Forming method of aluminum extrusion

An aluminum extrusion and finished product technology, which is applied in the control equipment of metal extrusion, metal extrusion, manufacturing tools, etc., can solve the problems of different extrusion products, large energy loss, and limitation of the width-thickness ratio of aluminum extrusion products. Achieve the effect of energy use and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

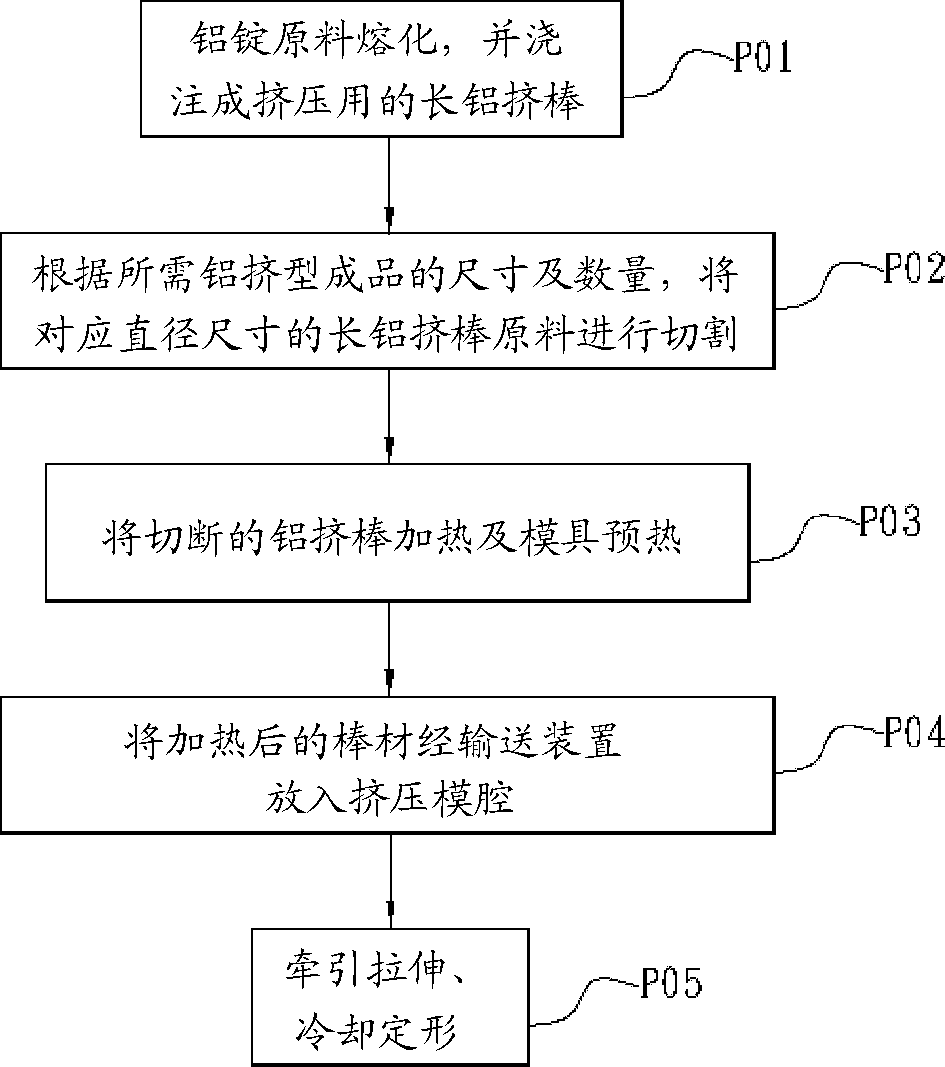

[0031] A method for forming an aluminum extrusion profile according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

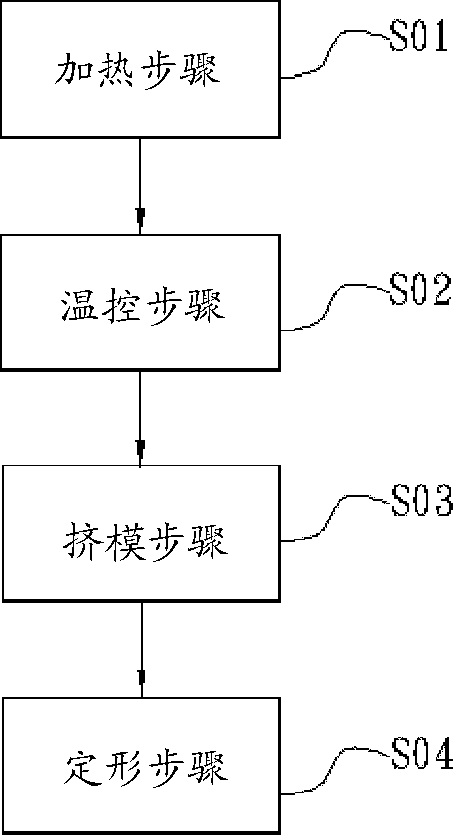

[0032] Please refer to figure 2 As shown, it is a flow chart of an aluminum extrusion forming method in a preferred embodiment of the present invention.

[0033] The forming method of aluminum extrusion includes a heating step S01, a temperature control step S02, an extrusion step S03 and a shaping step S04.

[0034] The heating step S01 is to heat the raw material, for example, put the raw material into a crucible and heat it with a cycle induction over 640 degrees to make it into a molten superheated melt. Among them, the composition of the aluminum alloy can be adjusted through the heating process. The raw material can be, for example, aluminum metal, aluminum alloy, or metal matrix composite (MMC) based on aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com