Bicycle transmission speed changing mechanism

A speed change mechanism and bicycle technology, which is applied in the direction of vehicle gearboxes, wheel transmissions, vehicle components, etc., can solve the problems of no formation, loss of functions, inconsistent work directions of spiral bevel gears, etc., and increase the meshing contact surface of the gears , Improve the function utilization rate, enhance the transmission efficiency and the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings of the description.

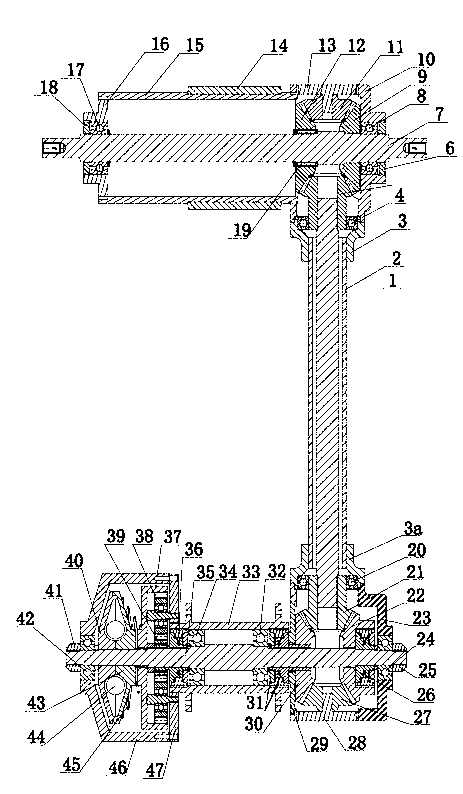

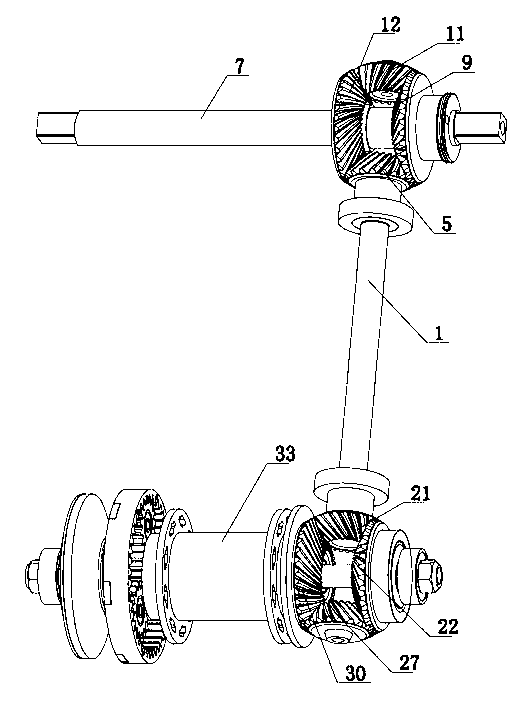

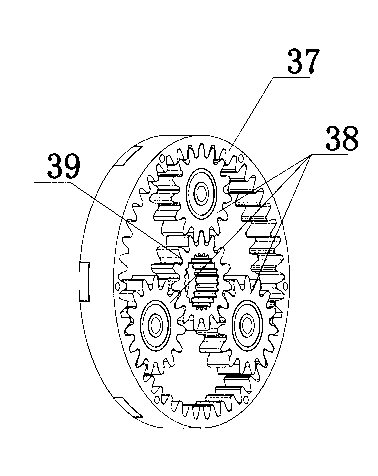

[0021] As shown in the figure, the bicycle transmission speed change mechanism includes a driving shaft 7 connected to two pedals, a driven shaft 1 connected to the rear wheel of the bicycle, a first driving wheel 9 is fixedly installed on the driving shaft 7, and the first driving wheel 9 is connected to the second driving wheel. A driven wheel 5, the first driven wheel 12, and the first booster wheel 11 are meshed with each other to form the first group of zigzag gear sets. The first driven wheel 5 is fixedly installed on the driven shaft 1, and the first driven wheel 12 and the driving shaft 7 Rotate and fit, the first power-assisted wheel 11 is installed on the bicycle frame; The power-assisted wheels 30 intermesh and drive to form the second group of zigzag gear sets. The second driven wheel 22 is fixedly connected with the rear rotating shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com