Automatic cleaning device for blowout preventer

An automatic cleaning and blowout preventer technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of difficult manual cleaning, low cleaning efficiency, waste of energy, etc., and save manpower Reduce the labor intensity of resources and employees, achieve recycling, and improve the management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

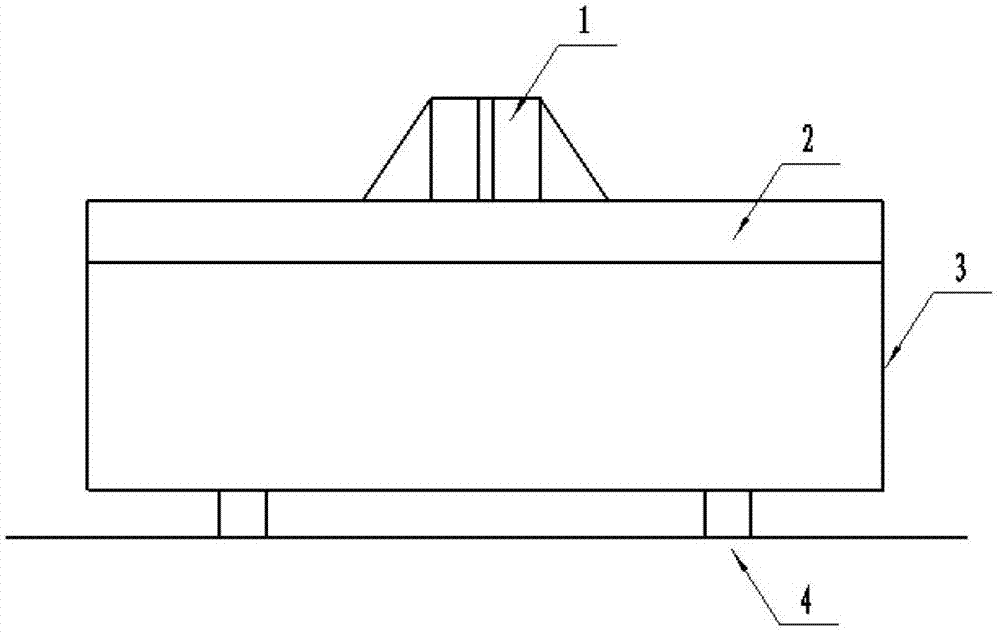

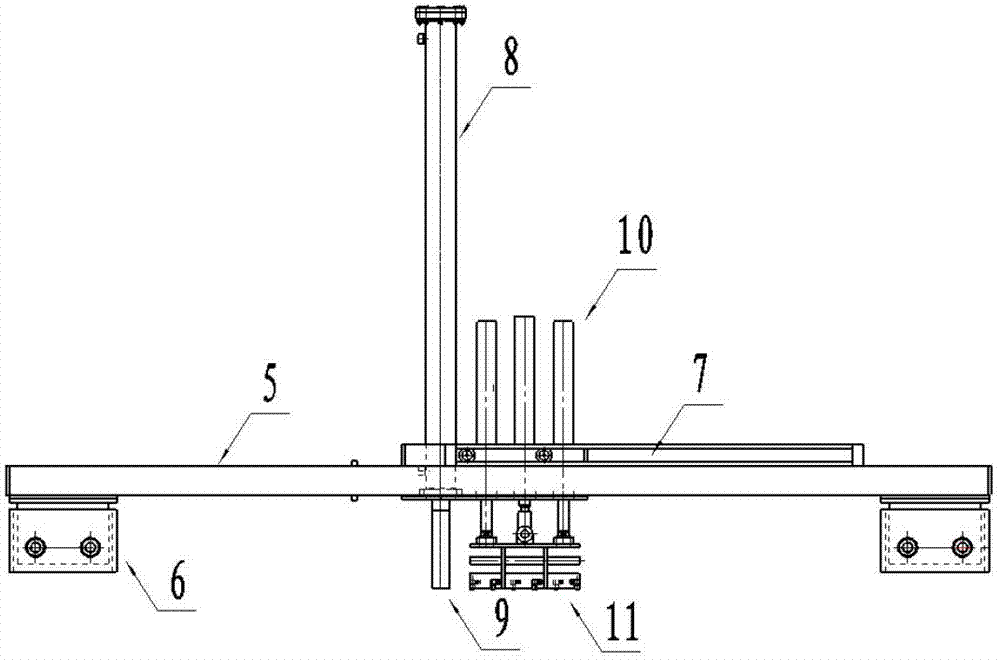

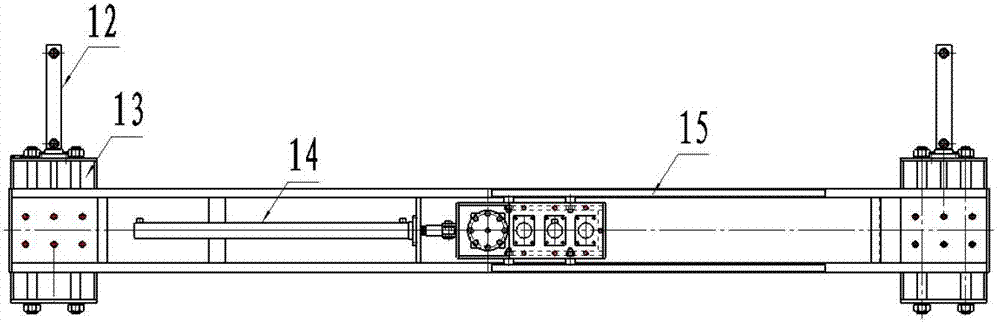

[0016] The present invention will be further described below in conjunction with the accompanying drawings: BOP automatic cleaning device, which consists of a centering device (1), an automatic rotating turntable (2), a mine car body (3), a beam main frame (5), an inner Cavity telescopic oil cylinder (8), inner cavity cleaning nozzle (9), top cleaning nozzle (11), top lateral moving oil cylinder (12), cleaning nozzle (18), upper and lower movable guide rails (19), primary sedimentation tank (21) , a water pump (23), and a purification tank (26). The BOP guiding centering device (1) is welded at the center of the automatic rotating turntable (2), the automatic rotating turntable (2) is installed on the mine car body (3), and the turntable (2) is on the mine car body (3) The upper part rotates freely, and the wheel hub (4) is installed under the mine car body (3), which drives the whole mine car to move back and forth on the track. Hang the blowout preventer on the mine car bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com