Split type chain piece used for pipe-chain type powder conveyor

A split-type conveyor technology, applied in conveyors, transportation and packaging, etc., can solve labor-intensive and time-consuming problems, achieve the effect of simple operation and broaden the application coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

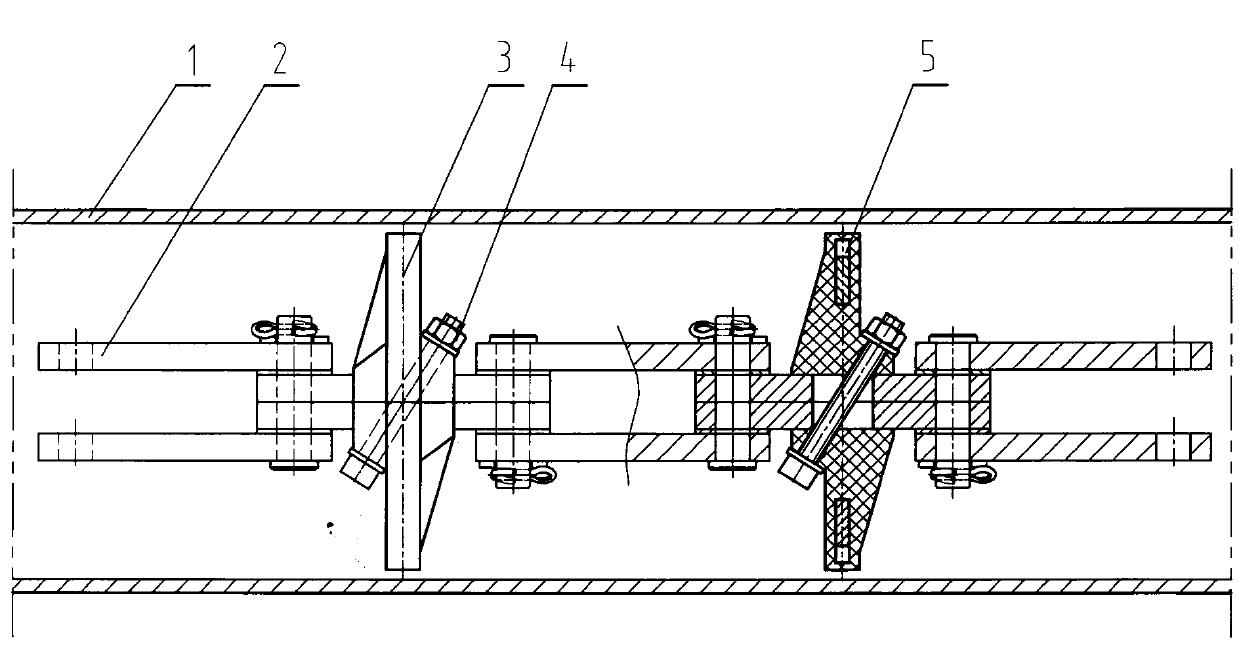

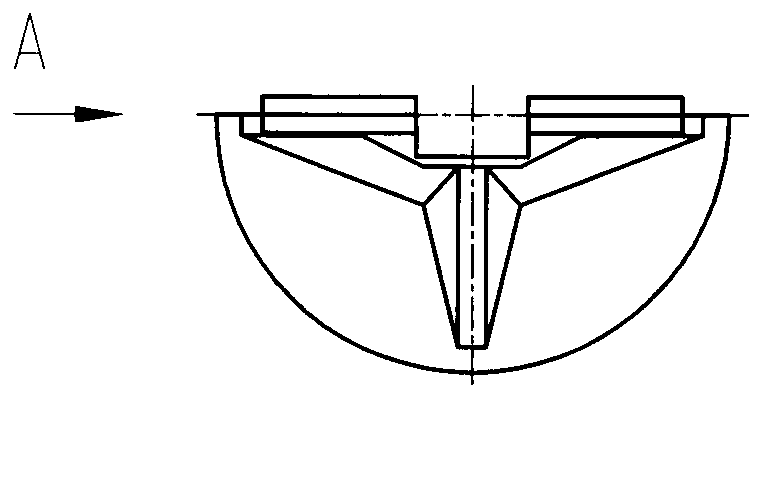

[0022] see figure 1 , figure 2 and Figure 8 , use bolts and nuts (4) to connect 2 pieces of split-type composite chain pieces (3) used for pipe chain powder conveyors to the chain (2) through the positioning and connection waist hole in the middle of the inner chain link (8) on the inside link (8).

Embodiment 2

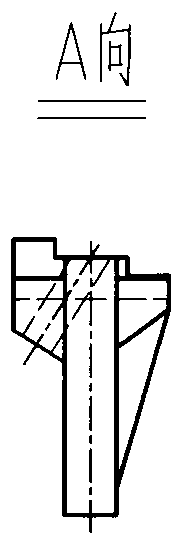

[0024] see Figure 4 , Figure 5 , Figure 8 and Figure 9 , use bolts and nuts (4) to pass through the positioning and connection waist holes in the middle of the inner chain link (8), connect the two split metal chain pieces (6) to the inner chain link (8) of the chain (2), connect When adding a positioning washer (7) between the metal chain piece (6) and the inner chain link (8), the tongue-shaped head of the positioning washer (7) is embedded in the middle of the inner chain link (8) for positioning and connection Waist hole, the effect of locating spacer (7) is to guarantee the accurate location of chain plate and prevent chain plate from taking place front and back, left and right displacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com