Fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device and method by methane vapor reforming

A technology for producing hydrogen from methane steam and reforming, which is applied in the fields of chemical industry, oil refining, and energy, can solve the problems of easy deactivation of catalysts at high temperature, reduce the loss of catalyst activity and service life, and reduce the possibility of entering the high-temperature regeneration zone. Avoid the effect of heating up energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

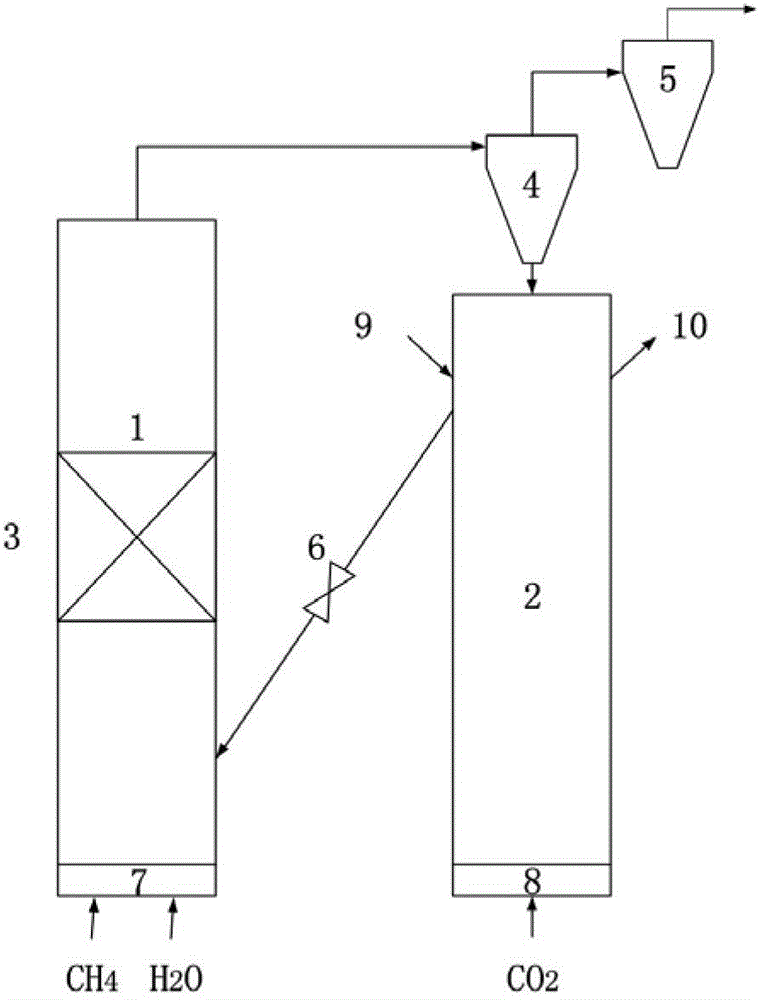

[0042] use as figure 1 In the device for hydrogen production by adsorption-enhanced steam reforming of methane, the fluidized-fixed composite bed reactor 1 adopts a riser reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

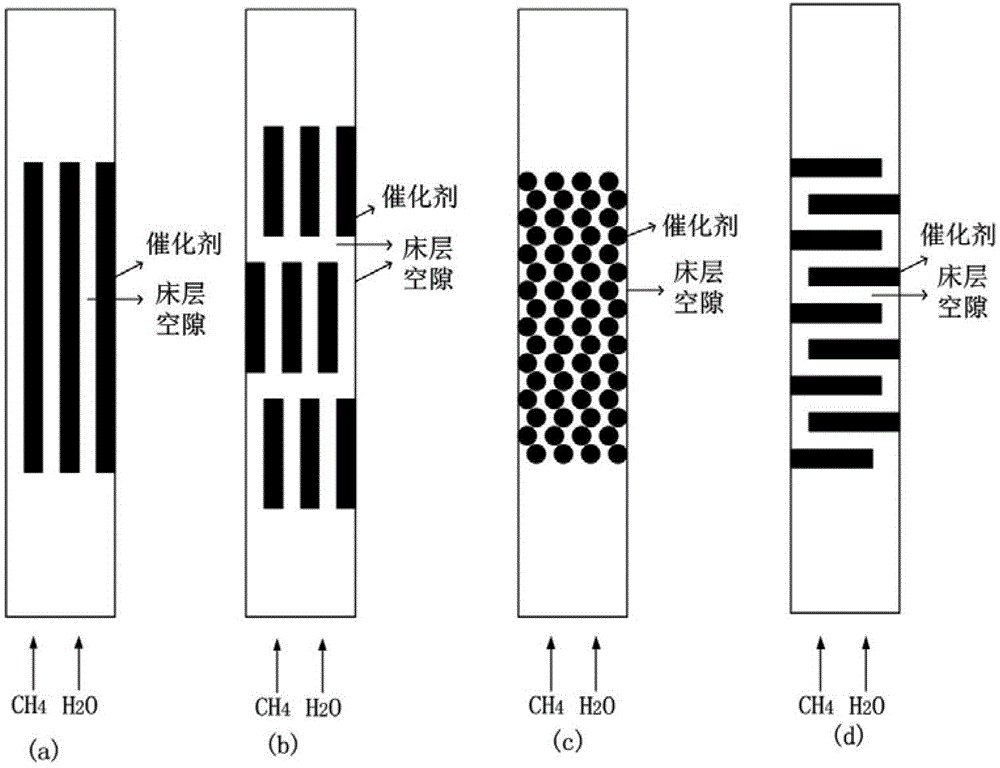

[0043] Nano-CaO-based CO 2 Adsorbent microspheres: the bulk density is 0.8g / cm 3 , the average particle size is 5 microns, and the amount of adsorbent is 3000g. riser reactor press figure 2 (a) is filled with a nickel-based catalyst, the catalyst is a Raschig ring with a diameter of 10mm and a length of 6mm, and a bulk density of 1.5g / cm 3 , catalyst consumption 1500g, bed porosity 0.4.

[0044] The operation steps are as follows:

[0045] (1) Pass the preheated mixture of water vapor and methane into the riser reactor 1, drive the adsorbent on the first gas distributor 7, and contact the catalyst 3 filled in the middle of the riser reactor. Adsorption enhanced reforming reaction; wherein the molar ratio of water...

Embodiment 2

[0051] use as figure 1 The shown adsorption enhanced methane steam reforming hydrogen production reaction device, the fluidized-fixed composite bed reactor 1 adopts a riser reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

[0052] Nano-CaO-based CO 2 Adsorbent microspheres: bulk density 0.8g / cm 3 , the average particle size is 100 microns, and the amount of adsorbent is 3000g. Nickel-based catalyst packed in riser reactor: according to figure 2 As shown in (b) filled with catalyst, the catalyst is a cylinder with a diameter of 10mm and a length of 6mm, with a solid density of 2g / cm 3 , catalyst consumption 1500g, bed porosity 0.7.

[0053] The specific operation steps are the same as in Example 1, wherein the mol ratio of water vapor and methane is 2:1, and the methane flow rate is 12L / min, the gas velocity of the riser reactor is 0.6m / s, and the temperature of the riser reactor is 650 °C, the regeneration temperature is 800°C, the...

Embodiment 3

[0056] use as figure 1 The shown adsorption enhanced methane steam reforming hydrogen production reaction device, the fluidized-fixed composite bed reactor 1 adopts a fluidized bed reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

[0057] Nano-CaO-based CO 2 Adsorbent microspheres, bulk density 0.8g / cm 3 , the average particle size is 20 microns, and the amount of adsorbent is 3000g. Nickel-based catalyst packed in fluidized bed reactor: according to figure 2 (c) shown in the filling, the shape is a seven-hole sphere, the particle size is 16mm, and the solid density is 2g / cm 3 , catalyst consumption 1500g, bed porosity 0.5.

[0058] The specific operation steps are the same as in Example 1, wherein the mol ratio of water vapor and methane is 6:1, and the methane flow rate is 15L / min, the fluidized bed reactor gas velocity is 3m / s, and the fluidized bed reactor The temperature is 600°C, the regeneration temperature is 800°C, the reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com