Mechanism for driving double pumps

A driving mechanism and driving shaft technology, which is applied in the direction of machines/engines, pumps, pump devices, etc., can solve the problems of high cost, redundant structure, large volume, etc., and achieve the effects of low cost, compact structure, and convenient manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

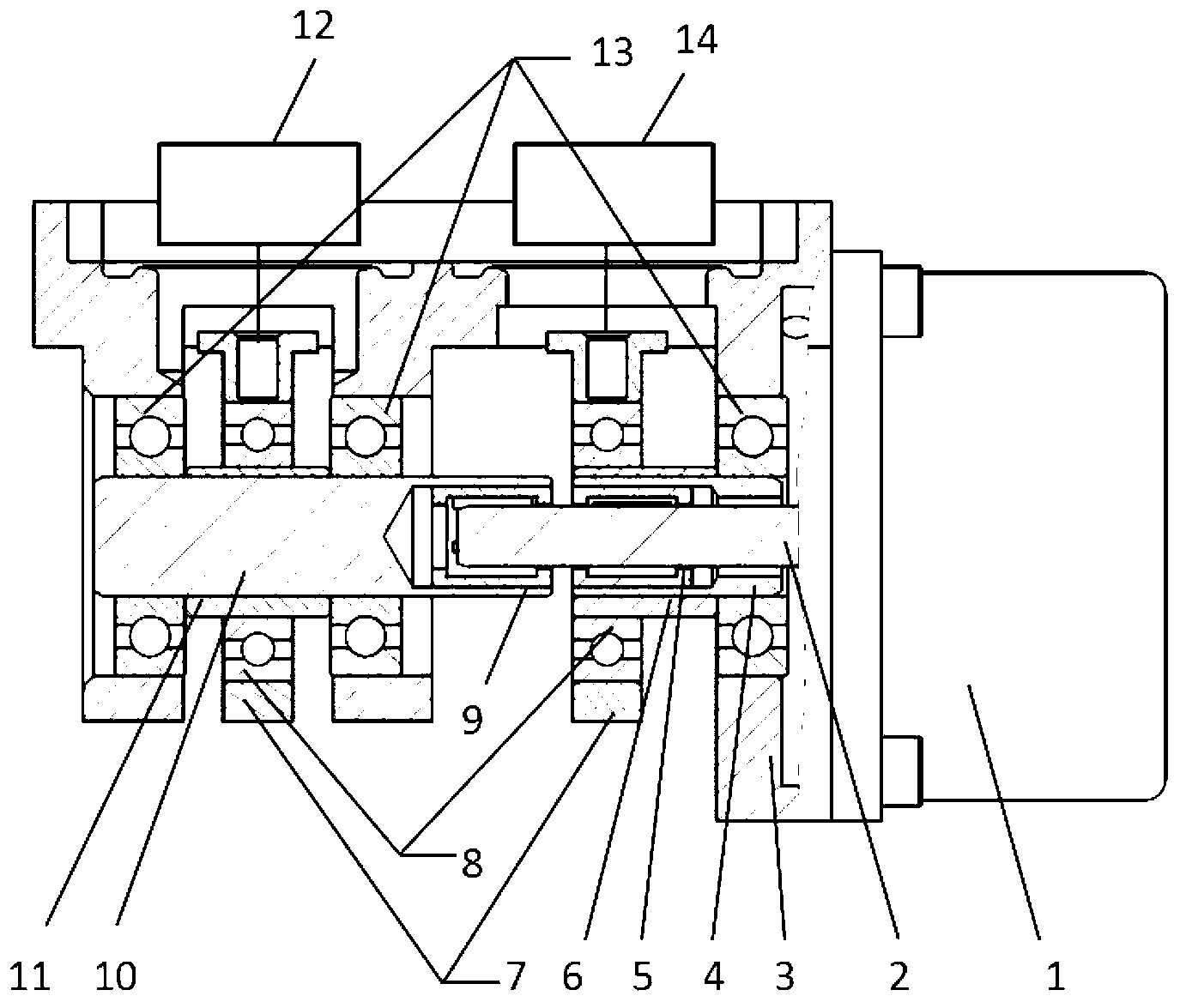

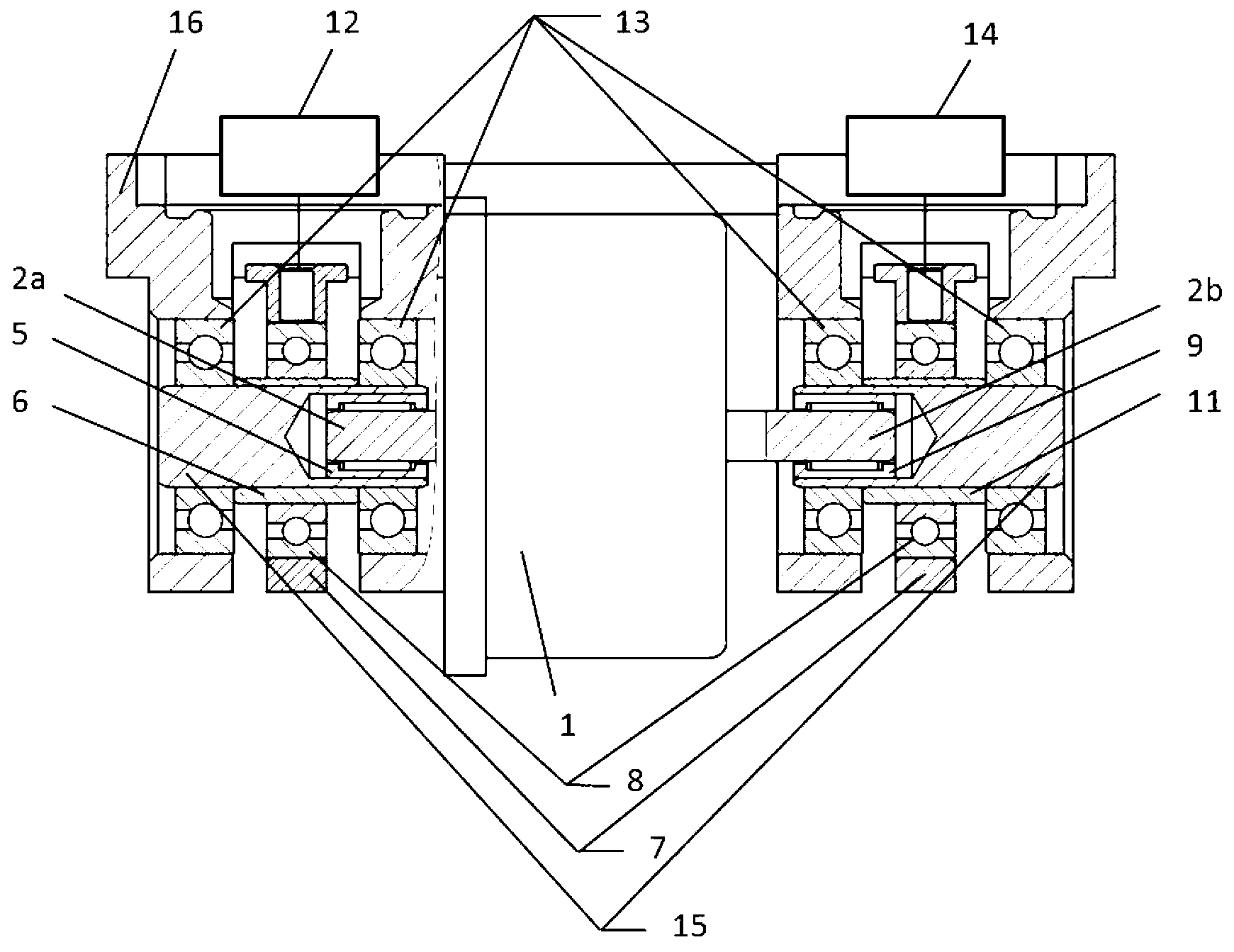

[0018] Such as figure 1 As shown, the present invention mainly consists of motor 1, motor shaft 2, bracket 3, drive shaft I4, drive shaft II10, one-way rotation device I5 and one-way rotation device II9, eccentric cam I6, eccentric cam II11, connecting rod 7, Cam bearing 8, support bearing 13 form the driving mechanism of a set of double pumps.

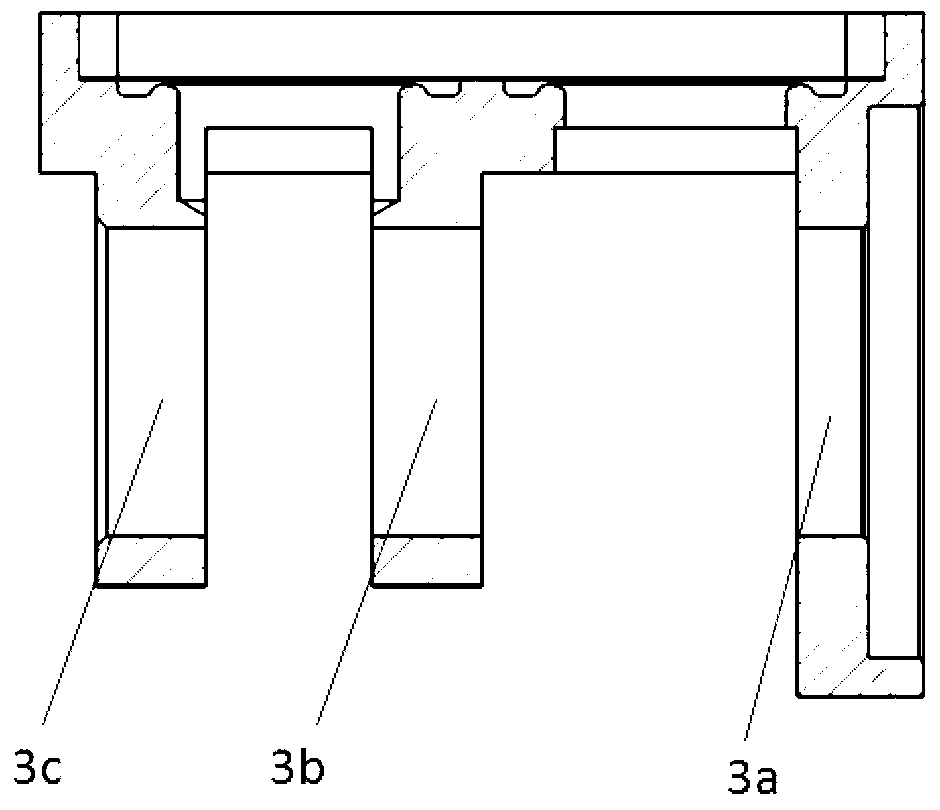

[0019] The motor 1 is installed on the bracket 3, the one-way rotating device I5 and the one-way rotating device II9, preferably the corresponding one-way bearing I and the one-way bearing II, are mounted on the drive shaft I4 and the drive shaft II10 in opposite directions, respectively. In the central hole on the side, the motor shaft 2 is coaxially connected with the one-way bearing I and the one-way bearing II. Pump II12 is a pressure supply pump, and pump I14 is a non-pressure supply pump, which is regarded as an emptying pump. This method can be realized by three support bearings 13 respectively installed in the bearing races 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com