Turn-to-turn insulation structure of ultra-thin 10kV high-voltage motor and manufacturing method thereof

A technology of inter-turn insulation and high-voltage motors, which is applied to the shape/style/structure of winding insulation, insulated conductors, insulated cables, etc., which can solve the problems that the inter-turn insulation cannot be ultra-thin and the thickness cannot be reduced, so as to reduce insulation damage , Insulation damage reduction, damage rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

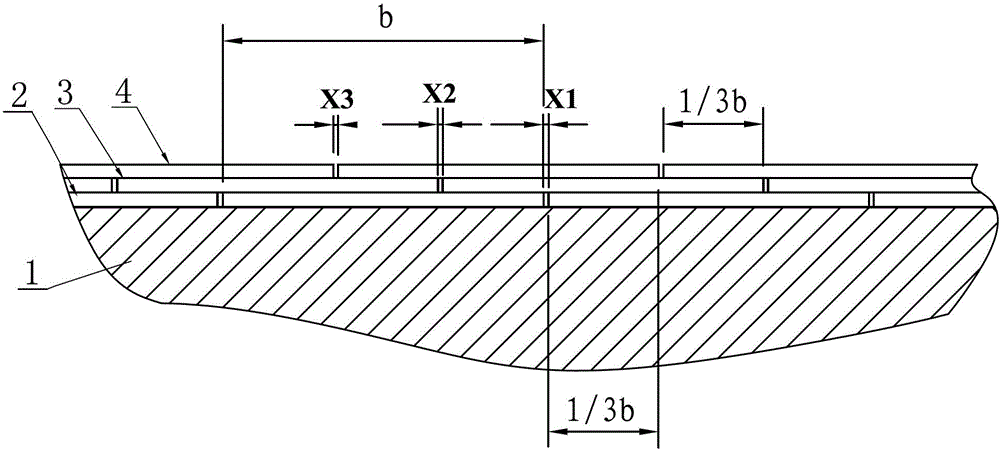

[0031] like figure 1 As shown, the present embodiment provides a turn-to-turn insulation structure of a 10kV class high-voltage motor, which includes a wire insulation layer, and the wire insulation layer is made of a three-layer polyester film less glue mica tape 2 wrapped on a copper flat wire conductor 1, 3,4 constitute.

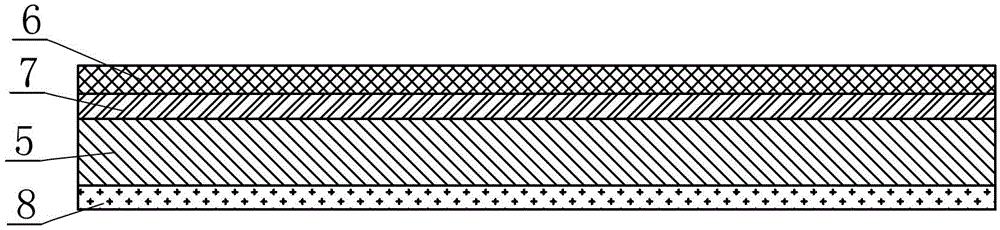

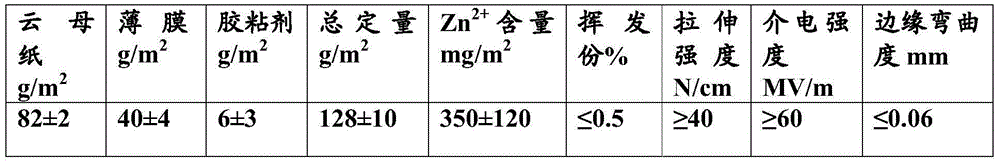

[0032] like figure 2 As shown, different from the polyester film less glue mica tape used in the traditional turn-to-turn insulation structure, the polyester film less glue mica tape 2, 3, and 4 used in this embodiment include polyester film layer 5, powder mica paper Layer 6, the adhesive layer 7 formed between the polyester film layer 5 and the powder mica paper layer 6, also includes a self-adhesive glue 8 coated on the reverse side of the polyester film layer 5. Controlling the content of self-adhesive 8 will not only help the discharge of gas and the infiltration of insulating resin during VPI of the motor, but also ensure the integrity of the ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com