Local resonance type photonic crystal vibration damping gear

A phononic crystal, local resonance technology, used in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of incomplete elimination, noise reduction, vibration weakening, etc., and achieve good vibration reduction. Noise reduction effect, reduce vibration noise, use reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

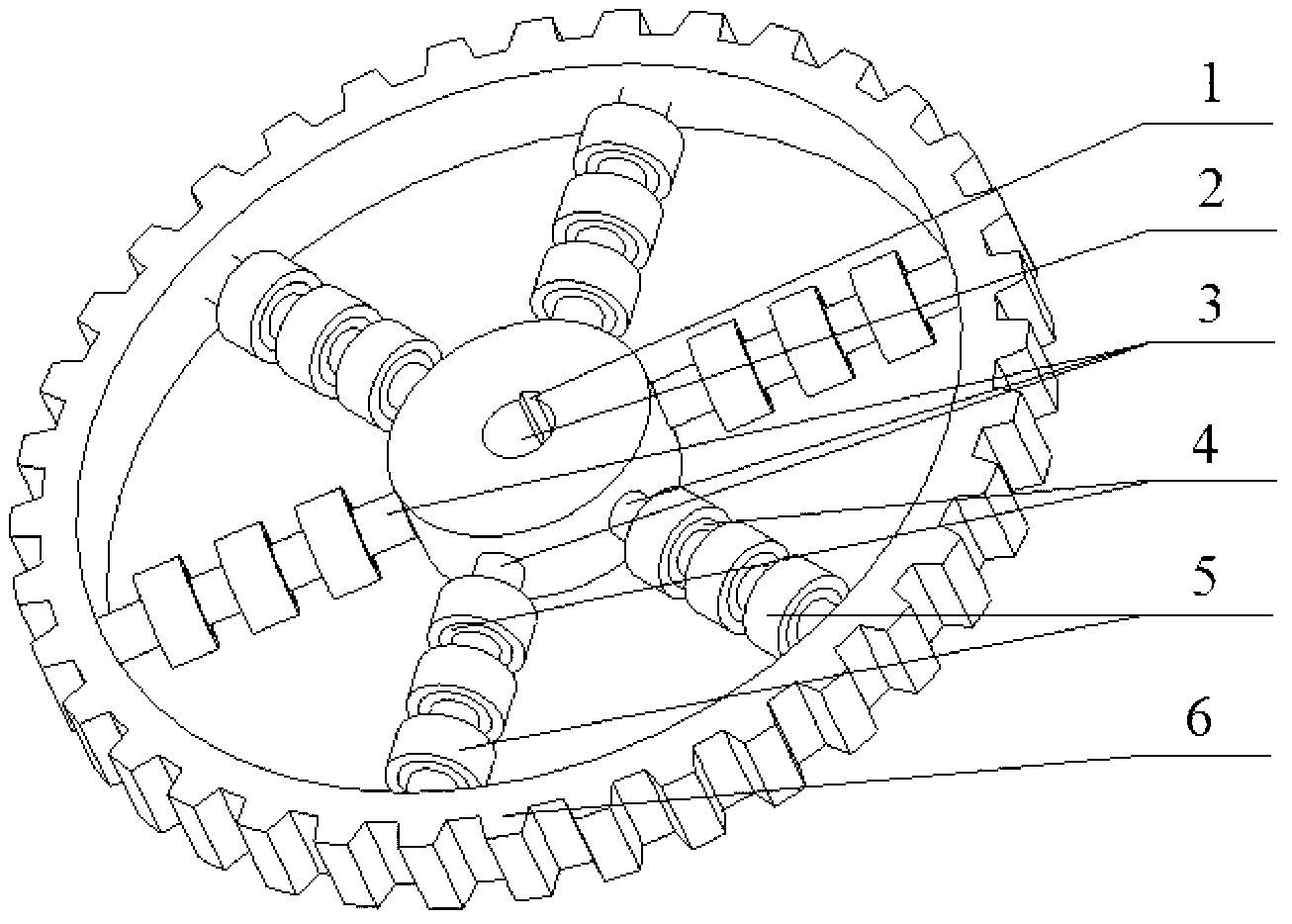

[0012] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

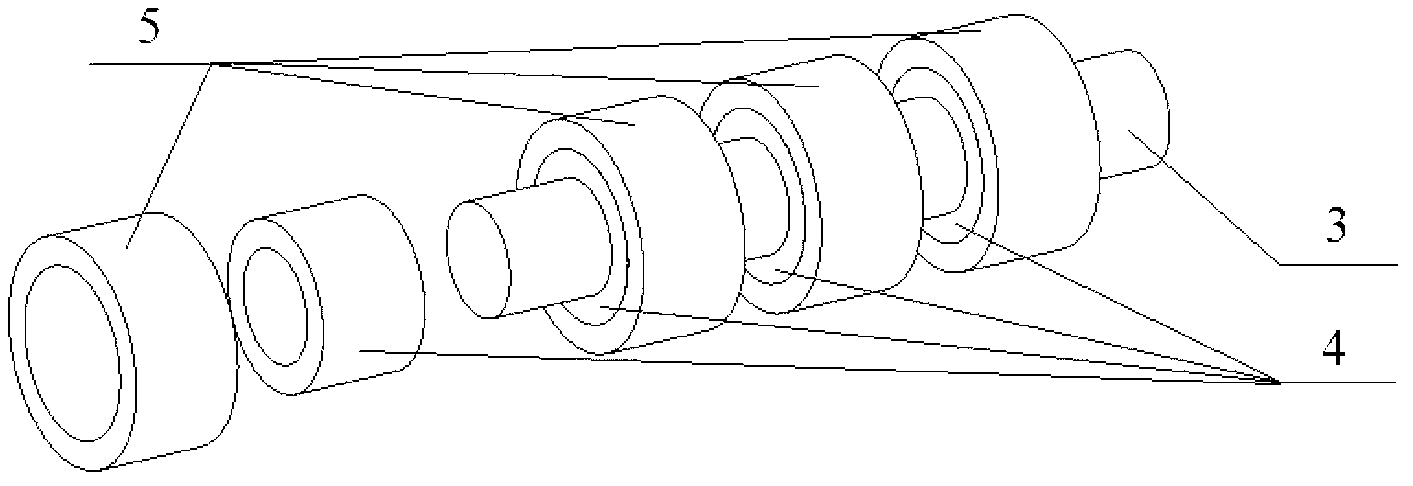

[0013] Combine Figure 1~2 , The present invention is mainly aimed at gear damping in the middle and low frequency range. Here, the band gap characteristics of the local resonance type phononic crystal in the middle and low frequency range are used to realize the vibration and noise reduction effect of the gear in the middle and low frequency range. The principle is to use a local resonance type phononic crystal rod to replace the gear spokes, and change the circumferential shear wave received by the gear into a bending wave of the phononic crystal rod. When being excited by the meshing frequency located in the band gap of the phononic crystal rod, each local oscillator resonates and interacts with the elastic wavelength traveling wave, thereby inhibiting its propagation and achieving the purpose of vibration and noise reduction. The rod-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com