Preparation method of preserved meat product and self-heating food

A product and bacon technology, which is applied in the field of meat product processing, can solve the problems affecting the anti-corrosion preservation ability of products, shortened storage period, product water retention, texture and flavor deterioration, etc., so as to shorten the production cycle and reduce the generation of harmful substances. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

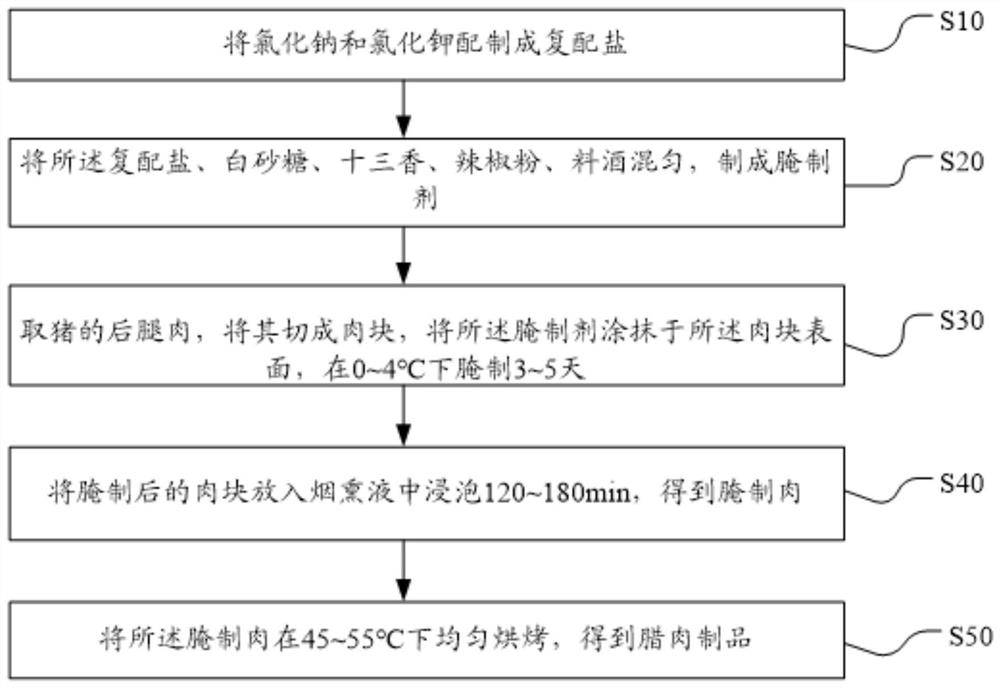

[0030] see figure 1 , the preparation method of the bacon product comprises the following steps:

[0031] Step S10, preparing sodium chloride and potassium chloride into compound salt.

[0032] The sodium content of bacon products currently on the market is generally high, which does not meet the modern consumers' pursuit of a healthy diet. In this example, the food-grade sodium and potassium compound salt was used instead of the traditional single-used sodium salt. On the premise of maintaining the original quality of meat products, the sodium salt content in the product was reduced, and the potassium ion content was appropriately increased. Some characteristic consumer groups provide more healthy and delicious new bacon products. After a lot of theoretical and experimental verification, in the present embodiment, in the compound salt, the mass ratio of the sodium chloride to the potassium chloride is (6-8): (2-3.5), so, the compound salt The sodium content in the mixed sa...

Embodiment 1

[0054] The preparation of embodiment 1 bacon products

[0055] (1) Prepare food-grade sodium chloride and potassium chloride in a mass ratio of 7:3 to make compound salt.

[0056] (2) Preparation of marinade: mix compound salt, white sugar, thirteen spices, chili powder, and cooking wine in a mass ratio of 3:4:0.4:0.8:0.4.

[0057] (3) Choose pork hind legs that have passed the health inspection, first remove the fascia on the surface of the pig hind legs, and then cut them into pieces of meat with a weight of about 150-200g (for every 100g of meat, add 8.6g of marinated salt), and the length of the meat piece is 18-22cm, the width is 2-5cm, and the thickness is 1-1.5cm, and then the pickle agent is evenly applied to the surface of the meat piece, and marinated at 0°C for 4 days.

[0058] (4) Soak the marinated meat pieces in smoked liquid (for every 100 g of meat pieces, add 4 g of smoked liquid) for 150 min to obtain smoked meat.

[0059] (5) The smoked meat is evenly roas...

Embodiment 2

[0060] The preparation of embodiment 2 bacon products

[0061] (1) Food-grade sodium chloride and potassium chloride are formulated into compound salt at a mass ratio of 6.5:3.5.

[0062] (2) Preparation of marinade: mix compound salt, white sugar, thirteen spices, chili powder, and cooking wine in a mass ratio of 4:3:0.3:1:0.5.

[0063] (3) Choose pork hind legs that have passed the health inspection, first remove the fascia on the surface of the pig hind legs, and then cut them into pieces of meat with a weight of about 150-200g (for every 100g of meat, add 8.8g of marinated salt), and the length of the meat piece is 18-22cm, the width is 2-5cm, and the thickness is 1-1.5cm, and then the pickle agent is evenly applied to the surface of the meat piece, and marinated at 0°C for 4 days.

[0064] (4) Soak the marinated meat pieces in smoked liquid (adding 3 g of smoked liquid for every 100 g of meat pieces) for 180 min to obtain smoked meat.

[0065] (5) Evenly bake the smoked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com