Anti-jamming grate-bar slide screen

A technology of grate bar and sliding screen is applied in the field of material screening equipment, which can solve the problems of large space occupation and serious material jamming, and achieve the effect of small space occupation and low maintenance rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

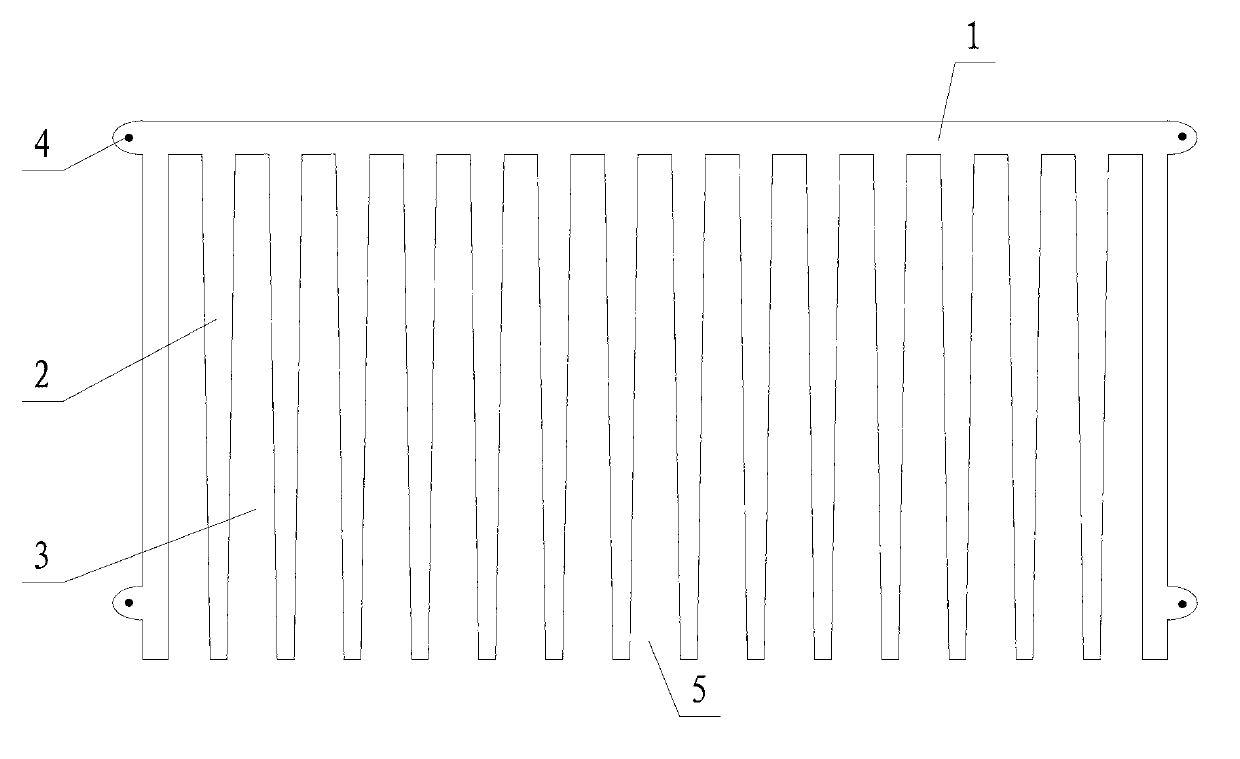

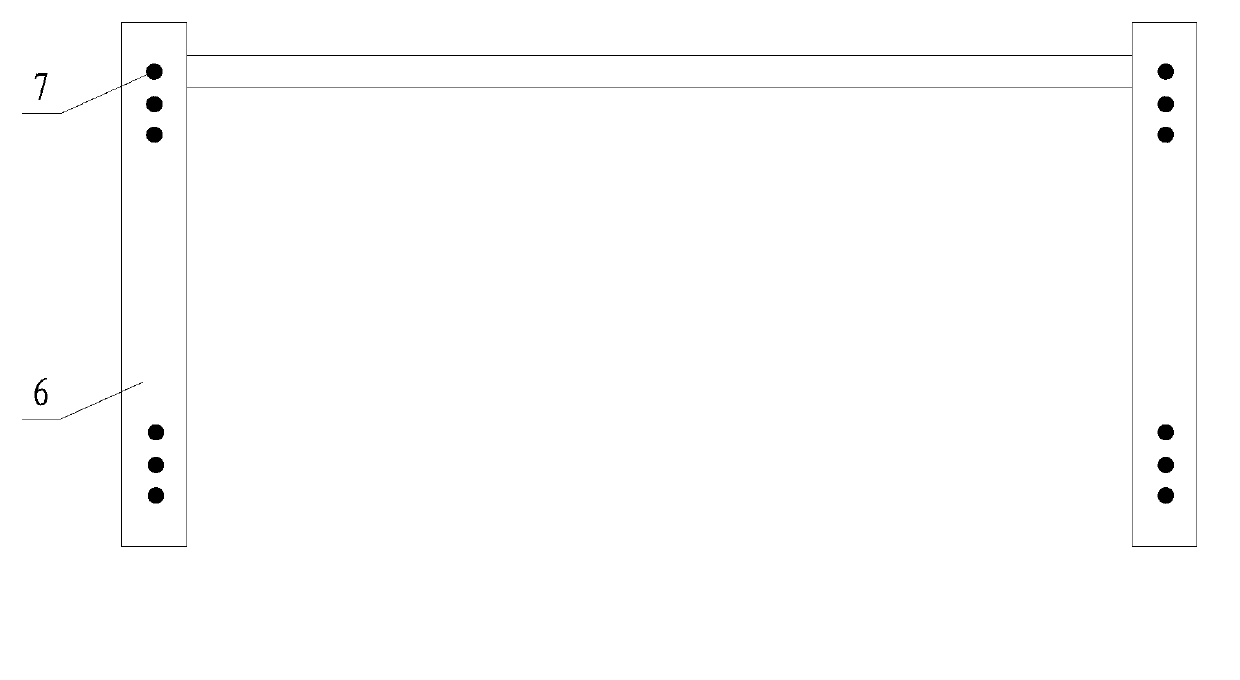

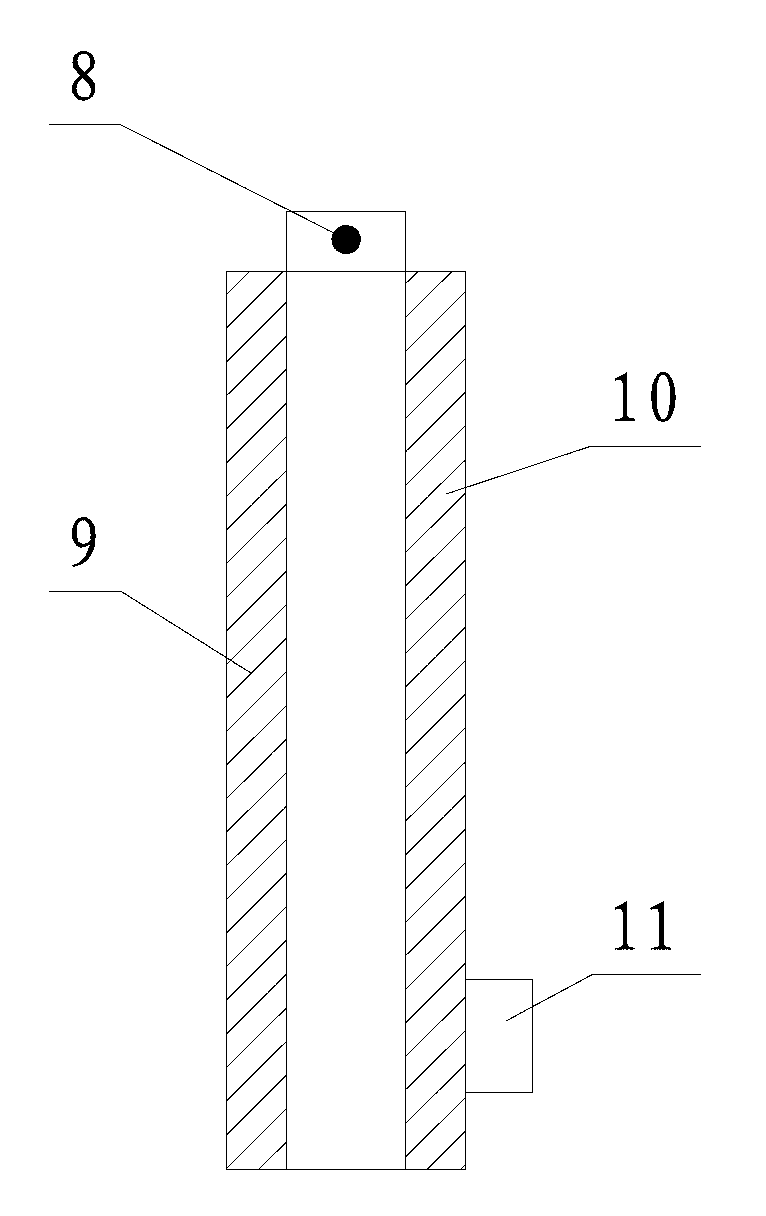

[0023] like figure 1 As shown in the figure, the anti-jamming grate sliding screen of the present invention is the sieve plate 1, the two sides of the sieve plate 1 are respectively provided with fixing ears 4, and the sieve plate 1 is fixed on the external fixture through the fixing ears 4 on both sides; The plate 1 is inclined to the horizontal plane along the sliding direction of the material, and the inclined angle is 15°~60°. By adjusting the inclined angle of the screen plate 1, the passing rate of the material can be increased or decreased. The larger the inclined angle is, the screening passes The rate is low, on the contrary, the smaller the angle of inclination is, the larger the screening pass rate is. One end of the sieve plate 1 is located below the feed port 12, and the other end is the discharge port 5; the sieve plate 1 is provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com