A super high speed air bearing electric spindle

A technology of air bearing and electric spindle, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that the coolant cannot reach smoothly, and achieve weight reduction, high rotation accuracy, and improved support. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

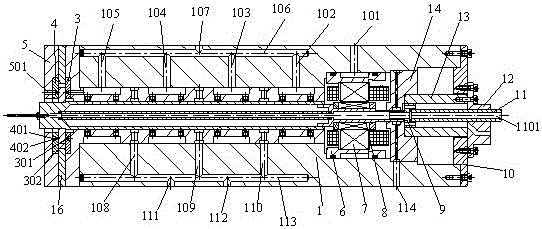

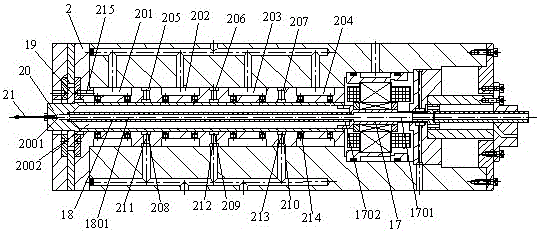

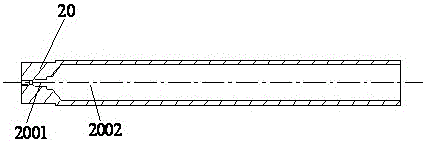

[0019] Such as figure 1 Shown is a schematic diagram of an ultra-high-speed air bearing electric spindle, mainly including: housing 1, static pressure radial air bearing 2, a pair of closed static pressure thrust air bearings (rear thrust bearing 3 and front thrust bearing 4) , the rotor 20, the motor assembly and the gas sealing device at the motor end. The rotor 20 is a thin-walled hollow rotor with stepped through-holes in the center, including a large through-hole 2002 and a small through-hole 2001 , and the connection between the large through-hole 2002 and the small through-hole 2001 is a tapered surface. The large through hole 2002 of the rotor 20 is equipped with an elongated hollow tube 18 inside, and the elongated hollow tube 18 is provided with a central through hole 1801 . One end of the elongated hollow tube 18 is installed on the transition cone surface of the large through hole 2002 and the small through hole 2001, and is sealed with a sealing ring, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com