image forming layer and the second image forming layer includes a color developing agent. A black and white photothermographic material which exhibits high sensitivity, excellent image tone, and excellent storage stability is provided.

Owner:FUJIFILM CORP

Silver halide photographic light sensitive material

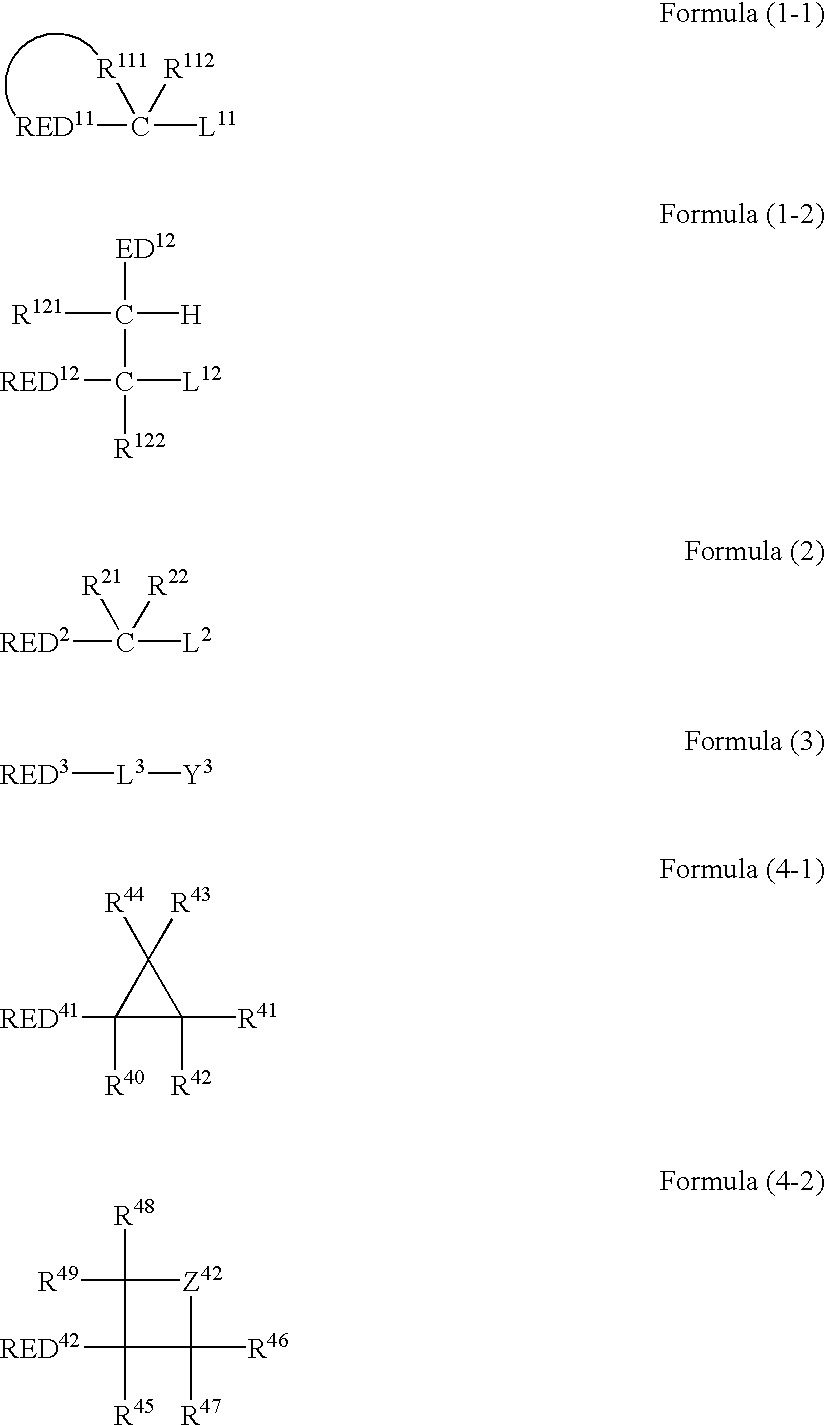

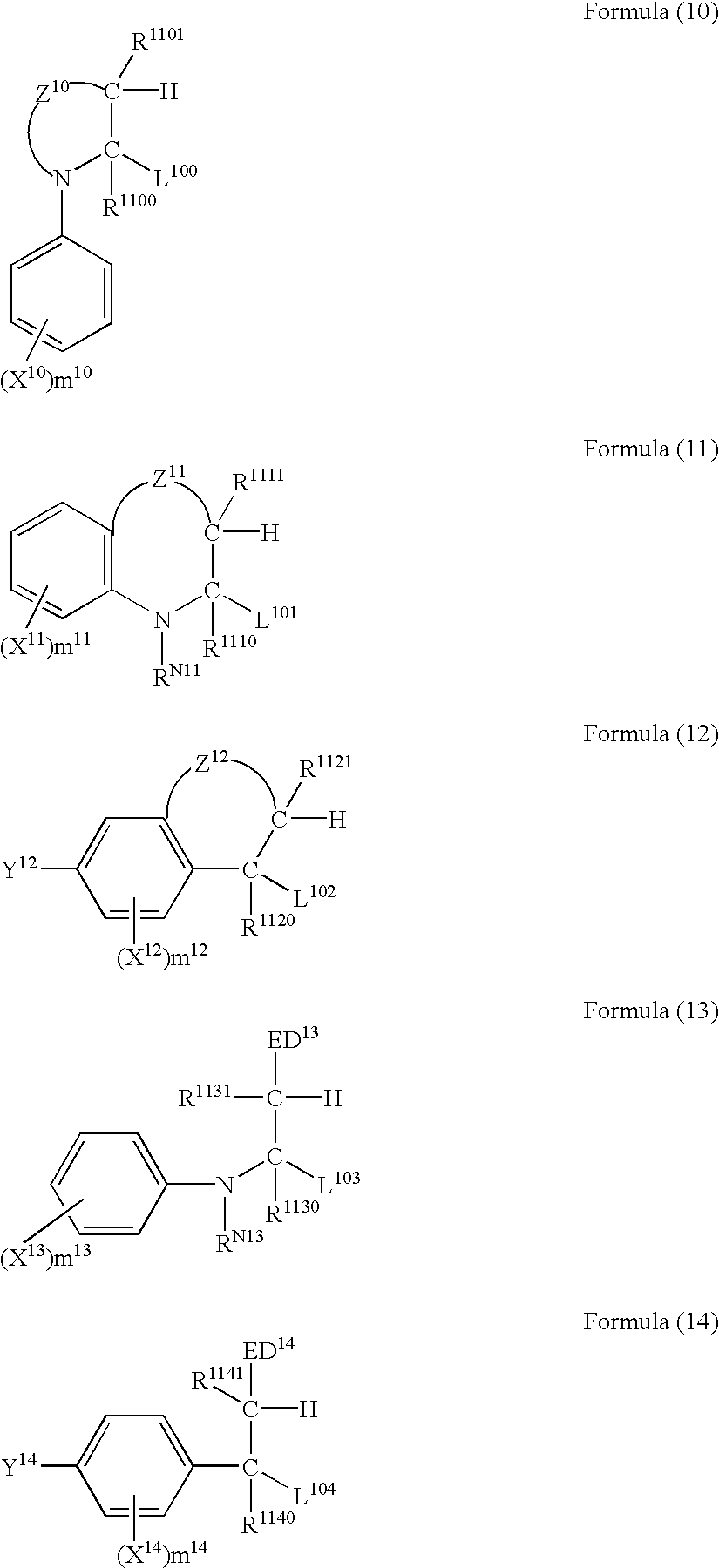

InactiveUS20030232272A1Radiation applicationsPhotoprinting processesOrthogonal coordinatesBond cleavage

Disclosed is a silver halide photographic light-sensitive material comprising at least one silver halide emulsion layer on a support, which contains a compound of which one-electron oxidized derivative produced by one electron oxidation of the compound is capable of releasing two or more electrons with a bond cleavage and has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 5.0 or more for the optical density range of 0.3-3.0. This silver halide photographic light-sensitive material shows high contrast and high sensitivity.

Owner:FUJIFILM CORP

Silver halide photographic light sensitive material

Disclosed is a silver halide photographic light-sensitive material comprising at least one silver halide emulsion layer on a support, which contains a compound of which one-electron oxidized derivative produced by one electron oxidation of the compound is capable of releasing two or more electrons with a bond cleavage and has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 5.0 or more for the optical density range of 0.3-3.0. This silver halide photographic light-sensitive material shows high contrast and high sensitivity.

Owner:FUJIFILM CORP

Silver salt photothermographic dry imaging material

InactiveUS20050158676A1Good storage stabilityIncrease speedX-ray/infra-red processesMulticolor photographic processingHeat sensitivePack material

A photothermographic imaging material packed in a packaging material, the imaging material including a support having thereon light-insensitive organic silver salt grains, photosensitive silver halide grains, a reducing agent for silver ions and a binder, wherein the packaging material has a water permeability of not less than 5.0 g / m2 measured at a temperature of 40° C. with a relative humidity of 90% for 24 hours; and the imaging material has a first photographic speed and a second photographic speed and the second photographic speed is not more than 1 / 10 of the first photographic speed, the measuring methods of the first and the second photographic speeds being defined inn the specification.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Grey card for controlling exposure and white balance of a digital camera

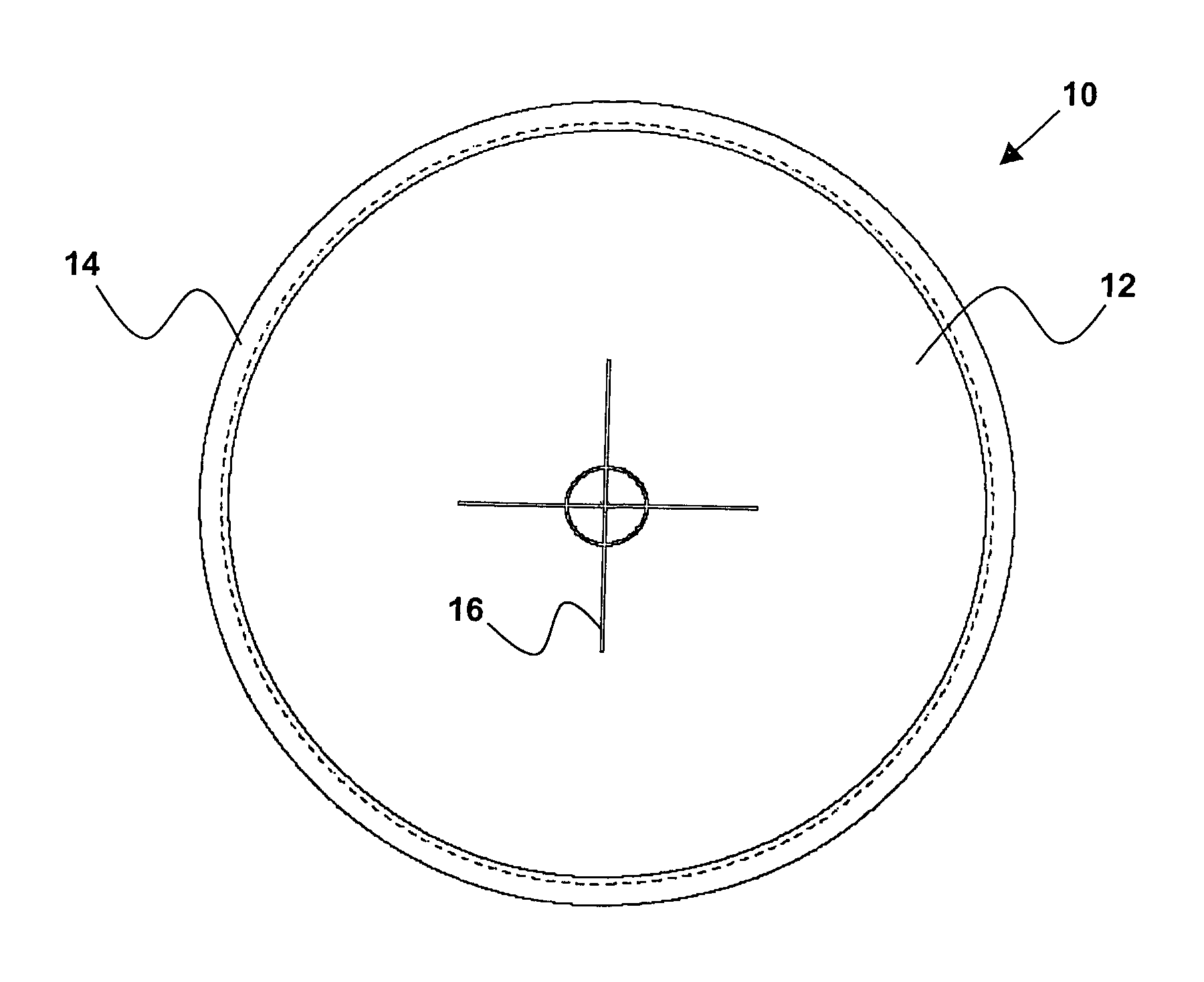

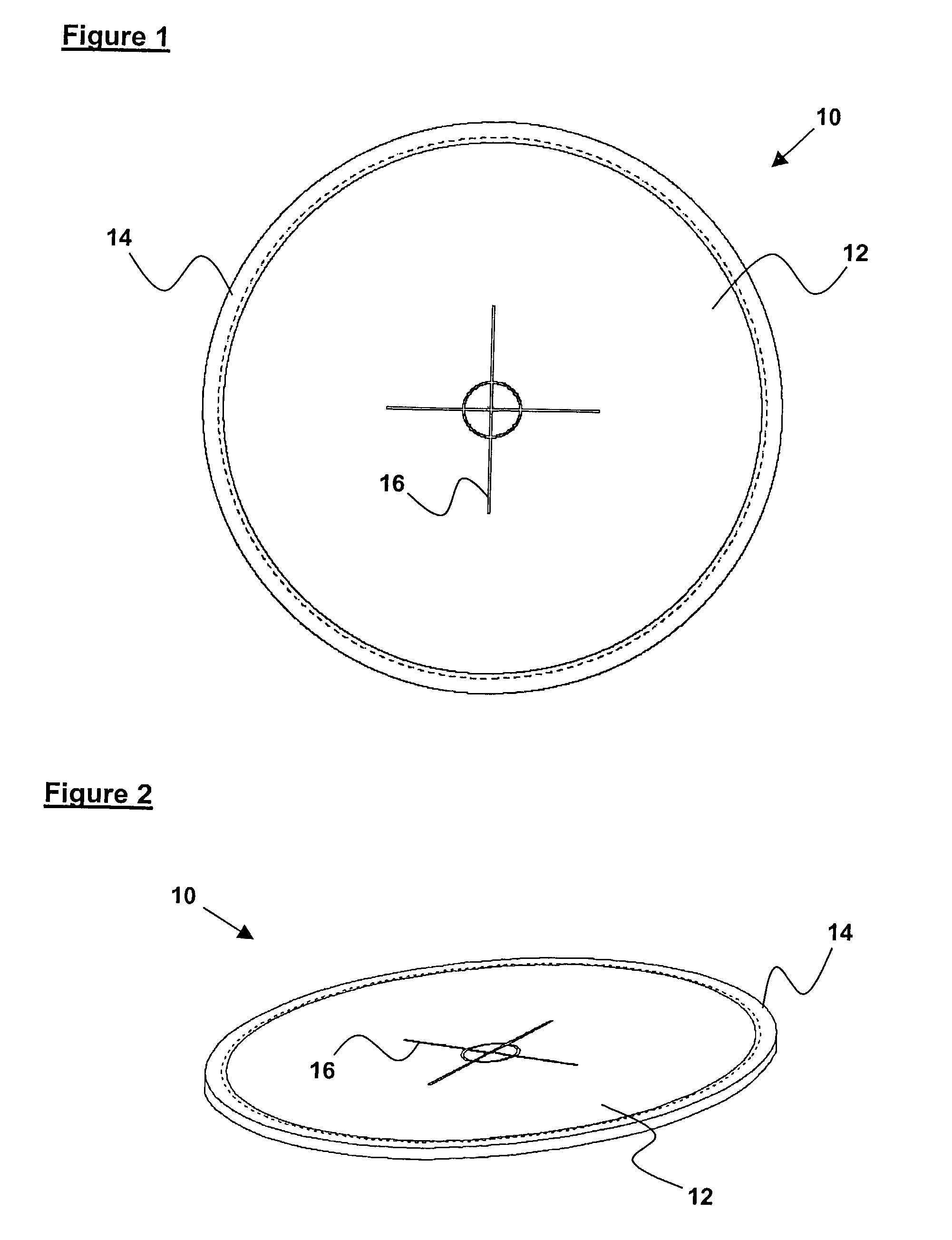

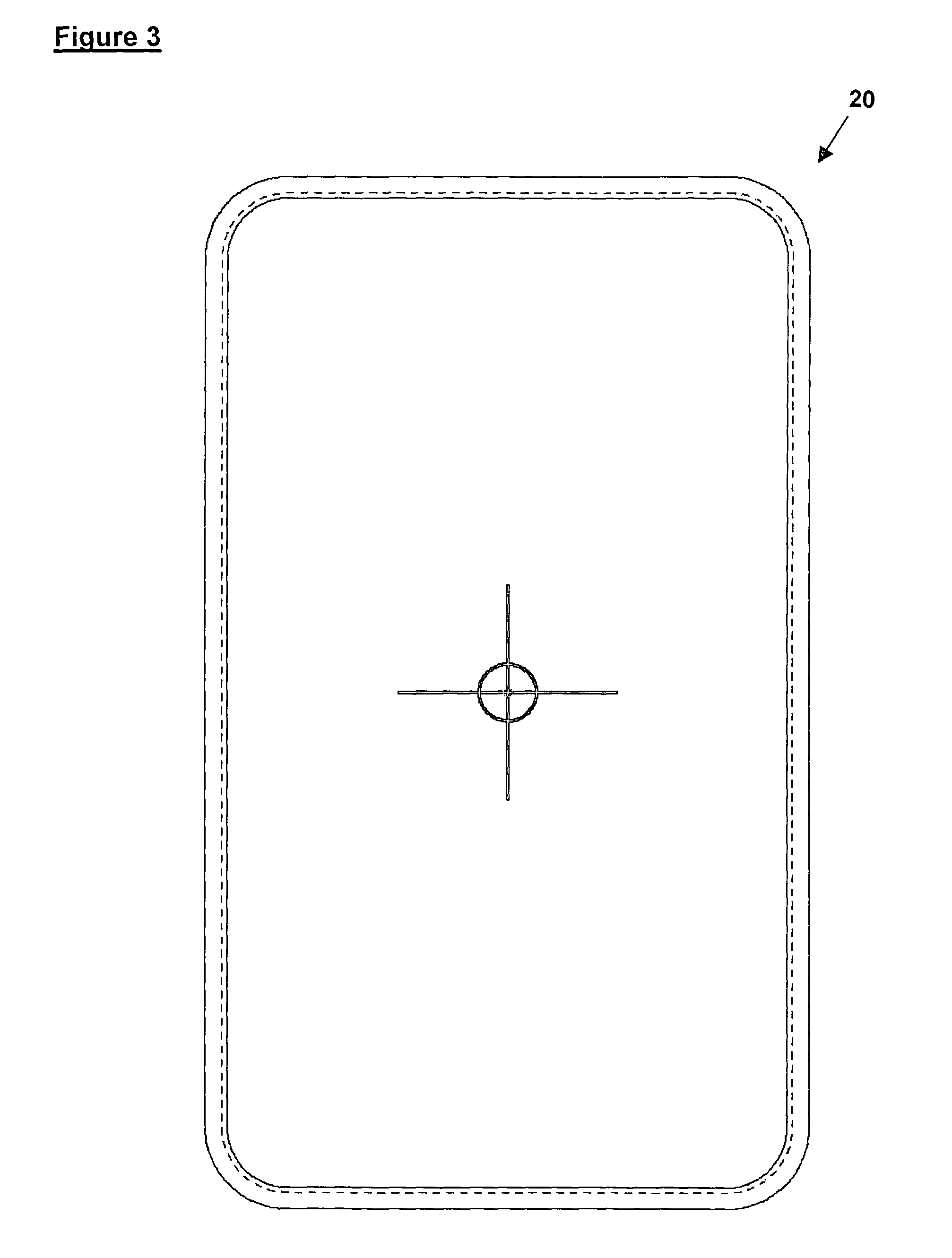

ActiveUS7885526B2Simple and quick to completeSuitableTelevision system detailsColor signal processing circuitsTarget surfaceLength wave

A target (10, 20) is disclosed suitable for setting the exposure and white balance of a photographic digital camera. The target (10, 20) comprises a target surface (12) that has a reflectance of 18% for all wavelengths of visible light. The target surface (12) is provided with a feature (16) upon which the camera is able to focus.

Owner:VITEC IMAGING SOLUTIONS UK LTD

Silver halide photographic light-sensitive material and package thereof

InactiveUS20050287485A1Process stabilityEasily causedSensitometric processesPhotosensitive material auxillary/base layersOptical densitySilver halide

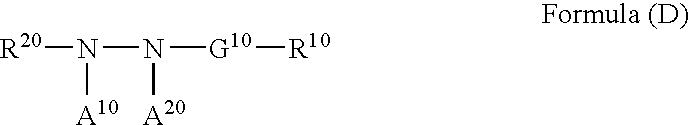

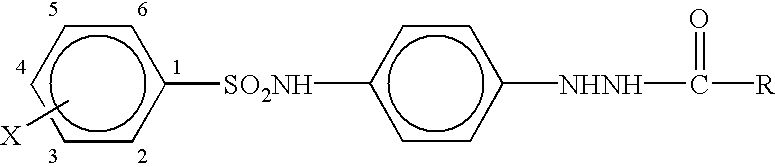

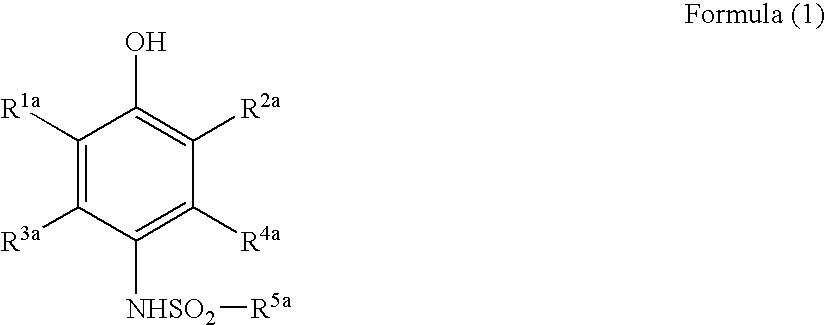

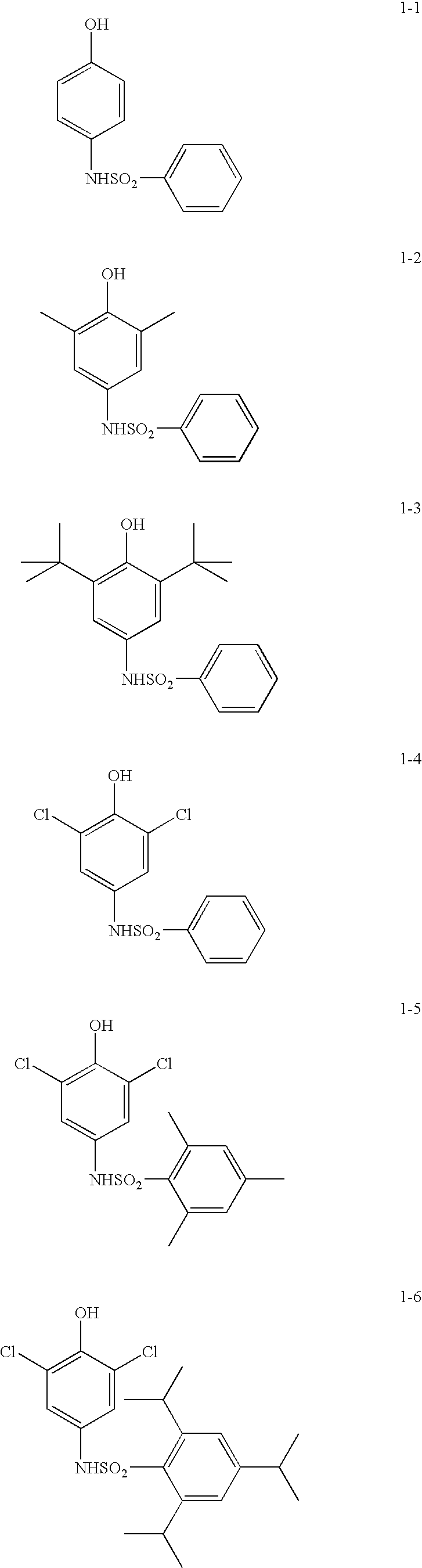

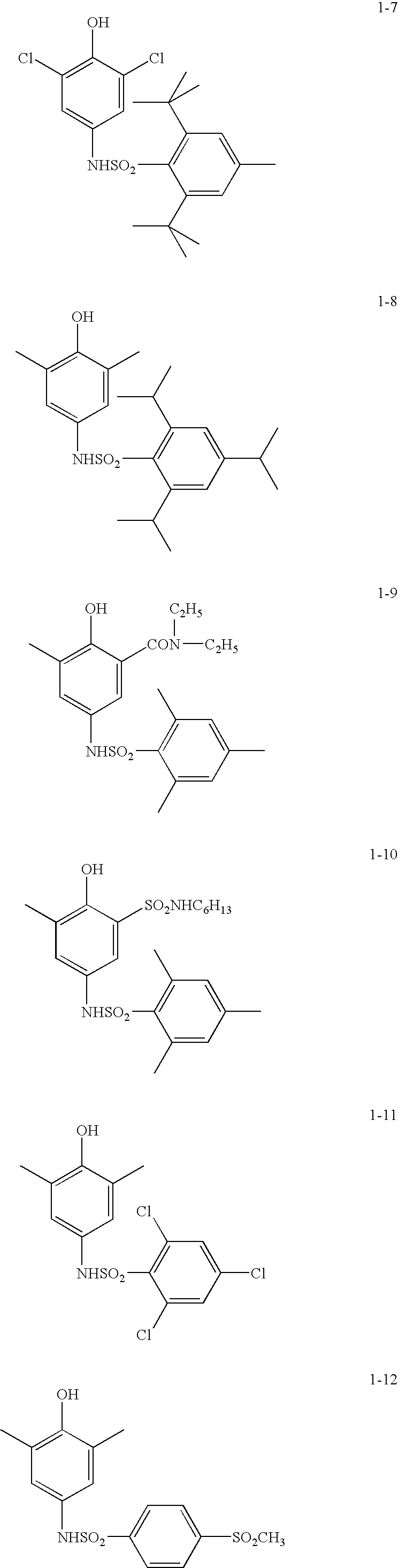

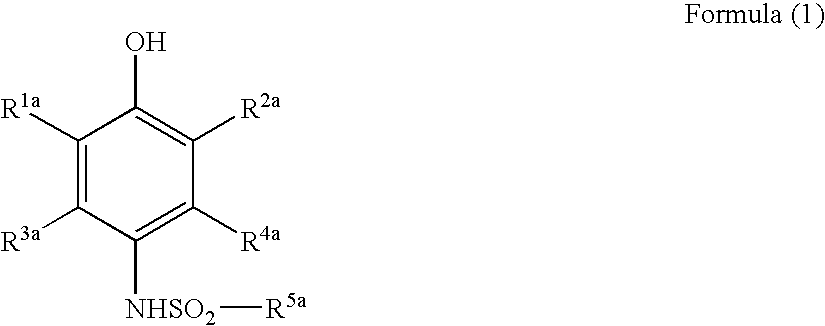

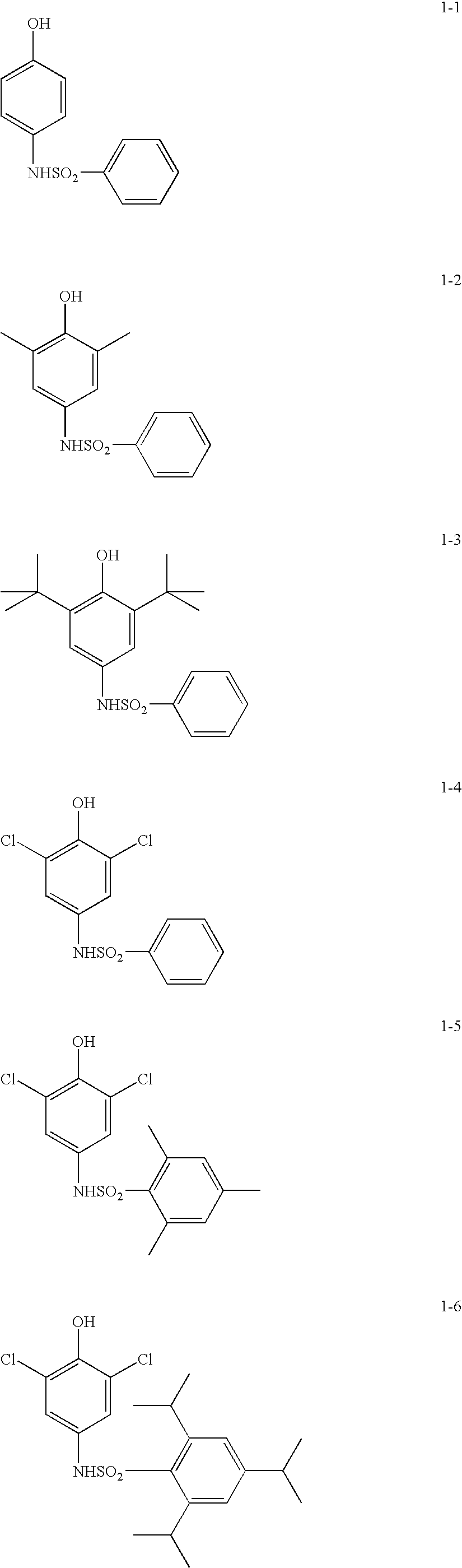

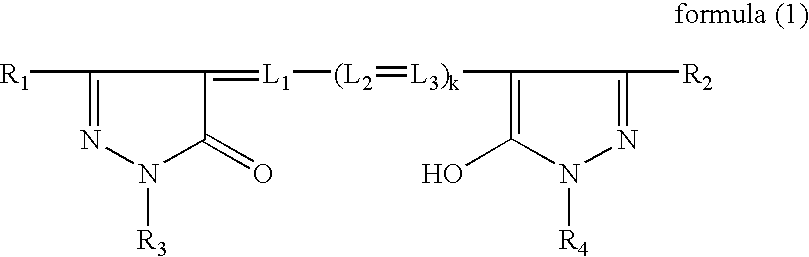

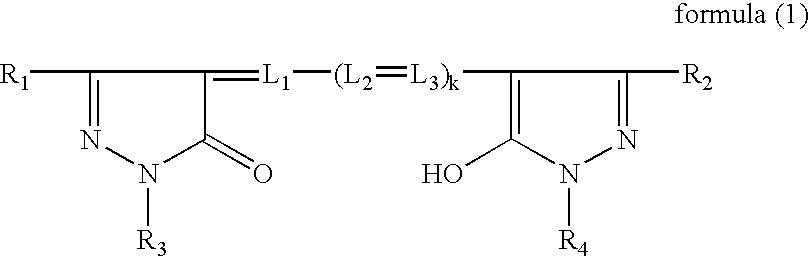

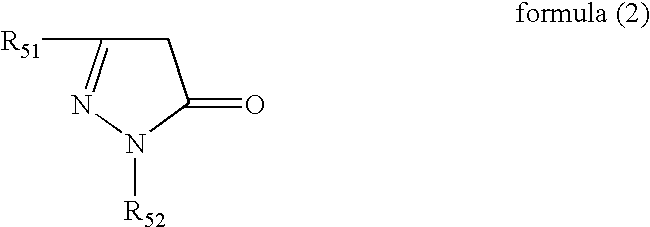

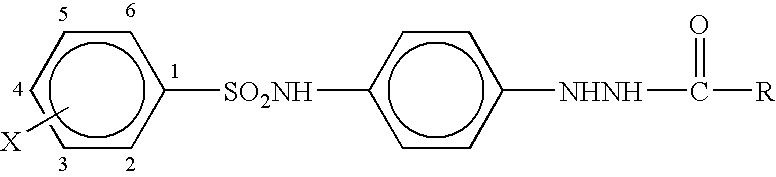

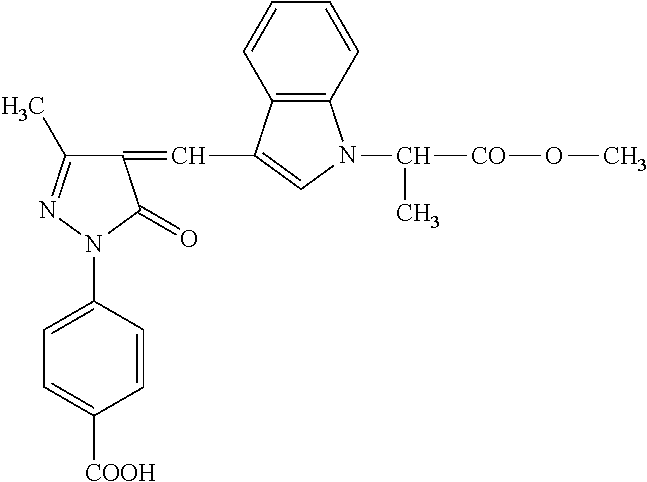

Disclosed is a silver halide photographic light-sensitive material having a layer containing a compound of the following formula and a fluorine compound, and has a gamma of 5.0 or more for the optical density range of 0.3 to 3.0: wherein R1 is alkyl or alkenyl, R2 are H, alkyl, alkenyl, aralkyl or aryl, l1 is 1-10, m1 is 1-30, n1 is 0-4, a is 0 or 1, and Z1 is OSO3M or SO3M where M is cation.

Owner:FUJIFILM CORP

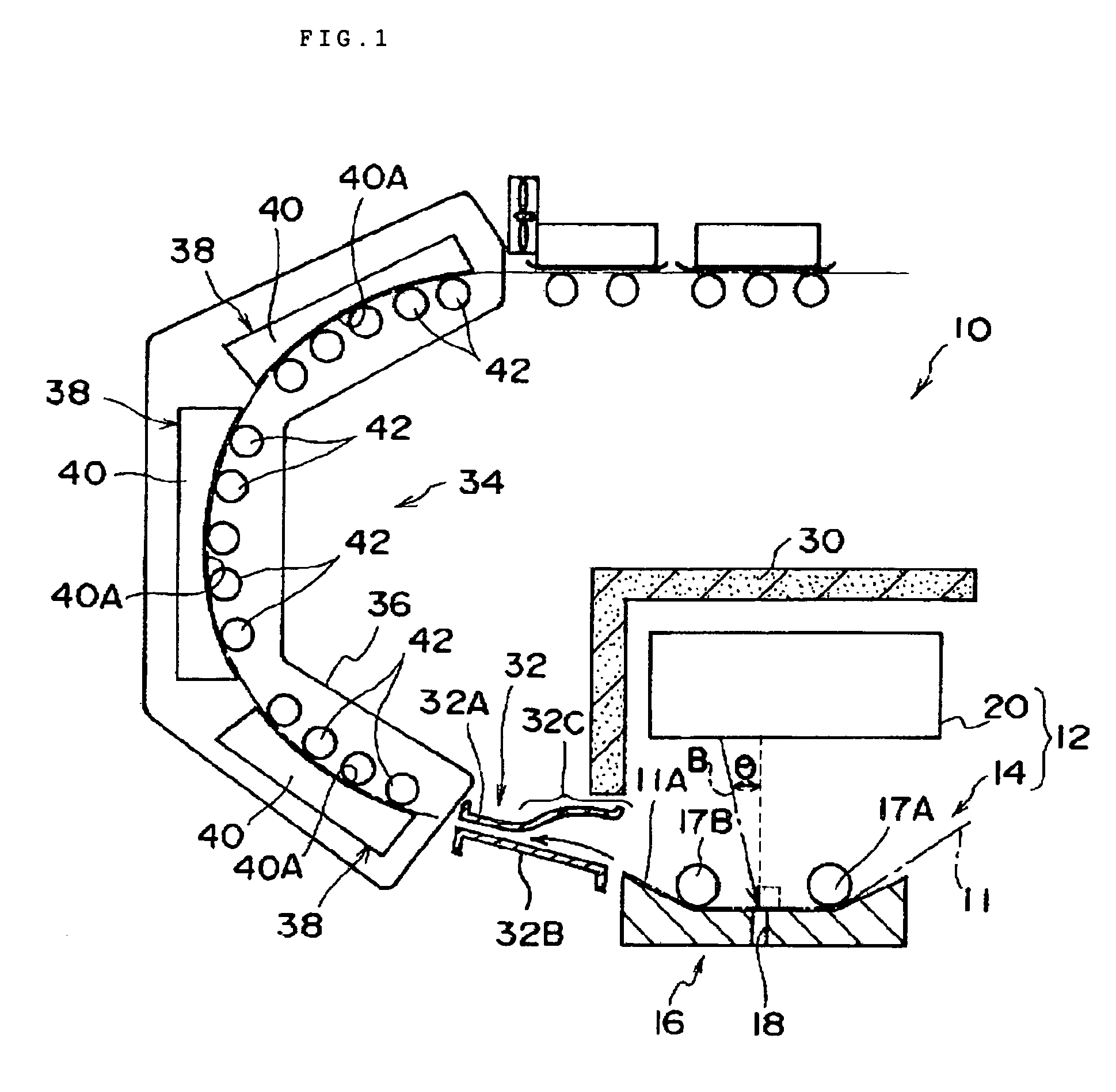

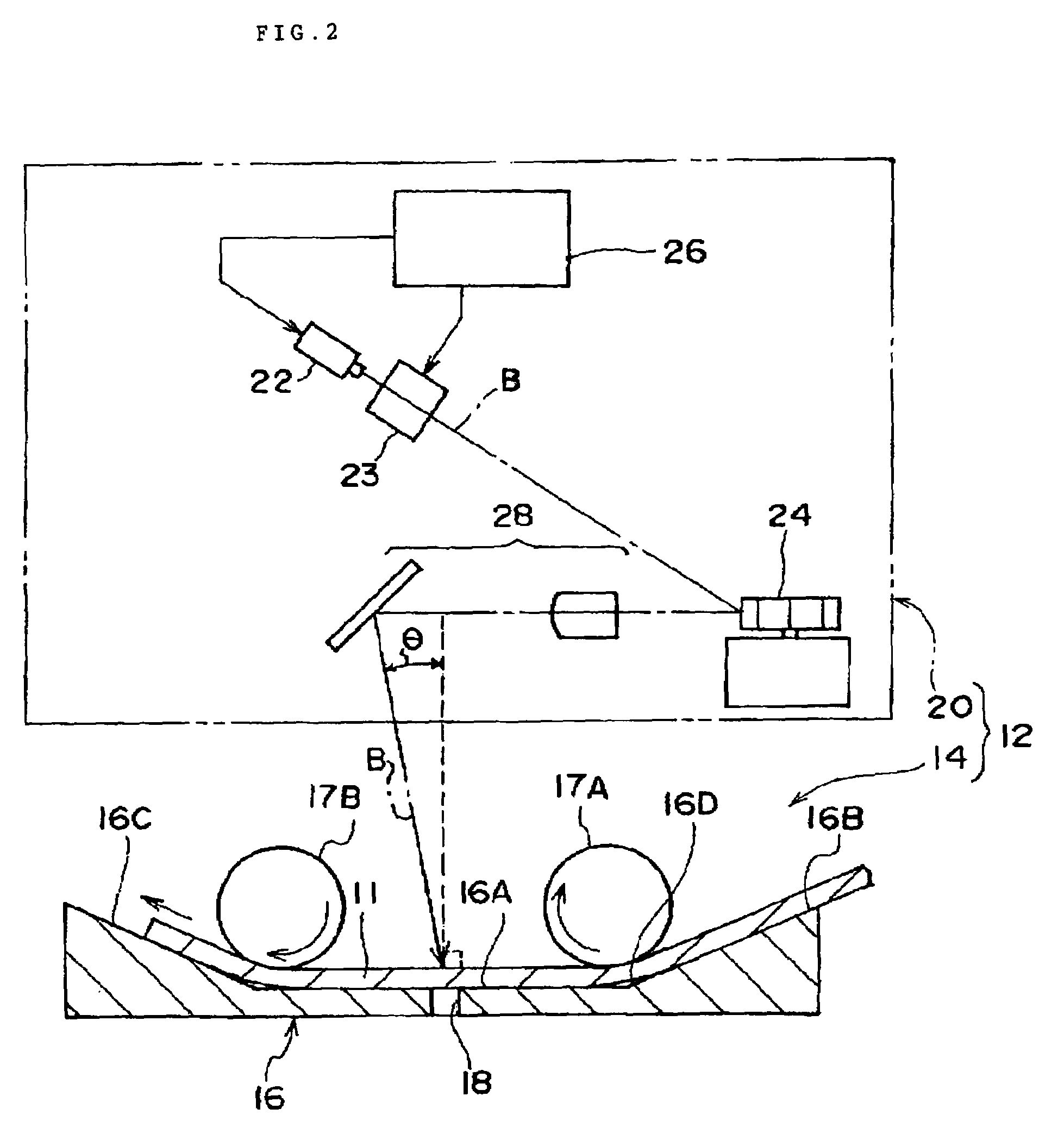

Thermal developing appts. and thermal developing method and program

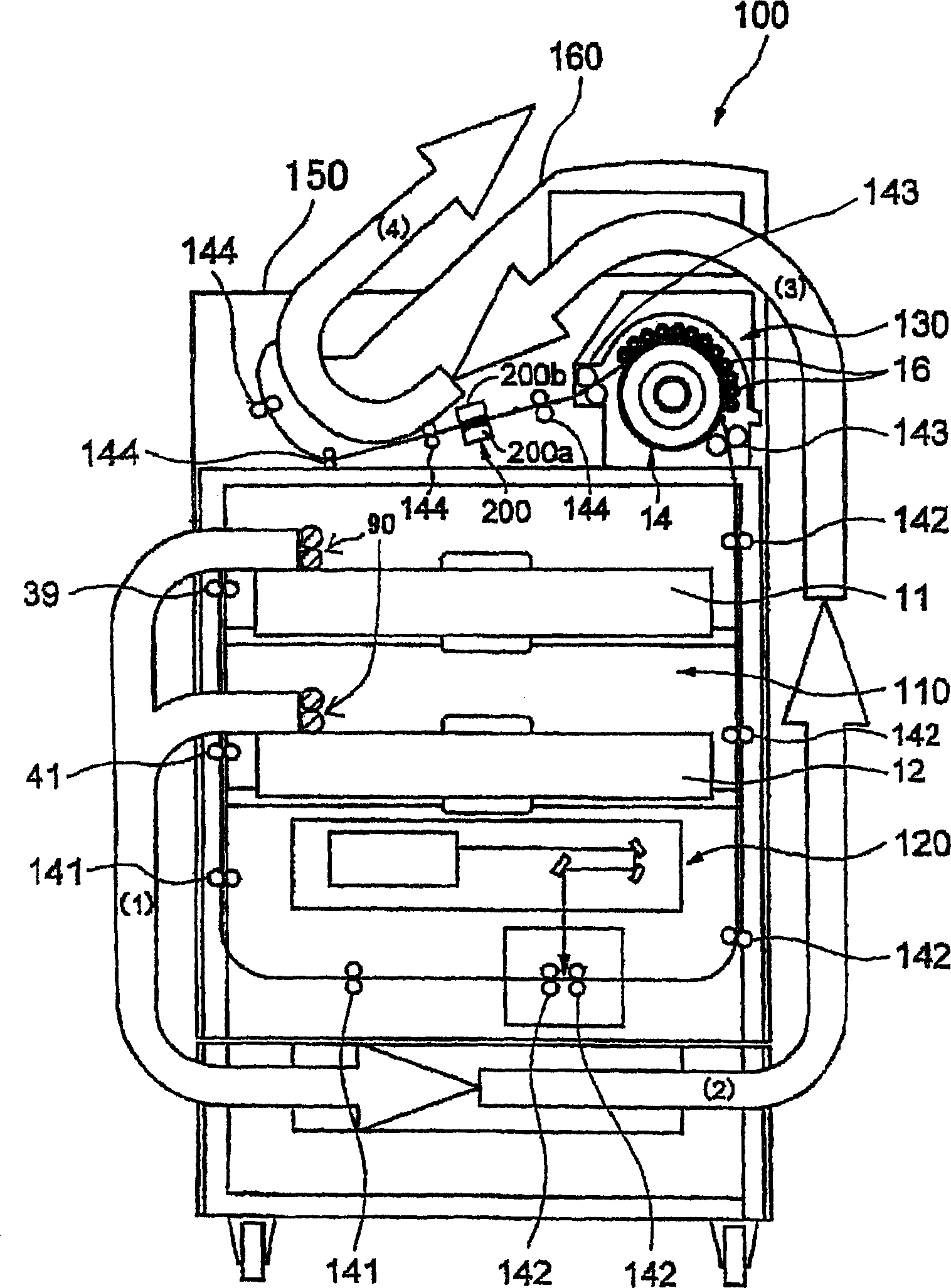

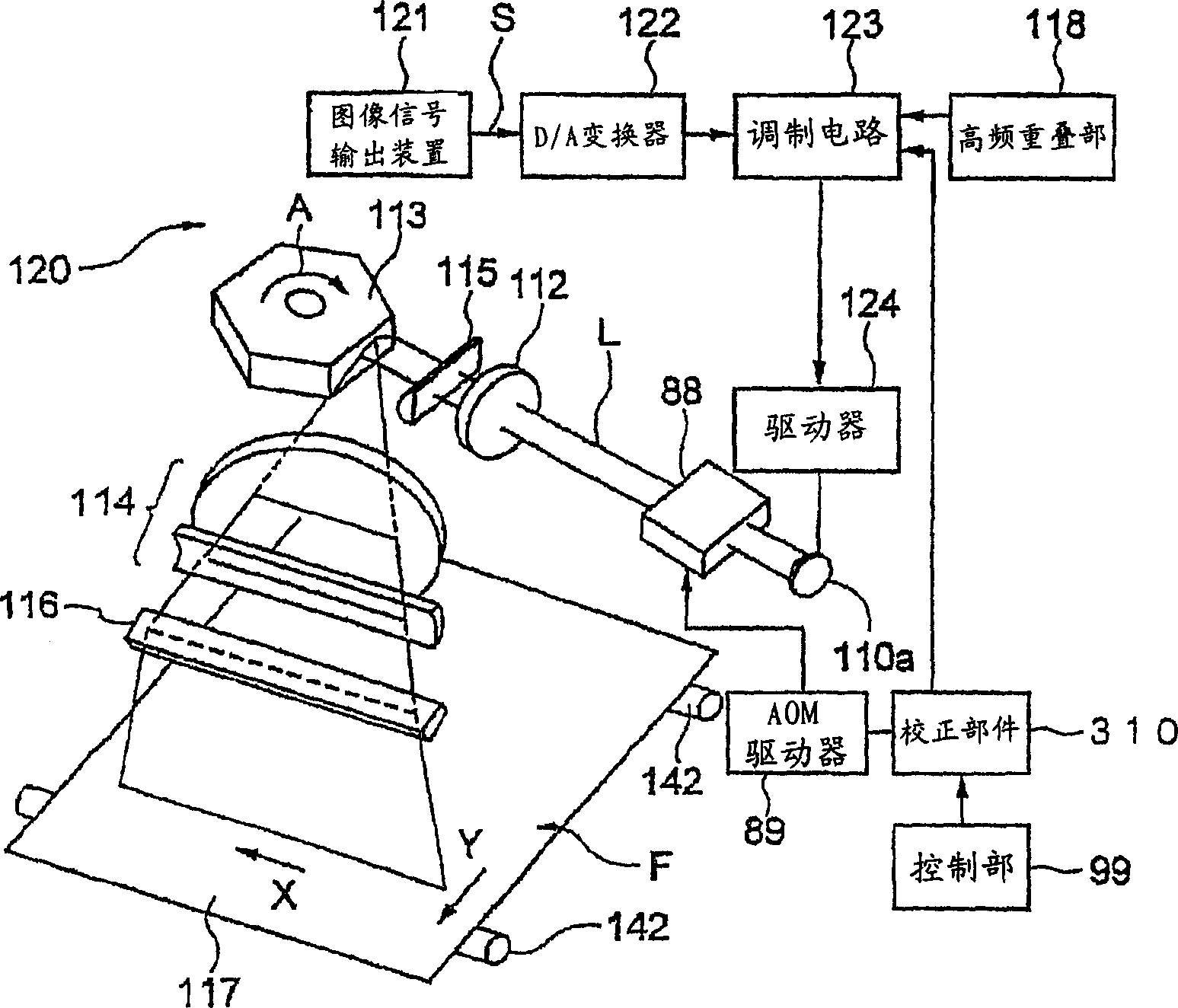

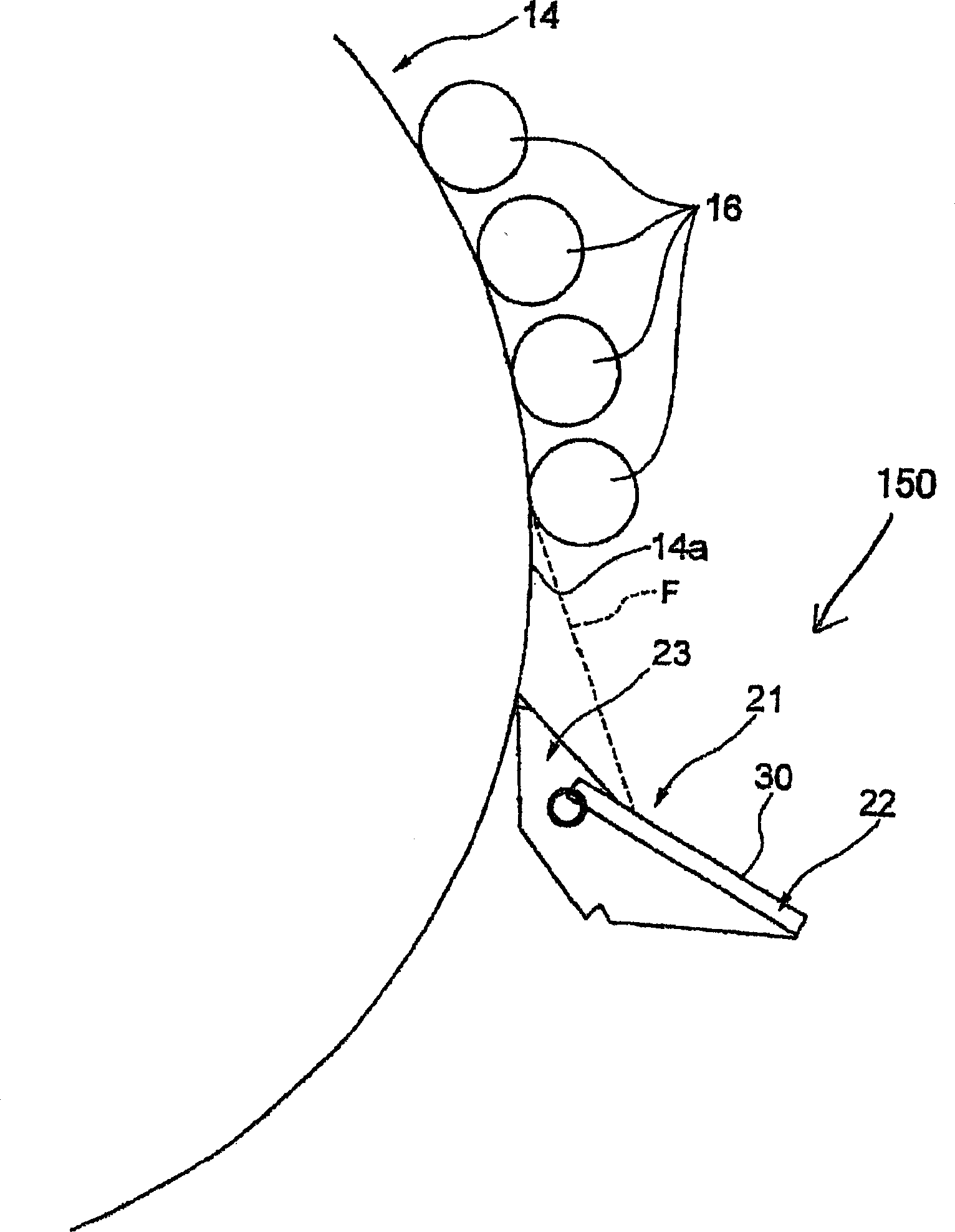

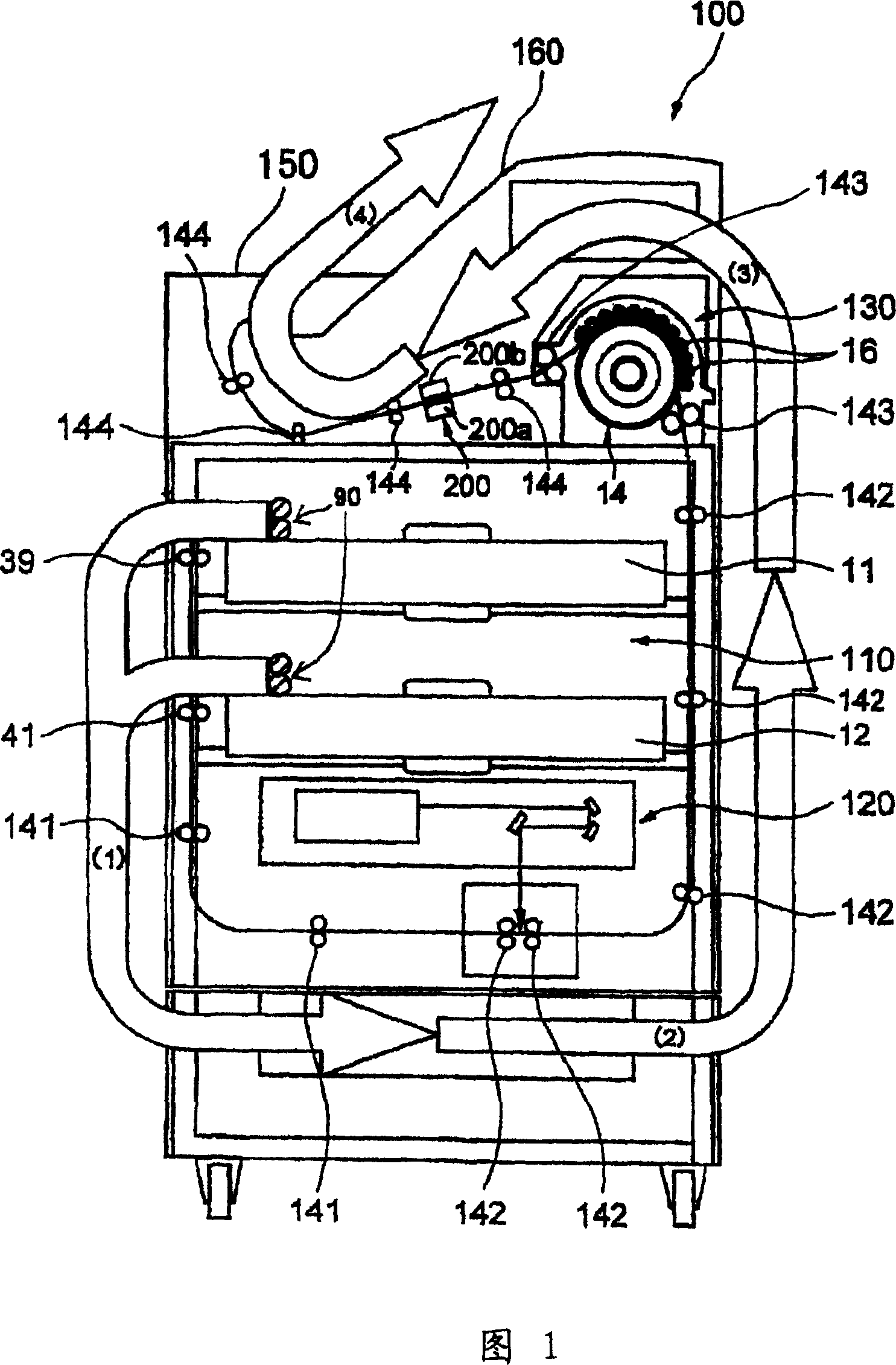

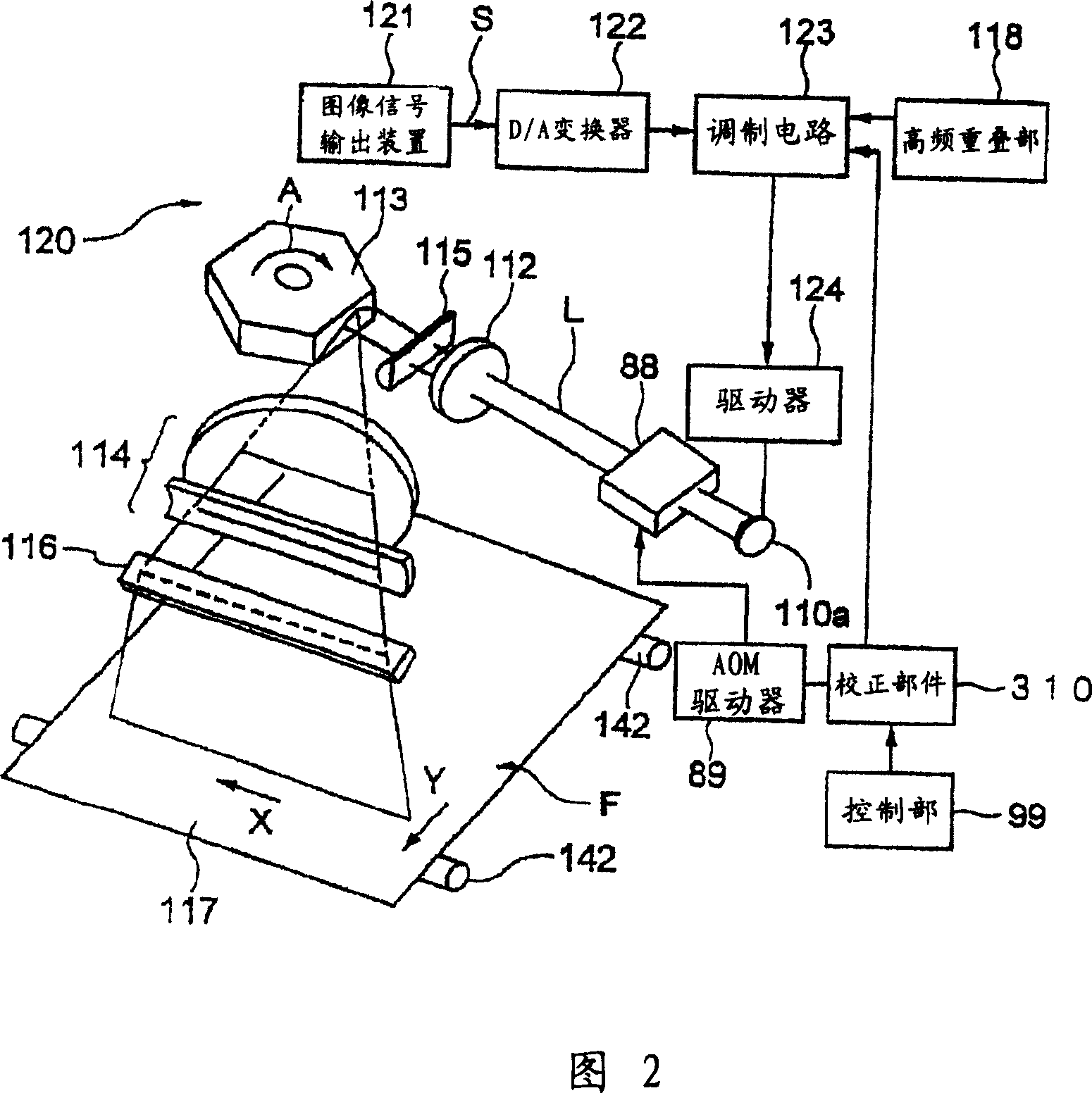

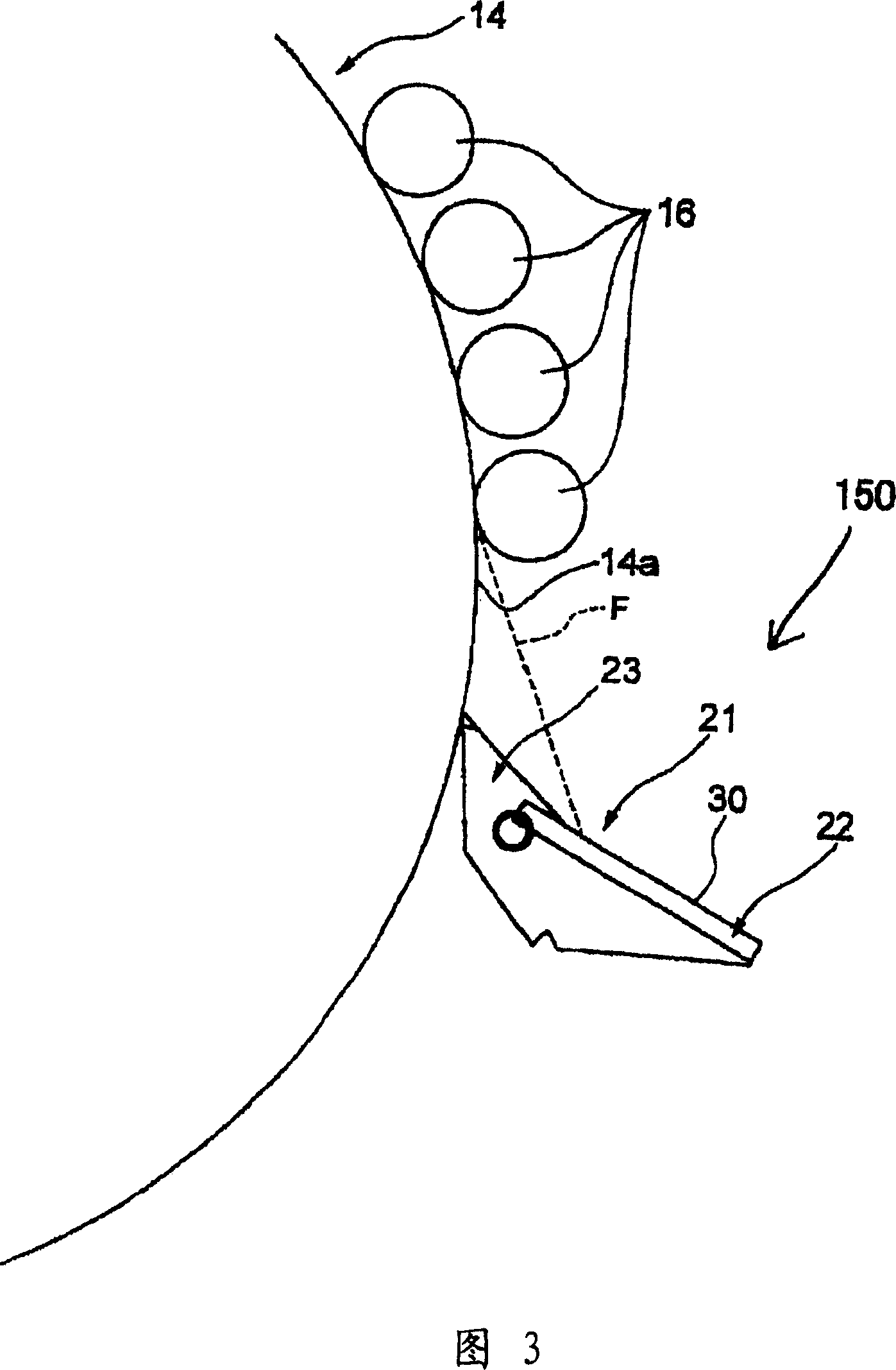

InactiveCN1519646AAppropriate density gray scaleStable concentrationSensitometric processesProcessingImaging processingLatent image

An image processing apparatus, comprising: an exposing device for exposing an image forming material so as to form a latent image on the image forming material based on image data; a thermal developing device for developing and visualizing the latent image on the exposed image forming material so as to form an image; a measuring device for measuring the image density of the image on the developed image forming material; a calibrating device for forming a table to define a relation between an image signal and image density on the basis of plural different test image data and measured-image densities thereof; a counting device for counting the number of the image forming material developed within predetermined time; and a controlling device for controlling the exposing device, the thermal developing device, the measuring device, the calibrating device and the counting device; wherein the controlling device stop forming the table for predetermined time when the counting device counts the number of the developed image forming material more than predetermined number.

Owner:KONICA MINOLTA INC

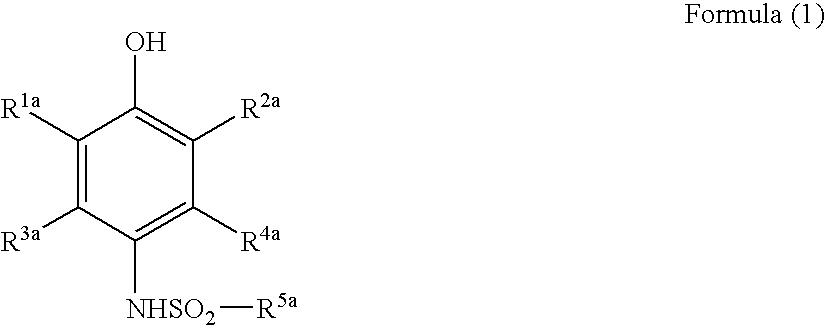

Silver halide photosensitive material and method of forming image

InactiveUS20050227188A1Photo-taking processesMulticolor photographic processingCompound (substance)Image formation

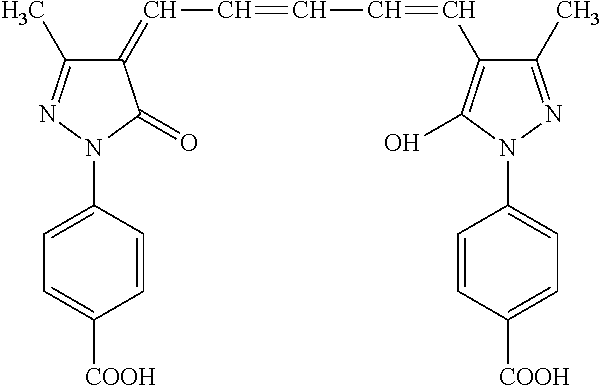

The present invention provides a method of forming a digital images exhibiting superior clearness in line images and superior visual whiteness. An image forming method of the invention comprises exposing a silver halide photographic material and processing the photographic material, wherein the photographic material contains a compound represented by the following formula (1) and a white area of the processed photographic material exhibits perception chromaticity indexes a and b of from 0.0 to +2.0 and from −2.2 to −4.0, respectively, in which the foregoing a and b are defined in JIS-Z-8730 and measured in accordance with a method defined in JIS-Z-8722:

Owner:KONICA MINOLTA PHOTO IMAGING

Silver halide photographic light-sensitive material

InactiveUS7094525B2Multicolor photographic processingSensitometric processesOrganic matterSilver halide

Disclosed is a silver halide photographic light-sensitive material having a support containing a filler and / or an undercoat layer containing a clay compound coated with an organic substance between the support and an emulsion layer or between the support and a back layer. The silver halide photographic light-sensitive material shows good dimensional stability in a processing system.

Owner:FUJIFILM CORP

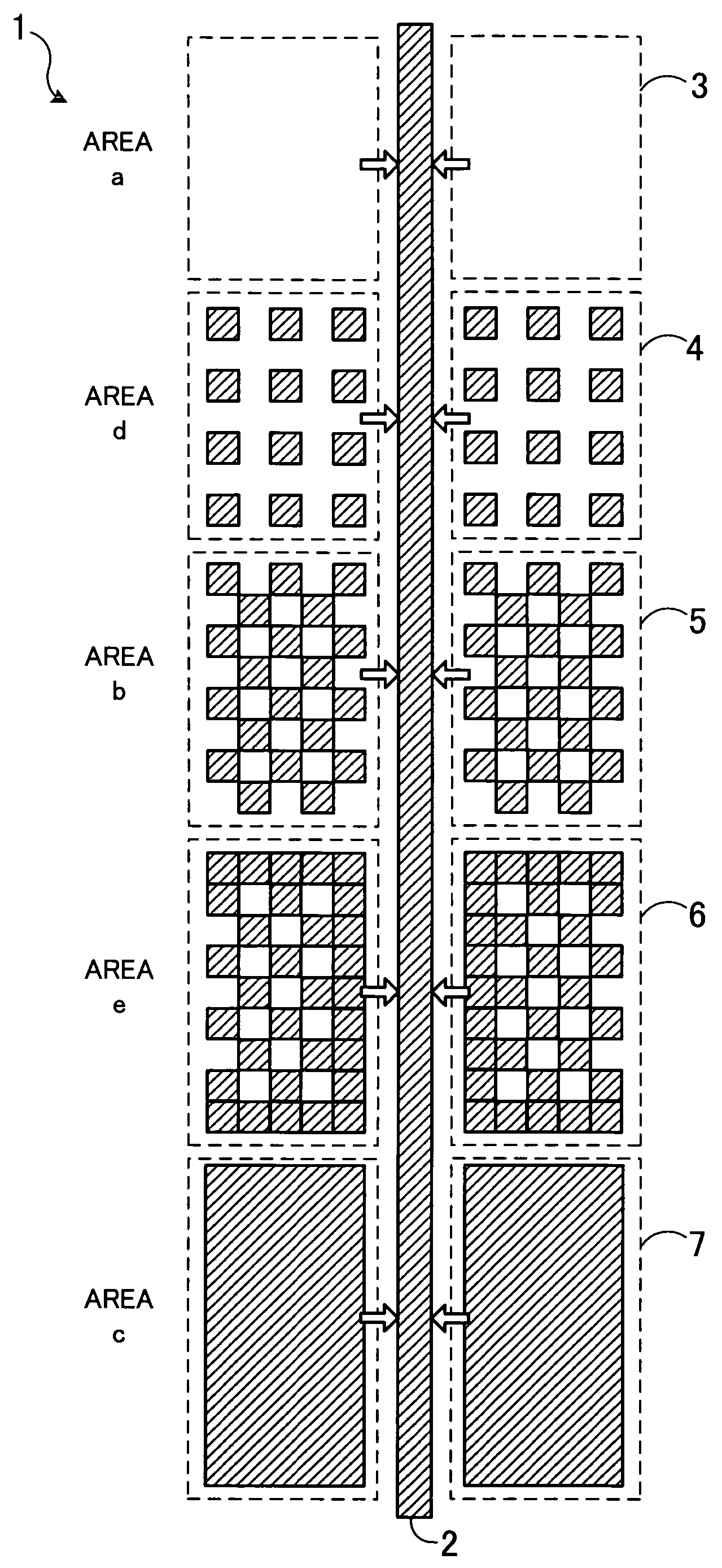

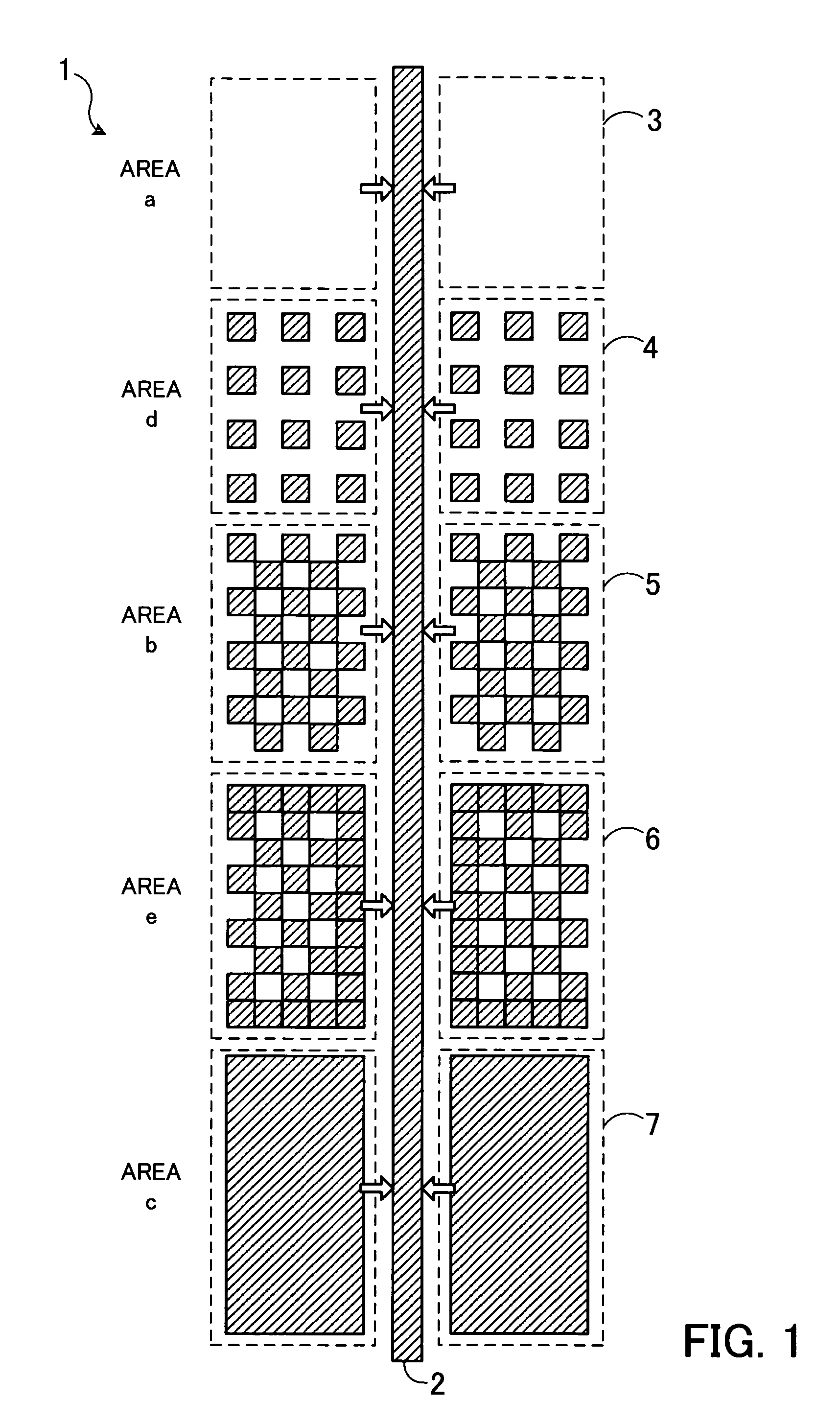

Mask, method for forming a pattern, and method for evaluating pattern line width

InactiveUS7459244B2Electric discharge tubesSemiconductor/solid-state device manufacturingLine widthRate change

A mask having a mask pattern for properly evaluating pattern line width. A mask pattern including a pattern to be determined and a plurality of surrounding patterns is formed on a mask. Areas with the same line width in the pattern to be determined are located between a pair of surrounding patterns with an aperture rate of 0%, between a pair of surrounding patterns with an aperture rate of 50%, and between a pair of surrounding patterns with an aperture rate of 100%, respectively. These pairs of surrounding patterns with the different aperture rates change the influence of charge-up on the pattern to be determined. Accordingly, the line width of each area in the pattern to be determined is determined, the difference between the line width of two areas is found, and the amount of a determination error caused by the charge-up is calculated. As a result, whether the line width of the pattern is determined with accuracy can be judged and the line width of the pattern can be evaluated properly.

Owner:FUJITSU SEMICON LTD

Photothermographic imaging material and method for forming image

InactiveUS20060084016A1High densityLight colorDiffusion transfer processesX-ray/infra-red processesCompound (substance)Leuco dye

A photothermographic imaging material including a support; an image forming layer containing an organic silver salt, a photosensitive silver halide, a binder and a silver ion reducing agent, the image forming layer being provided on the support; and a cyan coloring leuco dye. The photosensitive silver halide contains silver halide grains having a mean particle size of 10 to 50 nm, and the silver ion reducing agent is a compound represented by the following Formula (A-3).

Owner:KONICA MINOLTA INC

Silver halide photographic light-sensitive material

InactiveUS6828088B2Simple materialSensitometric processesSilver halide emulsionsCyanide ligandOrthogonal coordinates

Disclosed is a silver halide photographic light-sensitive material comprising at least one silver halide emulsion layer on a support, wherein 40 mol % or more of silver halide contained in the silver halide emulsion layer is silver bromide and the silver halide contains 1x10<-6 >mole or more per mole of silver of a metal complex containing one or more cyanide ligands, and the silver halide photographic light-sensitive material has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 4.0 or more for the optical density range of 0.1-1.5. There is provided a silver halide photographic light-sensitive material showing high contrast and high sensitivity.

Owner:FUJIFILM CORP

Photothermographic material and image forming method

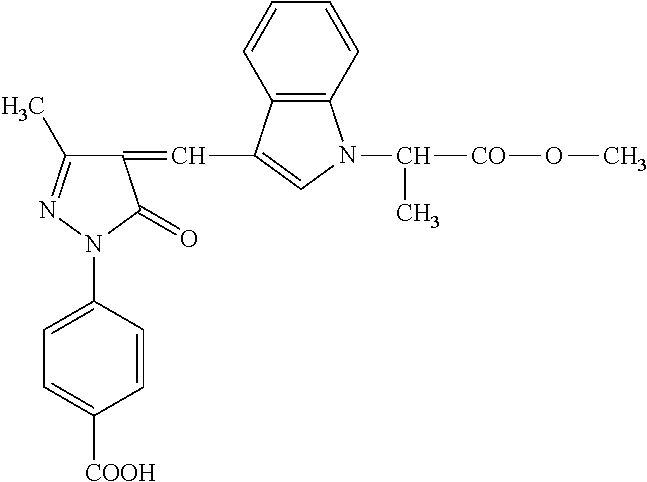

InactiveUS20050064350A1Low costHigh spectral sensitizationX-ray/infra-red processesMulticolor photographic processingImage formationHeat sensitive

The present invention provides a photothermographic material including on one surface thereof a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent and a binder, and satisfying a relationship of image tone defined by Expression (1): (a*121t−a*117t)2+(b*121t−b*117t)2<2, (1) wherein a*121t and b*121t each represent a value of CIELa*b* obtained by thermal development at a developing temperature of 121° C. for t (sec), and a*117t and b*117t each represent a value of CIELAB obtained by thermal development at a developing temperature of 117° C. for t (sec), the values occurring at an optical density of 1.2; and t represents a duration (sec) required to attain a maximum density when the material has been exposed to sufficient light for producing Dmax and is developed at 121° C. The invention also provides an image forming method using the photothermographic material.

Owner:FUJIFILM CORP +1

Silver halide photosensitive material and process of producing black and white image using the same

InactiveUS8133665B2Good effectHigh resolutionMulticolor photographic processingSensitometric processesSilver halideMaterials science

Disclosed is a silver halide photographic photosensitive material which includes a support and at least one silver halide photosensitive layer on the support, wherein the average equivalent sphere diameter of the silver halide of the silver halide photosensitive layer is 0.30 μm or less, the silver halide photosensitive layer includes four or more kinds of silver halide grains having mutually different average equivalent sphere diameters, and the thickness between a surface of the support at a side at which the silver halide photosensitive layer is provided and a surface of the silver halide photosensitive layer at a side opposite to the support is 10 μm or less.

Owner:FUJIFILM CORP

Silver halide photographic light-sensitive material

InactiveUS7229738B2Increase contrastGood storage stabilitySensitometric processesPhotosensitive material auxillary/base layersOrthogonal coordinatesLight exposure

Disclosed is a silver halide photographic light-sensitive material comprising at least one silver halide emulsion layer on a support, which contains a fluorine compound having two or more fluorinated alkyl groups having two or more carbon atoms and 11 or less fluorine atoms and having at least one of an anionic hydrophilic group and a nonionic hydrophilic group, and has a characteristic curve drawn in orthogonal coordinates of logarithm of light exposure (x-axis) and optical density (y-axis) using equal unit lengths for the both axes, on which gamma is 5.0 or more for the optical density range of 0.3-3.0. There is provided a silver halide photographic light-sensitive material that provides high sensitivity, high contrast, favorable half tone dot quality and superior storage stability.

Owner:FUJIFILM CORP

Polyolefine sheet based display material with tone strengthening layer

InactiveCN1357794AShort rinse timeMulticolor photographic processingSensitometric processesPolyolefinEngineering

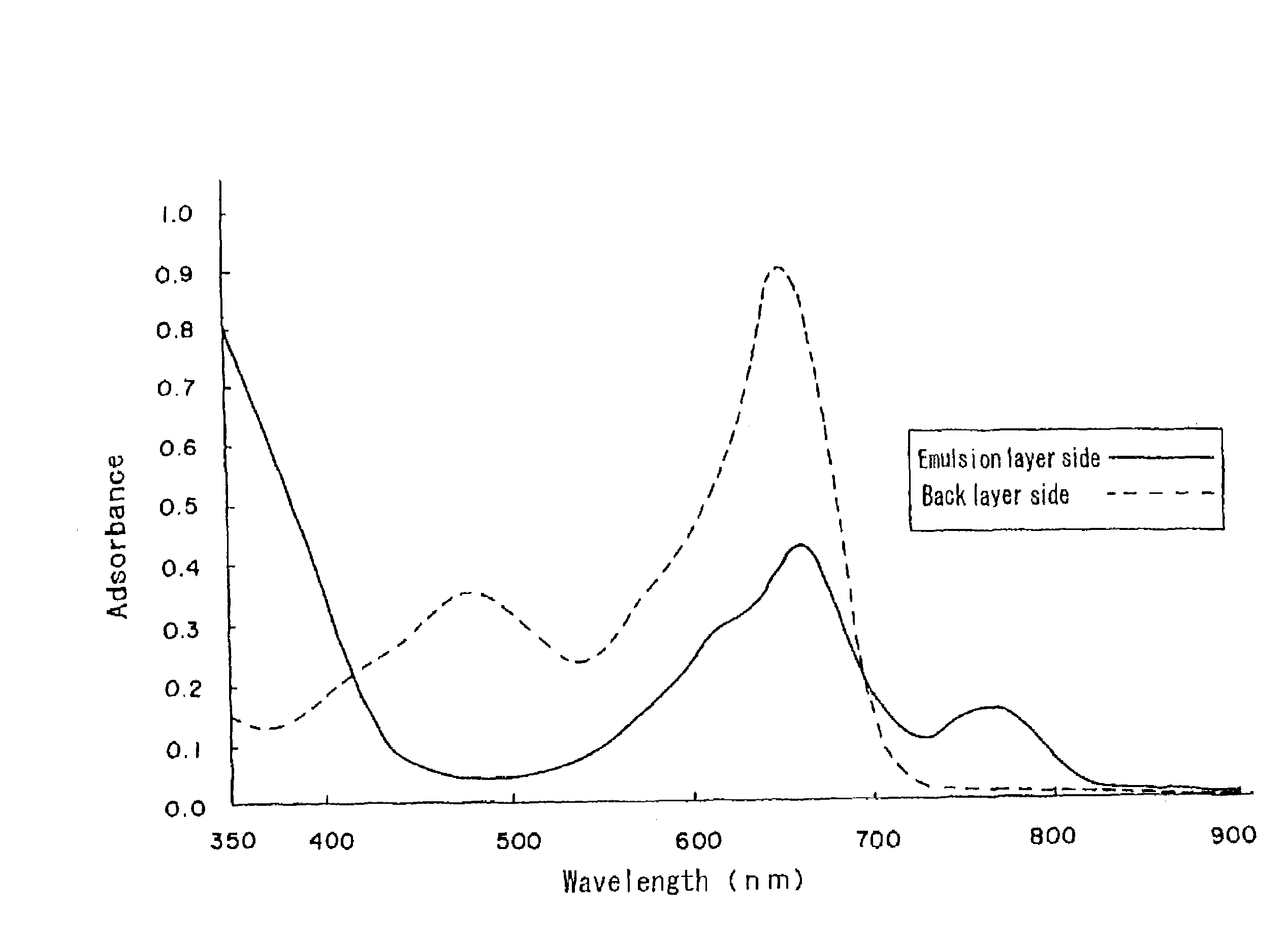

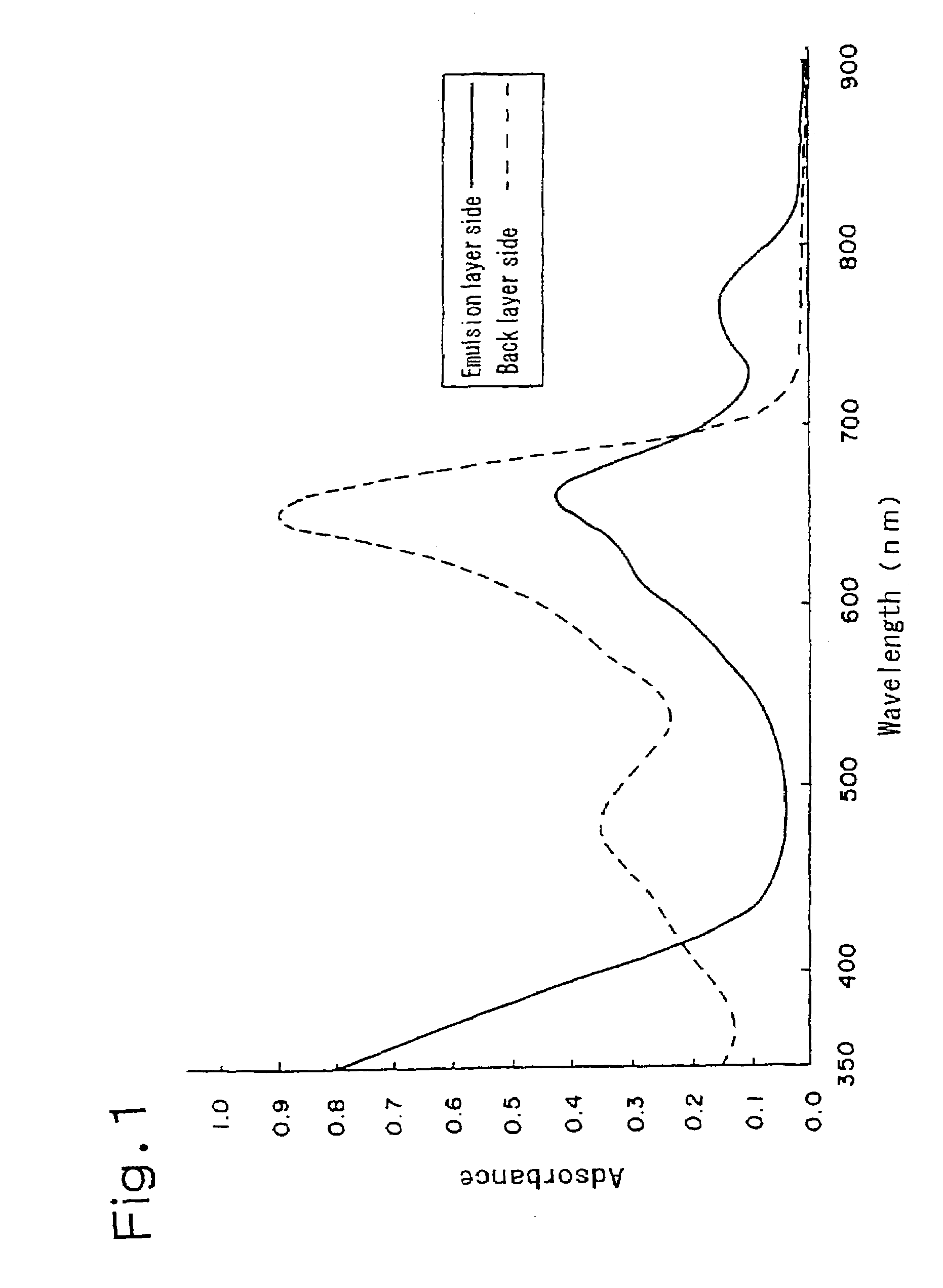

The invention relates to a display material comprising a base said base comprising a polyolefin sheet comprising at least one voided polyolefin diffusion layer, at least one topside photosensitive silver halide layer on the topside of said base and at least one bottom side photosensitive layer on the bottom side of said base, below said bottom side emulsion a tone enhancing layer and below said tone enhancing layer an antihalation layer wherein said display material has a light transmission of between 35 and 60 percent in the developed Dmin areas of the display material.

Owner:EASTMAN KODAK CO

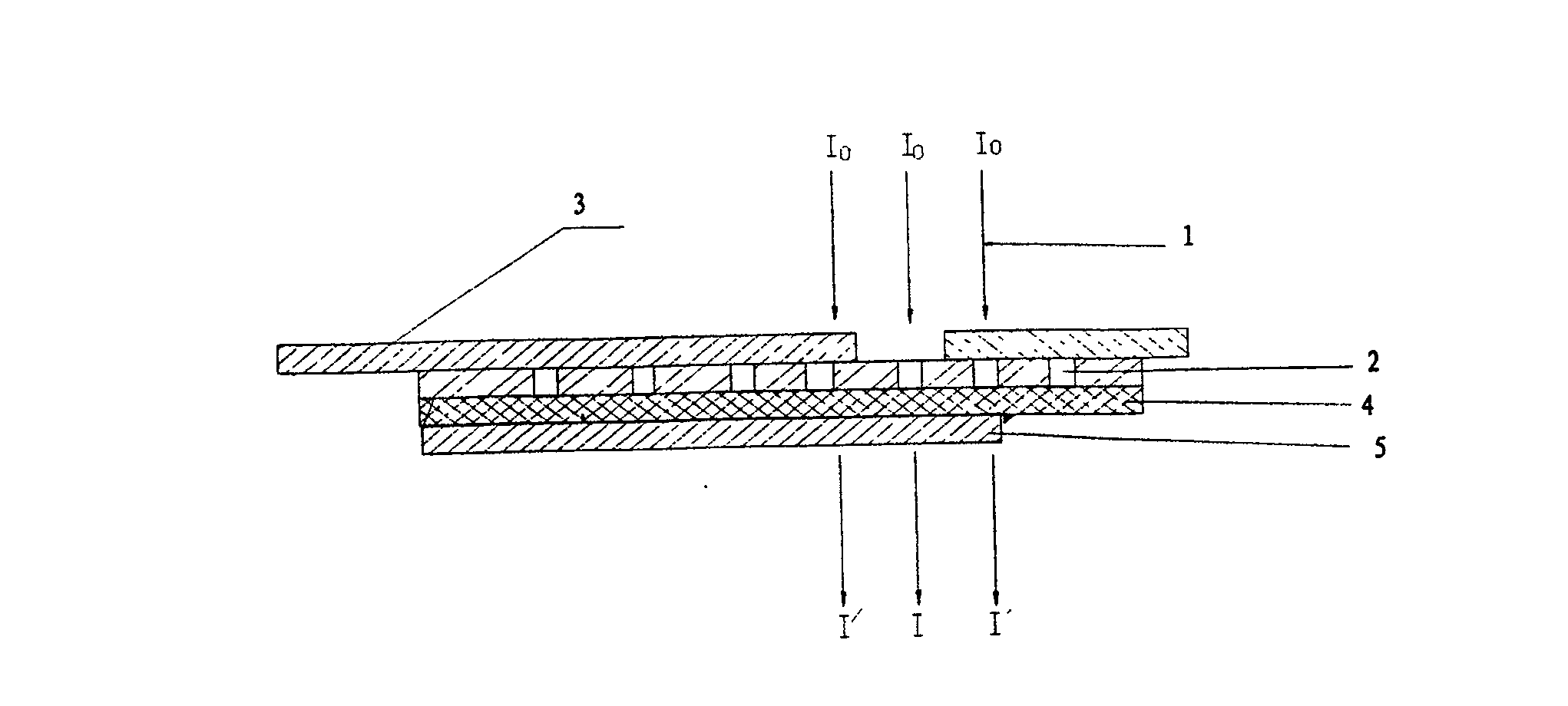

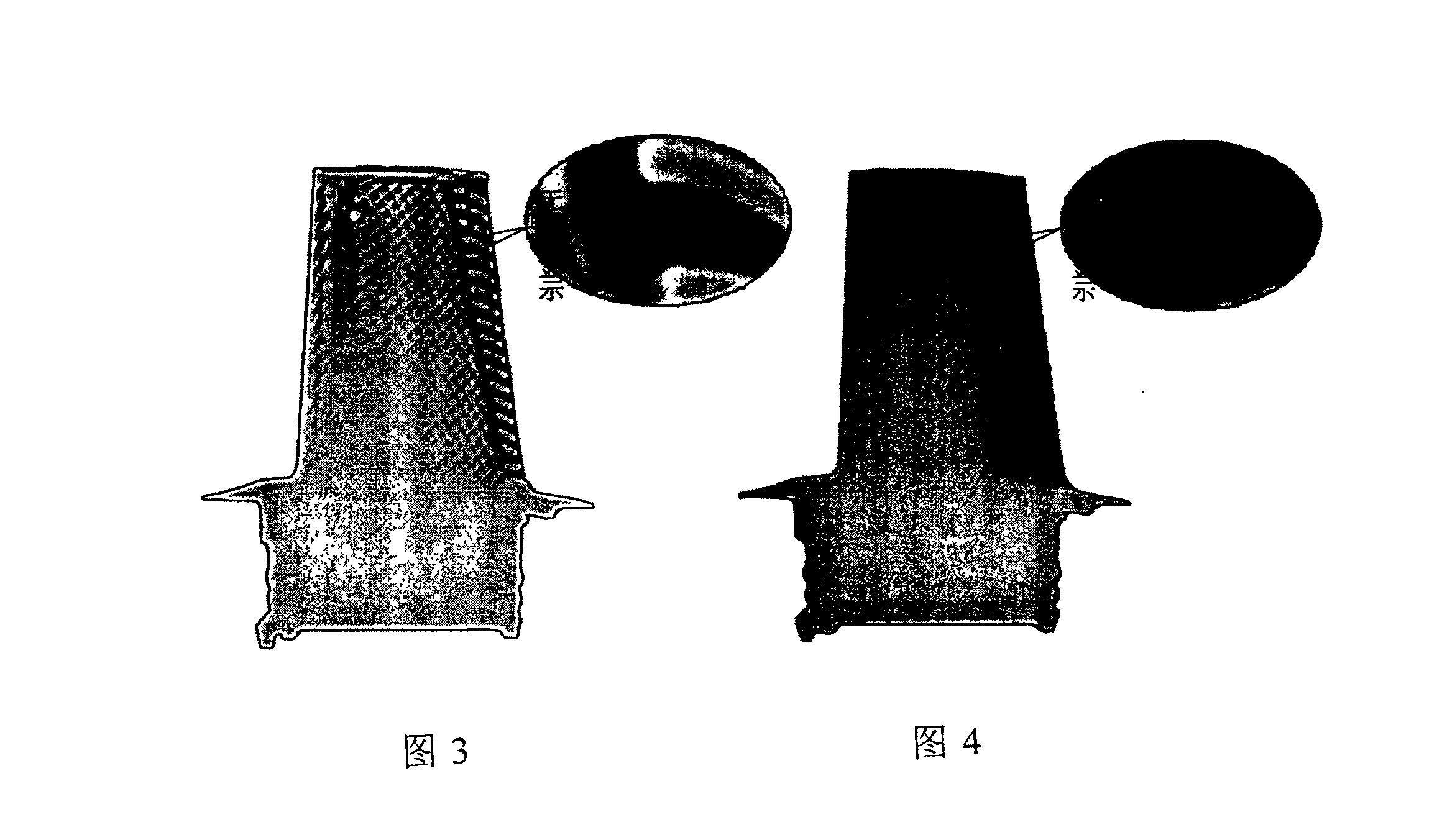

Radiographic inspection compensation method

InactiveCN100545642CSimple processEasy to operateSensitometric processesMaterial analysis by transmitting radiationUltrasound attenuationPresent method

The invention relates to a method for radiographic inspection and compensation. The key point is to use a comparison method to measure the blackness value of different films, and use the characteristic curve test data of different films to make different film characteristic curves and select the film suitable for radiographic inspection. ; Verify the rationality and reliability of the effective transillumination area selection by measuring the beam uniformity of the X-ray machine; finally, before the parts are transilluminated, the density of the filling compensation powder should be the same or similar to the density of the material to be inspected, At the same time, the absorption and attenuation of rays should be similar. The particle size of the filling powder should be 0.1-0.3 mm, and the powder filling should be dense without leaving gaps. The advantages and effects of the present invention are that a reasonable and effective radiographic inspection process is provided, the inspection quality can be guaranteed, the method is simple, the operation is convenient, the efficiency is high, the equipment cost is low, and the cost can be greatly reduced. This method is suitable for general industrial production environment in the application.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Image processor, image processing method and programm

An image processing apparatus, comprising: an exposing device for exposing an image forming material so as to form a latent image on the image forming material based on image data; a developing device for developing and visualizing the latent image on the exposed image forming material so as to form an image; a measuring device for measuring the image density of the image on the developed image forming material; a calibrating device for forming a table to define a relation between an image signal and image density on the basis of plural different test image data and measured-image densities thereof; a storing device for storing a characteristic change model indicating a characteristic change of at least one of the exposing device and the developing device with time; a difference calculating device to calculate a density difference on the basis of the characteristic change model between the time of forming the table and the time of forming an image based on image signal of diagnostic image data; and a correcting device for correcting the table on the basis of the density difference calculated by the difference calculating device.

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com