Concrete compound self-heat-preservation building block and manufacturing process thereof

A technology of self-insulation block and manufacturing process, which is applied in the direction of building structure, building components, construction, etc., can solve the problems of thermal insulation and sound insulation, poor load-bearing performance of blocks, high production cost, etc., and achieve remarkable technical effects , good load-bearing performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

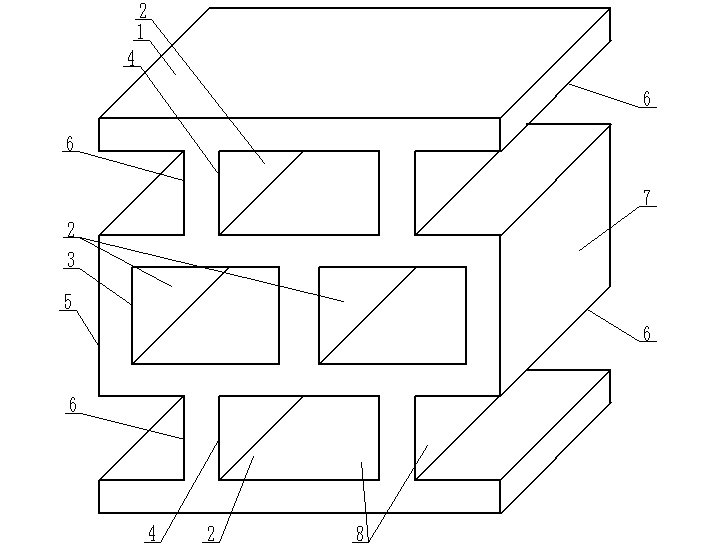

Image

Examples

Embodiment 1

[0030] The manufacturing process of concrete composite self-insulation block, it comprises the following steps:

[0031] S1. Material preparation: Prepare materials according to the following materials and their weight ratios: cement: 30; fly ash: 10; waste residue: 50; water: 10;

[0032] S2. Mixing and stirring: put the above-mentioned waste slag into the batching bin according to the proportion, and send the prepared mixture into the mixer through the conveyor for stirring. After 5 minutes, add the cement, fly ash and water in the above proportion to carry out Stir fully, release the mixture after 9 minutes;

[0033] S3. Block forming: send the released mixture into the block forming machine through the conveyor, distribute the material in batches through the distributing machine, complete the block forming through the forming mold, and make a multi-hole block;

[0034] S4. One-time curing of blocks: Send the formed blocks together with the supporting plate into the first ...

Embodiment 2

[0045] The manufacturing process of concrete composite self-insulation block, it comprises the following steps:

[0046] S1. Material preparation: Prepare materials according to the following materials and their weight ratios: cement: 25; fly ash: 15; waste residue: 40; water: 13;

[0047] S2. Mixing and stirring: put the above-mentioned waste slag into the batching bin according to the proportion, and send the mixed material into the mixer through the conveyor for stirring. After 4 minutes, add the cement, fly ash and water in the above proportion to carry out Stir fully, release the mixture after 8 minutes;

[0048] S3. Block forming: send the released mixture into the block forming machine through the conveyor, distribute the material in batches through the distributing machine, complete the block forming through the forming mold, and make a multi-hole block;

[0049] S4. One-time curing of blocks: Send the formed blocks together with the supporting plate into the first cu...

Embodiment 3

[0060] The manufacturing process of concrete composite self-insulation block, it comprises the following steps:

[0061] S1. Material preparation: Prepare materials according to the following materials and their weight ratios: cement: 20; fly ash: 20; waste residue: 30; water: 15;

[0062] S2. Mixing and mixing: put the above-mentioned waste slag into the batching bin according to the proportion, and send the mixed material into the mixer through the conveyor for mixing. After 3 minutes, add the cement, fly ash and water in the above proportion to carry out Stir fully, release the mixture after 7min;

[0063] S3. Block forming: send the released mixture into the block forming machine through the conveyor, distribute the material in batches through the distributing machine, complete the block forming through the forming mold, and make a multi-hole block;

[0064] S4. One-time curing of blocks: Send the formed blocks together with the supporting plate into the first curing kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com