Moving motor and electric vehicle

An electric motor and kinetic energy technology, applied in the field of electric motors and electric vehicles, can solve the problems of poor battery life, frequent charging, and limited number of electric vehicle charging stations, so as to save fuel, improve battery life, and avoid traffic accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

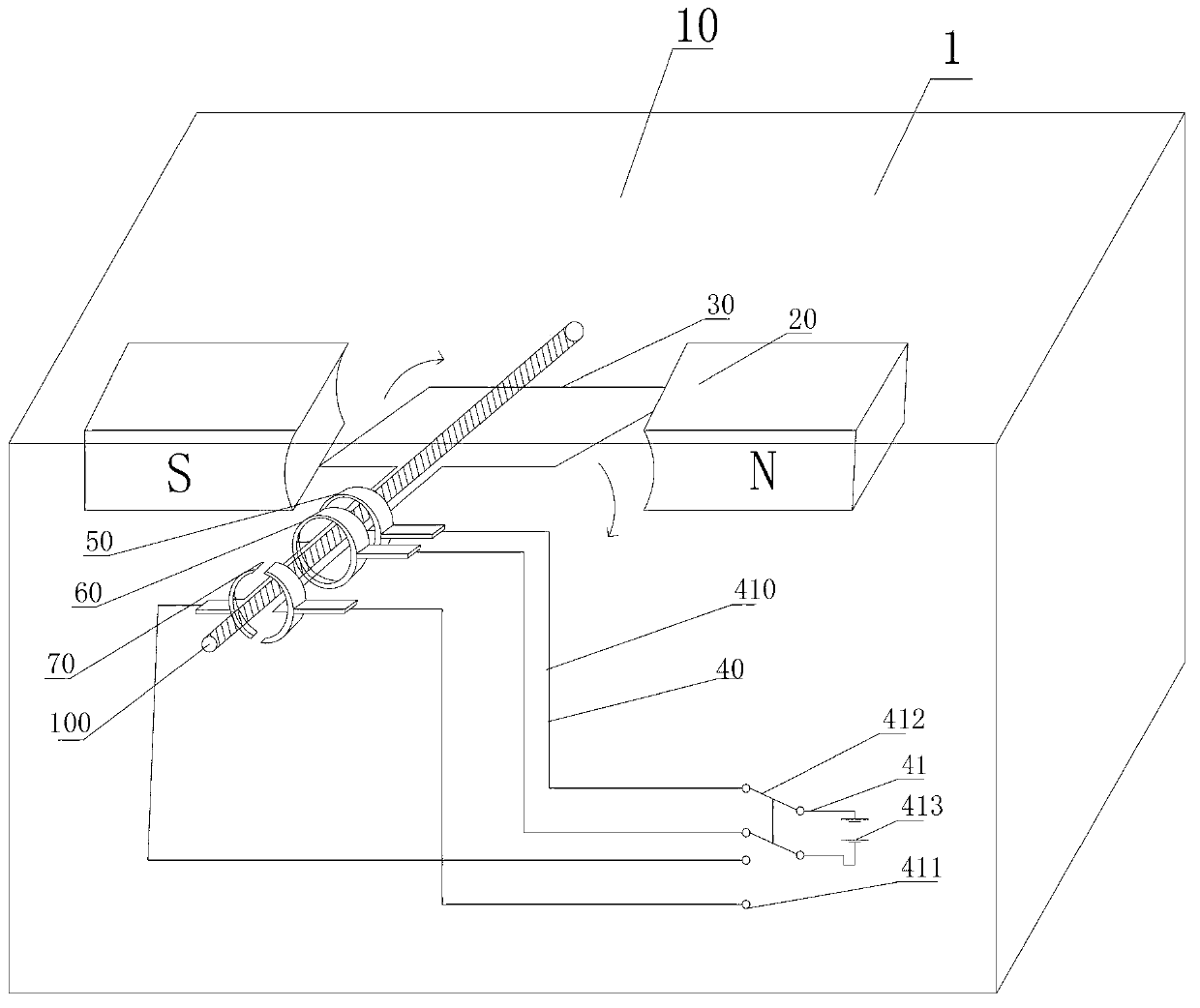

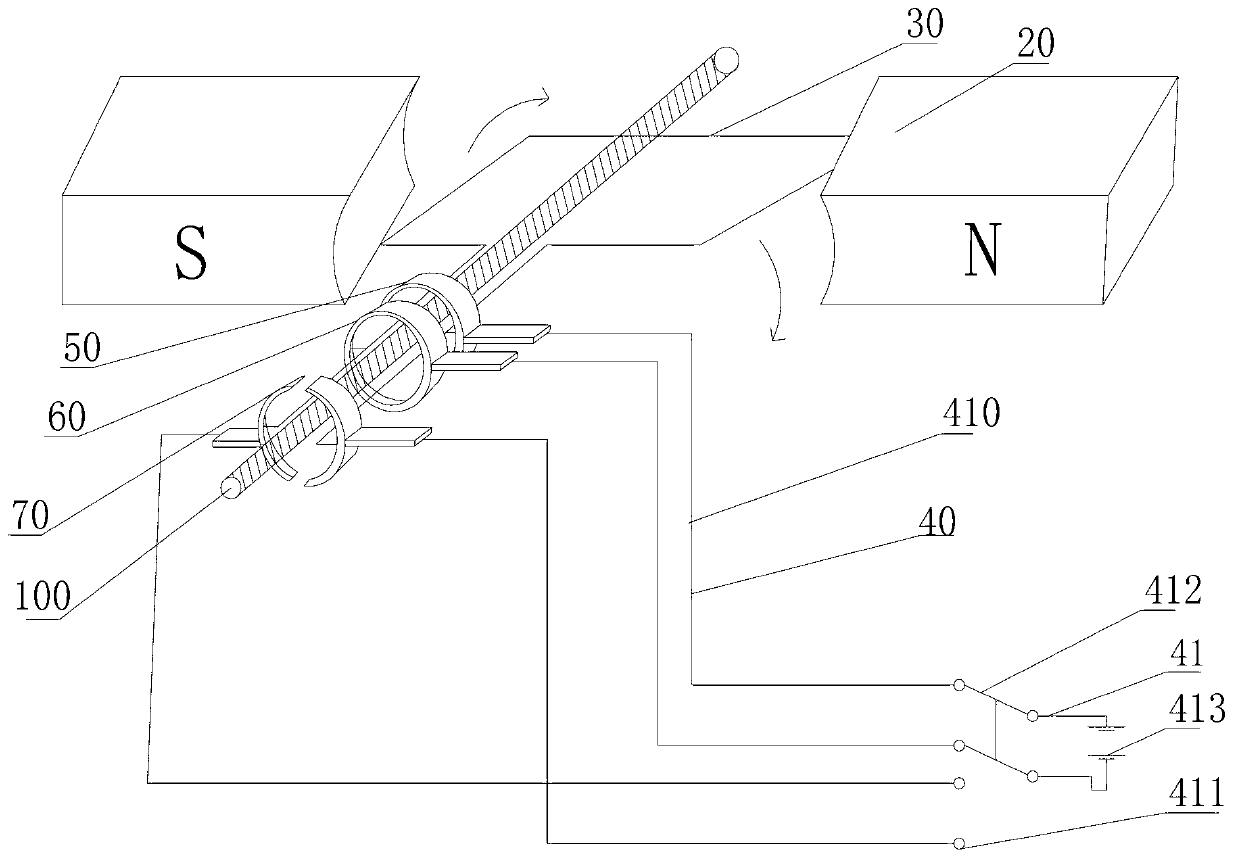

[0042] See figure 1 with figure 2 , The first embodiment of the present invention provides an electric motor 1, including a housing 10 and a magnetic field generator 20, a motor coil 30, a bidirectional control circuit 40, a first slip ring, and a carbon brush assembly 50 arranged inside the housing 10, The second slip ring and carbon brush assembly 60 and the third slip ring and carbon brush assembly 70;

[0043] Wherein, it should be noted that, as an implementation manner, the motor coil is a rectangular motor coil;

[0044] The magnetic field generating device 20 is used to generate a magnetic field effect;

[0045] The motor coil 30 is located between the N pole and the S pole of the magnetic field generating device 20;

[0046] The bidirectional control circuit 40 includes a main circuit 41 and a first branch 410 and a second branch 411 connected in parallel with each other; a bidirectional control switch 412 and a battery 413 are connected in series on the main circuit 41; th...

Embodiment approach

[0056] Preferably, as an implementable manner, the magnetic field generating device 20 includes a pair of permanent magnets;

[0057] The motor coil is located between the N pole of one permanent magnet in the pair of permanent magnets and the S pole of the opposite permanent magnet.

[0058] Preferably, as another possible implementation manner, the magnetic field generating device 20 includes an excitation winding through which an excitation current is passed.

[0059] The motor coil is located between the N pole and the S pole generated by the field winding.

[0060] Further, the electric motor 1 further includes a first voltage regulating device (not shown);

[0061] The first voltage regulating device is connected in series to the first branch 410;

[0062] The first voltage regulating device is used to adjust the output current of the first branch to adapt to the battery charging.

[0063] Further, the electric motor 1 further includes a second voltage regulating device (not shown);...

Embodiment 2

[0070] Correspondingly, on the basis of the electric motor provided in the first embodiment of the present invention, the second embodiment of the present invention also provides an electric vehicle, including a kinetic energy collection device and the above-mentioned electric motor;

[0071] The kinetic energy collection device includes a kinetic energy collection component and a transmission shaft;

[0072] The kinetic energy collection component is used to collect kinetic energy, and use the kinetic energy to drive the transmission shaft to rotate;

[0073] The transmission shaft is connected with a rotating shaft key on the moving motor.

[0074] Analyzing the structure of the above electric vehicle, it can be seen that when the power generation function is realized, the transmission shaft on the kinetic energy acquisition device drives (indirect drive) the rotating shaft to rotate to realize power generation and charge the battery on the power generation branch; when the motor fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com