Integrated assembled concrete frame and shear wall connection structure and construction method thereof

A technology for connecting structures and construction methods, applied in the direction of walls, building components, building structures, etc., can solve the problems of high installation accuracy, alignment of upper and lower steel bars, and a large number of steel sleeves, and achieves good seismic performance, Reasonable stress and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

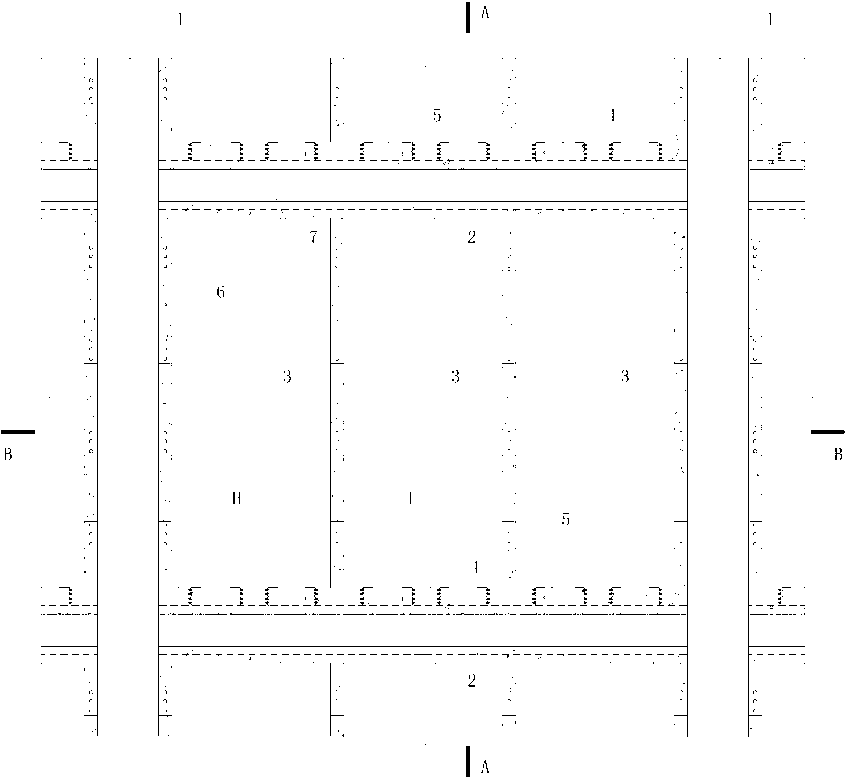

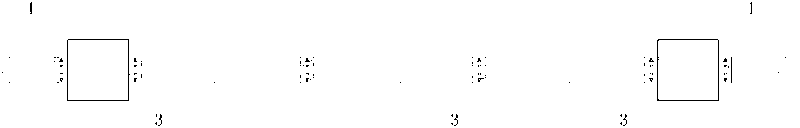

[0029] Embodiment: The assembled integral concrete frame-shear wall connection structure of this implementation is as follows figure 1 , figure 2 and image 3 As shown, it includes a column 1 prefabricated by concrete, a composite beam 2 and a shear wall 3, the column 1 and the shear wall 3 are connected end to end in the horizontal direction, and the top of the shear wall 3 is installed with a composite beam 2 , the laminated beam 2 is lapped with a floor 4 , and the connection interface of the above-mentioned components is filled with post-cast concrete 5 .

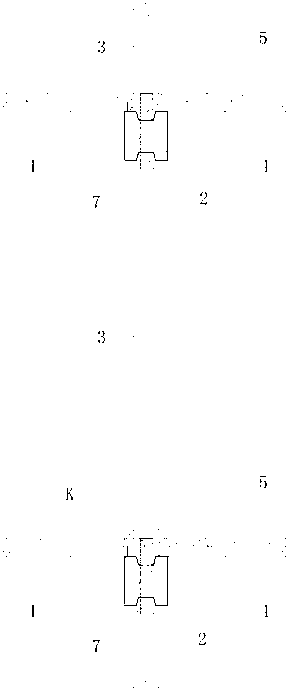

[0030] Such as Figure 4 and Figure 7 As shown, a bolt sleeve 10 is pre-embedded on the side wall of the column 1 at the junction of the column 1 and the shear wall 3, and the ∏-shaped groove 6 is installed on the bolt sleeve 10 through the opening on the bottom wall and the fixing bolt 9 , There are oval bolt holes on the opposite side walls of the Π-shaped groove 6 .

[0031] Such as Figure 5 As shown, at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com