Low-voltage cable reel with embedded slip ring

A low-voltage cable and slip ring technology, which is applied in the field of cable retracting and unwinding equipment, can solve the problems of lack of phase, increase the volume of the reel, and heavy workload, and achieve simple and reasonable structure, reduce the volume of the reel, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

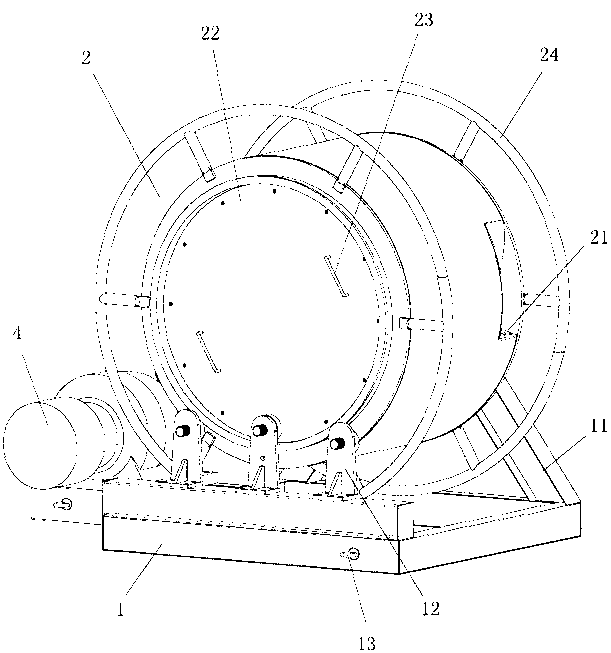

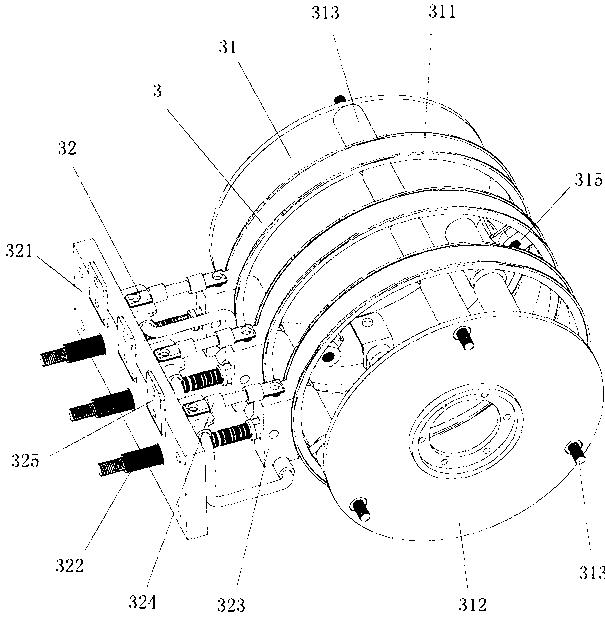

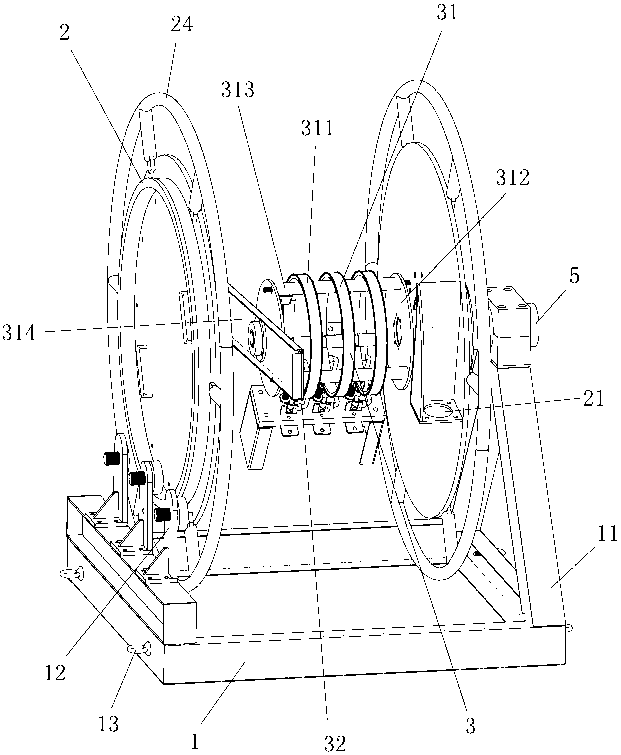

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a base 1, a cable winding bucket 2 arranged on the upper side of the base 1, a slip ring device 3, and a reel driving device 4 arranged on one side of the base 1, and cable retaining rings are arranged on both sides of the cable winding bucket 2 24. It can prevent the cable from falling off. The middle part of one side of the cable barrel 2 is supported on the inner end of the main shaft 5 through bearings and bearing discs (not shown in the figure), and the outer end of the main shaft 5 is supported on the top of the bracket 11 on the side of the base 1. The main shaft 5 It is a hollow structure, and the other side of the base 1 is provided with three winding auxiliary wheels 12 at intervals. It can be relatively rolled, and the three auxiliary wheels 12 of the reel are arranged one above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com