Polyolefine sheet based display material with tone strengthening layer

A polyolefin, reinforcement layer technology for use in the field of base materials for photographic reflective and transmissive displays that addresses the problems of reduced shoulder and maximum density, unsatisfactory, and reduced imaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0152] The "spin-coated" samples were prepared by first preparing a solution (3% w / v) of the dye in di-n-butyl sebacate solvent. If the dye does not dissolve, add some dichloromethane to achieve dissolution. The solution was filtered and 0.1-0.2 mL was applied to a clear polyethylene terephthalate support (approximately 4 cm x 4 cm) and spin-coated using Model No. EC101 supplied by Headway Research Corporation, Garland, TX The equipment was spin coated at 4,000 RPM. The transmission spectra of the dye samples thus prepared were subsequently recorded.

[0153] Preferred "NB couplers" form dyes whose absorption spectrum in di-n-butyl sebacate on "spin coating" has an LBW of at least 15 nm, preferably at least 25 nm, which is 3% lower than that of the same dye in acetonitrile (w / v) value in solution.

[0154] In a preferred embodiment, the cyan coupler "NB coupler" used in the present invention has the formula (IA) in

[0155] R' and R" are substituents selected to make the...

Embodiment 1

[0238] Since the present invention is intended to be a display material that can be used as both a reflective and a transmissive display material, no prior art materials can be compared to it, which only function in a single mode.

[0239] The following laminated photographic display materials (invention) were prepared by extrusion laminating the following sheets to the top side of a photographic grade polyester base: Top Sheet (Emulsion Side):

[0240] Composite sheet consisting of 6 layers respectively labeled L1, L2, L3, L4, L5 and L6. L1 is the thin colored layer on the outside of the module, on which the photosensitive silver halide layer will be bonded. L2 is the layer added with optical brightener and 6% titanium dioxide. The optical brightener used was Hostalux KS, manufactured by Ciba-Geigy. The rutile titanium dioxide used was DuPont R104 (0.22 μm particle size titanium dioxide). Table 1 below gives the characteristics of the layers of the top biaxially oriented s...

Embodiment 2

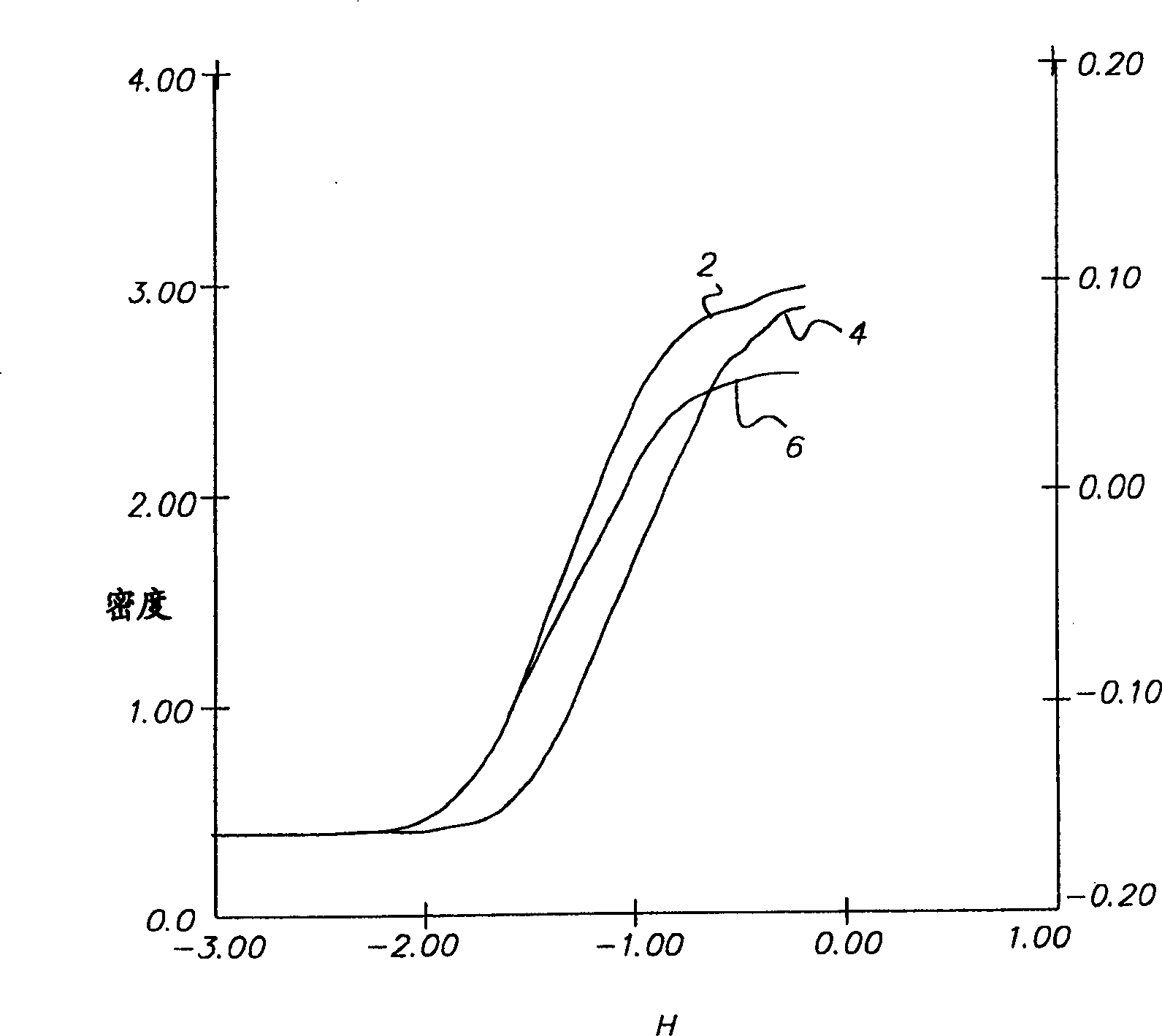

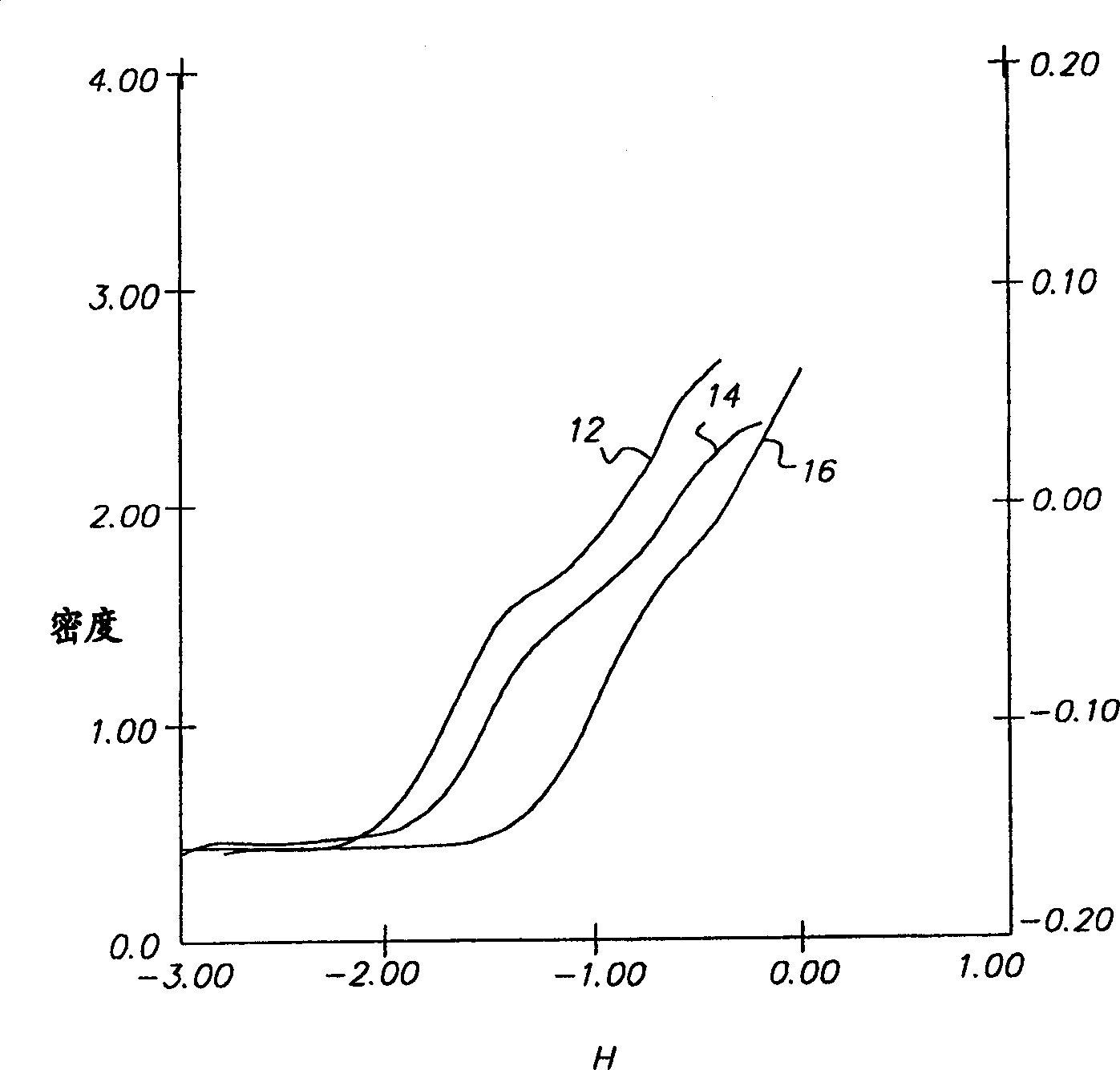

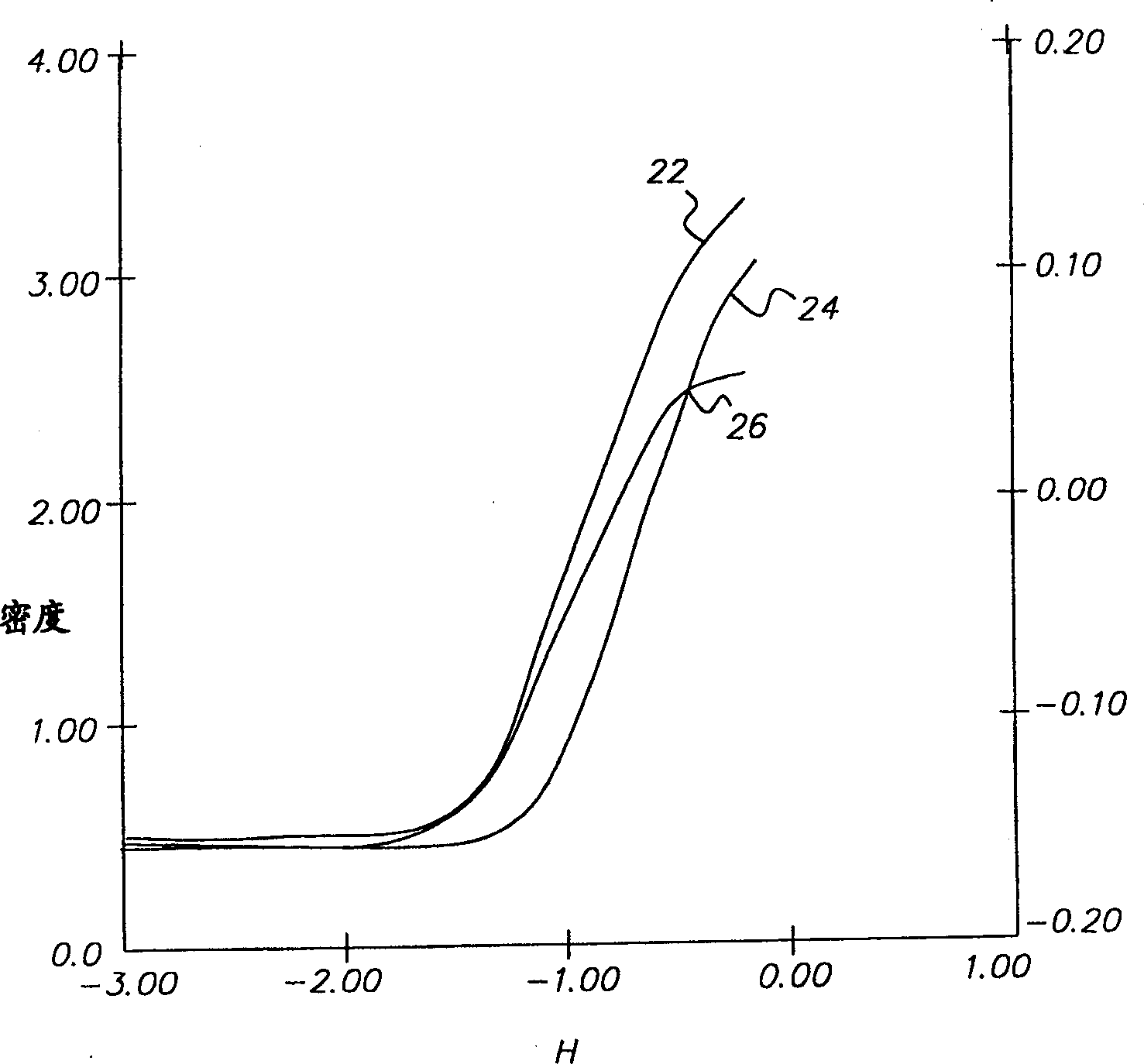

[0254] Coatings 2-1 to 2-6 were prepared, as listed in Table 5.

[0255] transform

2-1

2-2

2-3

2-4

2-5

2-6

illustrate

Compared

Compared

this invention

this invention

this invention

this invention

Front SOC

SOC-1

SOC-1

SOC-1

SOC-1

SOC-1

SOC-1

UV layer

UV-1

UV-1

UV-1

UV-1

UV-1

UV-1

red layer

RL-1

RL-1

RL-2

RL-2

RL-2

RL-2

UV intermediate layer

UV IL-1

UV IL-1

UV IL-1

UV IL-1

UV IL-1

UV IL-1

green layer

GL-1

GL-1

GL-2

GL-2

GL-2

GL-2

middle layer

IL-1

IL-1

IL-1

IL-1

IL-1

IL-1

SY-1

SY-1

SY-1

SY-1

SY-1

none

blue layer

BL-1

BL-1

BL-2

BL-2

BL-2

BL-3

Support

S-1

S-1

S-1

S-1

S-1

S-1

blue layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com