Shield ball fitting for converter station valve hall

A shielding ball and converter station technology, applied in the field of shielding ball fittings, can solve problems such as complex structure of shielding ring fittings, difficulties in production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

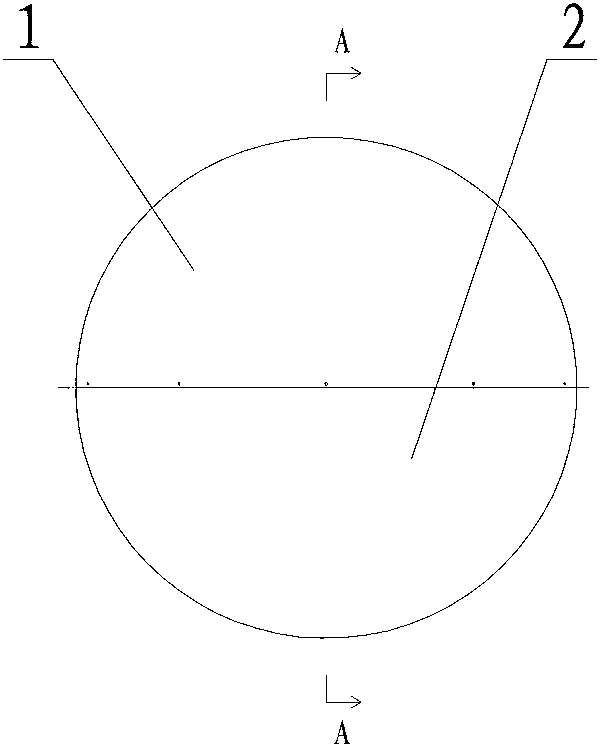

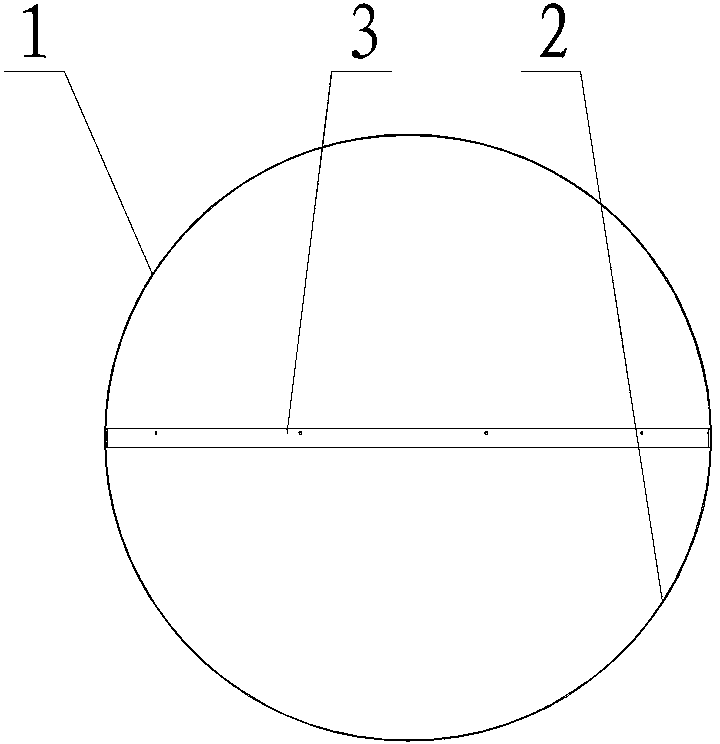

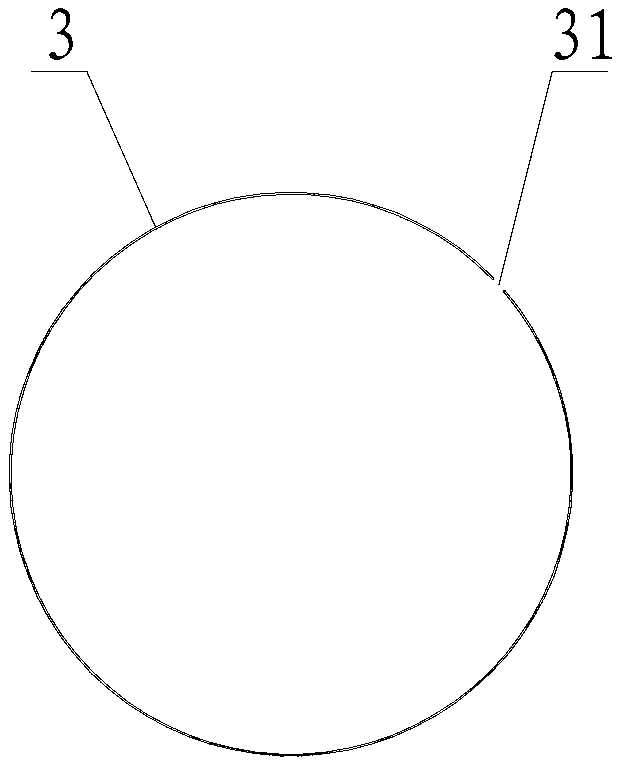

[0015] Embodiment of the shielding ball fittings for the valve hall of the converter station of the present invention: as Figure 1-5 As shown, including the spherical shell and the intermediate ring body 3, the spherical shell is formed by butt jointing of the upper shielding hemisphere 1 and the lower shielding hemisphere 2, and the upper shielding hemisphere 1 and the lower shielding hemisphere 2 are formed by spinning a 2mm thick aluminum alloy plate; The middle ring body 3 is set at the butt joint position of the inner spherical surface of the spherical shell, and is surrounded by a 4mm thick aluminum alloy plate. The lower shielding hemisphere 2 and the middle ring body 3 are connected together by spot welding, while the upper shielding hemisphere The hemisphere 1 and the middle ring body 3 are detachably connected by countersunk head screws arranged along the circumference of the middle ring body connected between the two, so that after the upper shielding hemisphere 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com