Underwater separation electrical connector assembly and its plug

A technology for electrical connectors and plugs, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problems that the reliability cannot be guaranteed, the short-circuit prevention of the plug and the socket, and the inconvenient unlocking and separation of the plug and the socket are not solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

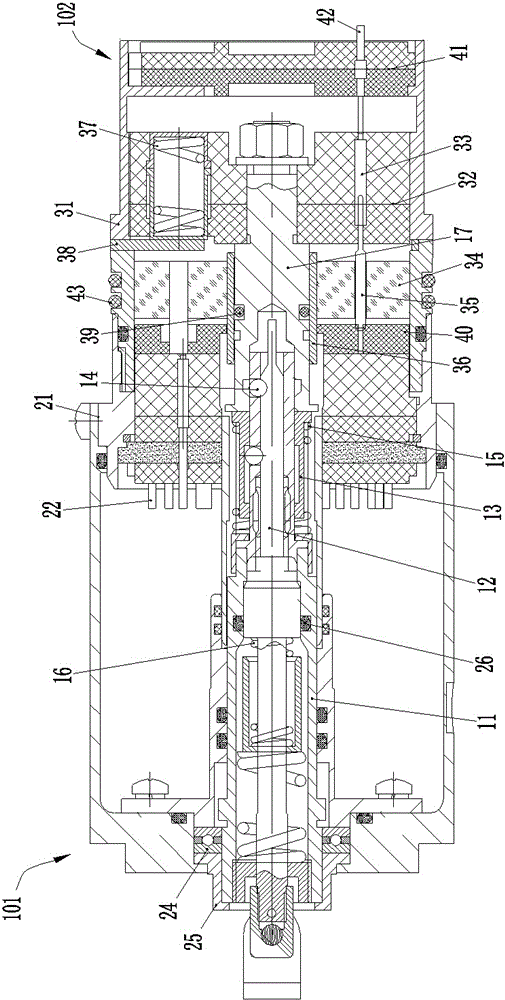

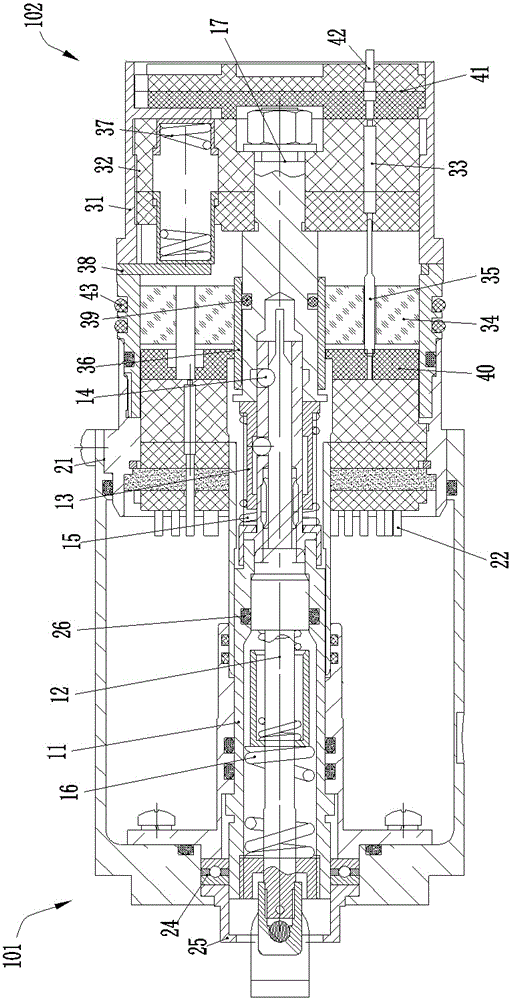

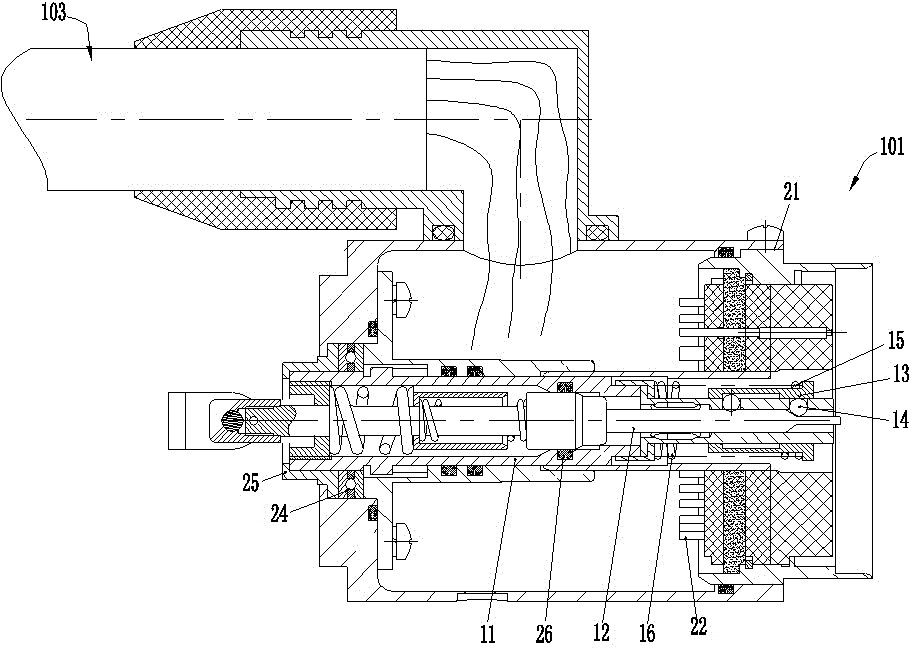

[0029] An embodiment of an underwater separation electrical connector assembly, such as Figure 1-7 As shown, a plug 101 and a socket 102 are included. A mandrel locking mechanism is provided between the plug 101 and the socket 102, and the mandrel locking mechanism includes a mandrel sleeve 11, a mandrel 12, a sliding sleeve 13, a steel ball 14, a pushing spring 15, a locking spring 16 and a lock. Tight circle 17.

[0030] The plug 101 takes the front end as the plug-in end, and it is connected with the corresponding underwater cable 103 during use, including the plug housing 21 and the plug contact 22, the mandrel sleeve 11 of the mandrel locking mechanism, the mandrel 12, the slide The sleeve 13 , the steel ball 14 , the pushing spring 15 and the locking spring 16 are located in the plug housing 21 , wherein the mandrel sleeve 11 can slide back and forth in the plug housing 21 . The plug housing 21 is also equipped with a rotating part (not shown in the figure), and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com