Oat shelling device

An oat and device pair technology is applied in the field of oat hulling devices, which can solve the problems of nutrient loss, unsuitability for preservation, and short shelf life of oat granules, and achieves the effects of high space utilization, retention of nutritional value, and guaranteed preservation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

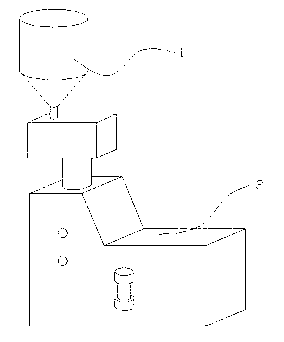

[0014] Such as figure 1 As shown, a kind of oat shelling device, comprises particle selection device 1, particle removal device 2, watering device 3, infrared enzyme inactivation device 4, and described particle selection device 1 is used as raw material oat grains to be selected , to remove oats with incomplete or smaller particles; the particle shelling device 2 receives the oat particles delivered by the particle selection device, and performs shelling treatment on the oat particles; The oat granules are sprayed with water; the infrared enzyme inactivating device 4 is irradiated with infrared rays on the oat granules after water spraying, and dried, and the particle selection device 1 is provided with a vibrating device, and a vibrating device is provided at the vibrating device. Screen selection, the particle selection device 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com