No-seed box no-seeding unit hill planter

A technology of seed metering device and hole sowing machine, which is applied in the field of agricultural machinery, can solve problems such as uneven time distribution, labor, holes, lack of seedlings and ridges, etc., achieves strong consistency between individuals and groups, improves comprehensive economic benefits, and The effect of little environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

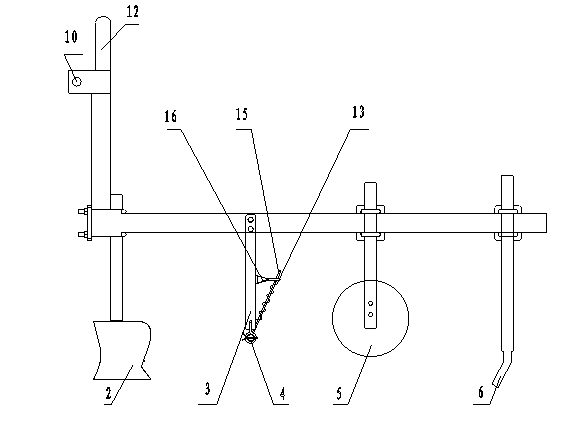

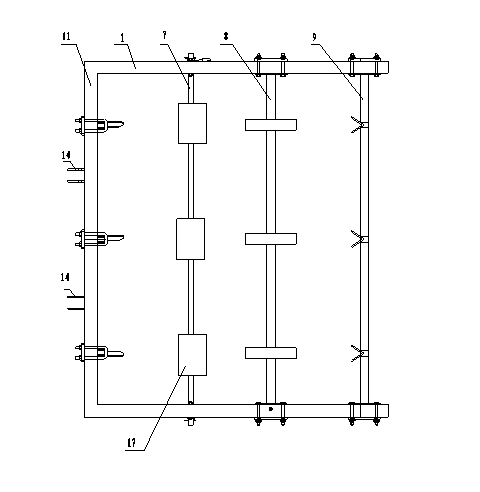

[0020] exist Figure 1~2 In the example shown in, comprise frame 1, ditch opener 2, strip seed bar 7, compaction wheel 5, cover soil shovel 6, wherein be provided with three-point suspension point on frame 1, horizontal traction suspension point 14 is set On the horizontal traction beam 11 of the frame 1, the lifting suspension point 10 is set on the vertical hanging beam 12 of the frame 1. Before operation, according to the number of sowing rows of the machine, determine that the strip seed roll 17 is loaded into the strip seed bar The number of 8, because the side plate 3 is fixedly connected with the frame 1, the suspension ring 4 is hinged with the side plate 3, the suspension ring 4 is fixedly connected with the connecting rod 15, and the connecting rod 15 runs through the spring 13 and the support plate 16 successively, and the support plate 16 is in addition One end is fixedly connected with the side plate 3, the spring 13 is located between the support plate 16 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com