Quality design system used for cross-factory production organization

A quality design, factory production technology, applied in computing, data processing applications, resources, etc., can solve problems such as low review efficiency, failure to consider the interaction between upstream and downstream factory processes, and long time-consuming quality review meetings to achieve quality review results. Accurate, improve the efficiency of quality review, shorten the effect of quality review time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

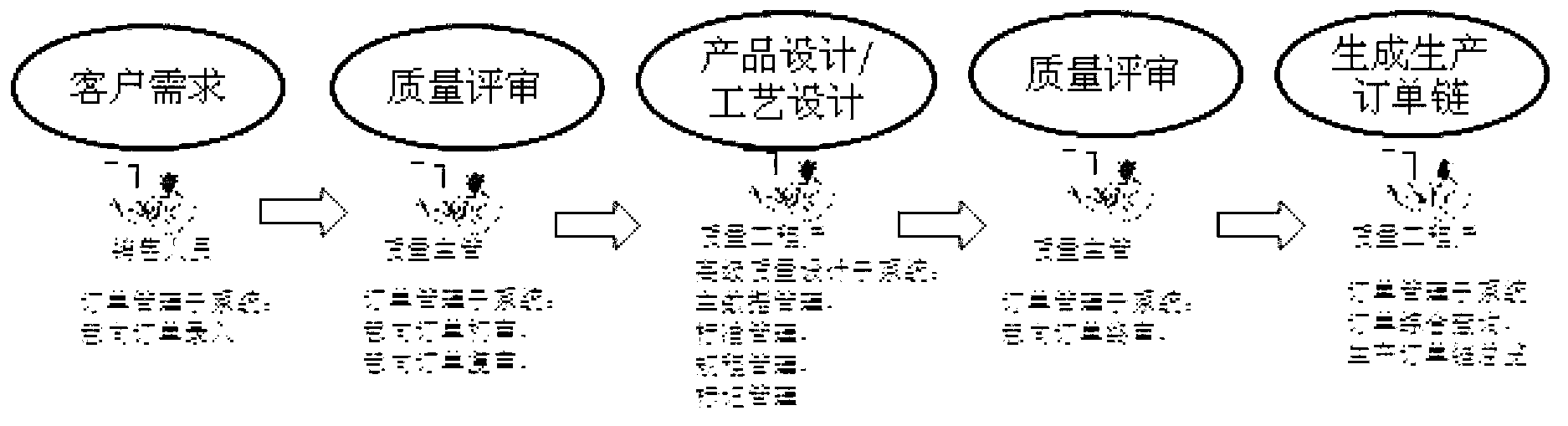

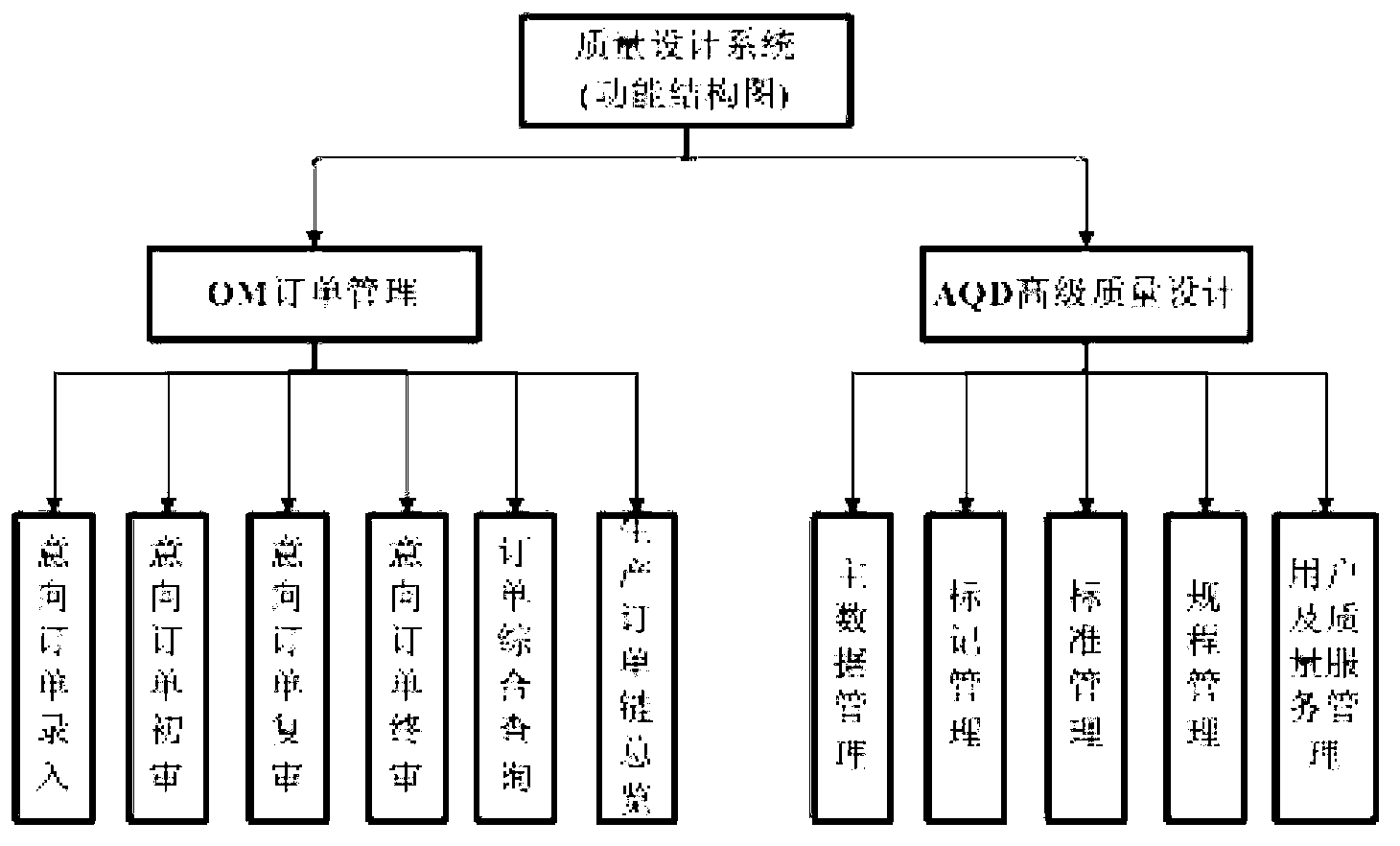

[0029] The present invention proposes a quality design method of cross-factory production organization based on tag chain technology, which is described in detail with examples as follows:

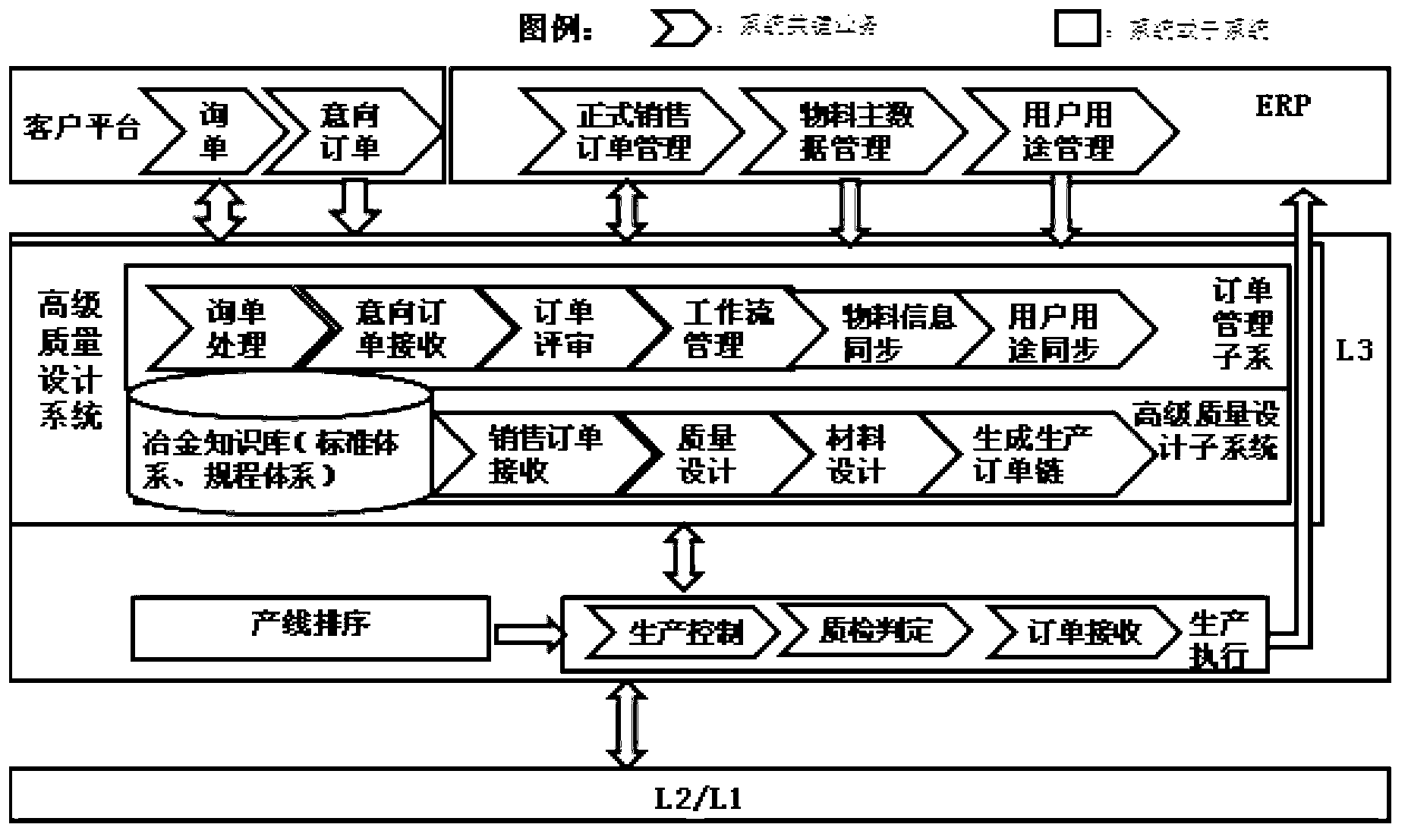

[0030] Such as figure 1 As shown, the quality design system receives inquiry requests or intended orders from the customer marketing platform, reviews the orders, and returns quality review results to the customer marketing platform; receives customer master data and formal sales orders from ERP, and uploads quality review results to ERP. Release the production order chain to the production line sorting, assign the judgment requirements and judgment standards to the production execution, receive the mark judgment request of the production execution, and send the mark judgment result to the production execution. Extract the data of customers, products, ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com