Catalyst for preparing crotonyl alcohol by selective hydrogenation of crotonaldehyde and preparation method of catalyst

A selective, catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of easy deactivation and poor stability of Ir-based catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

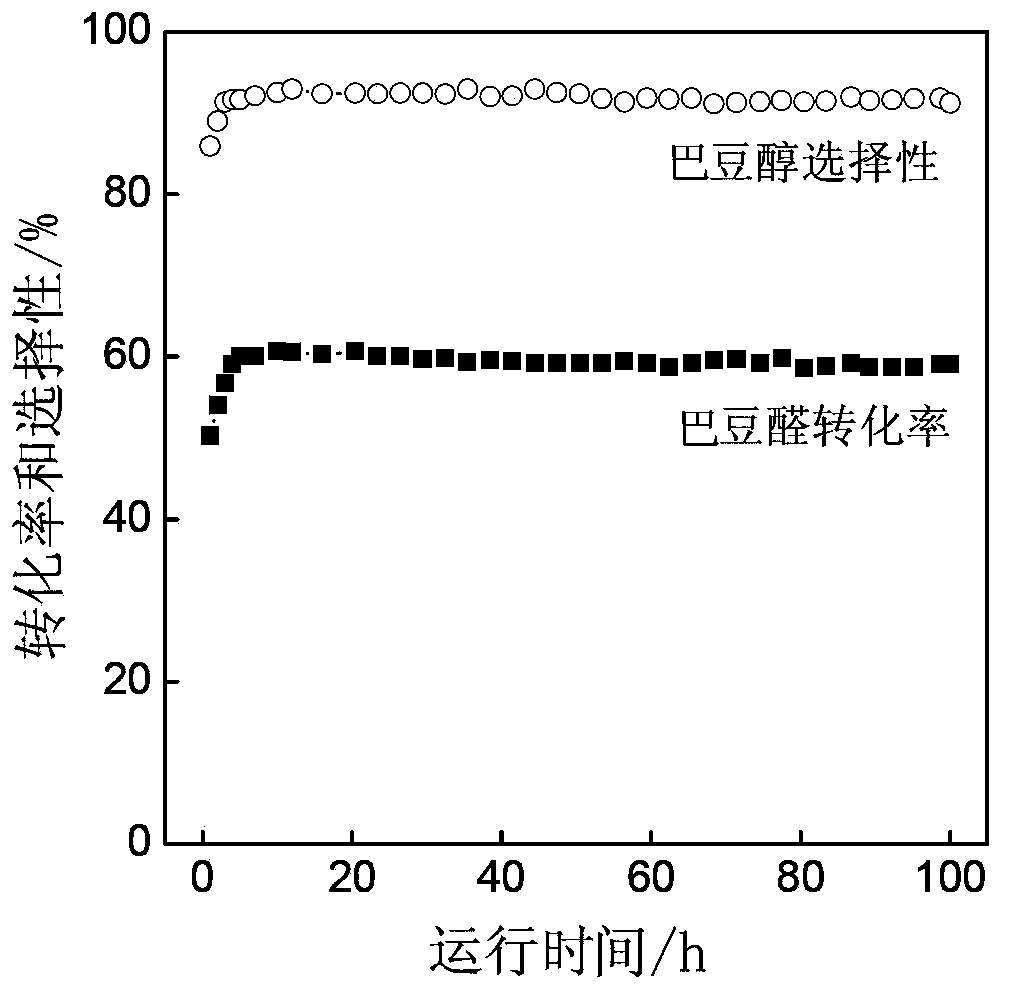

Image

Examples

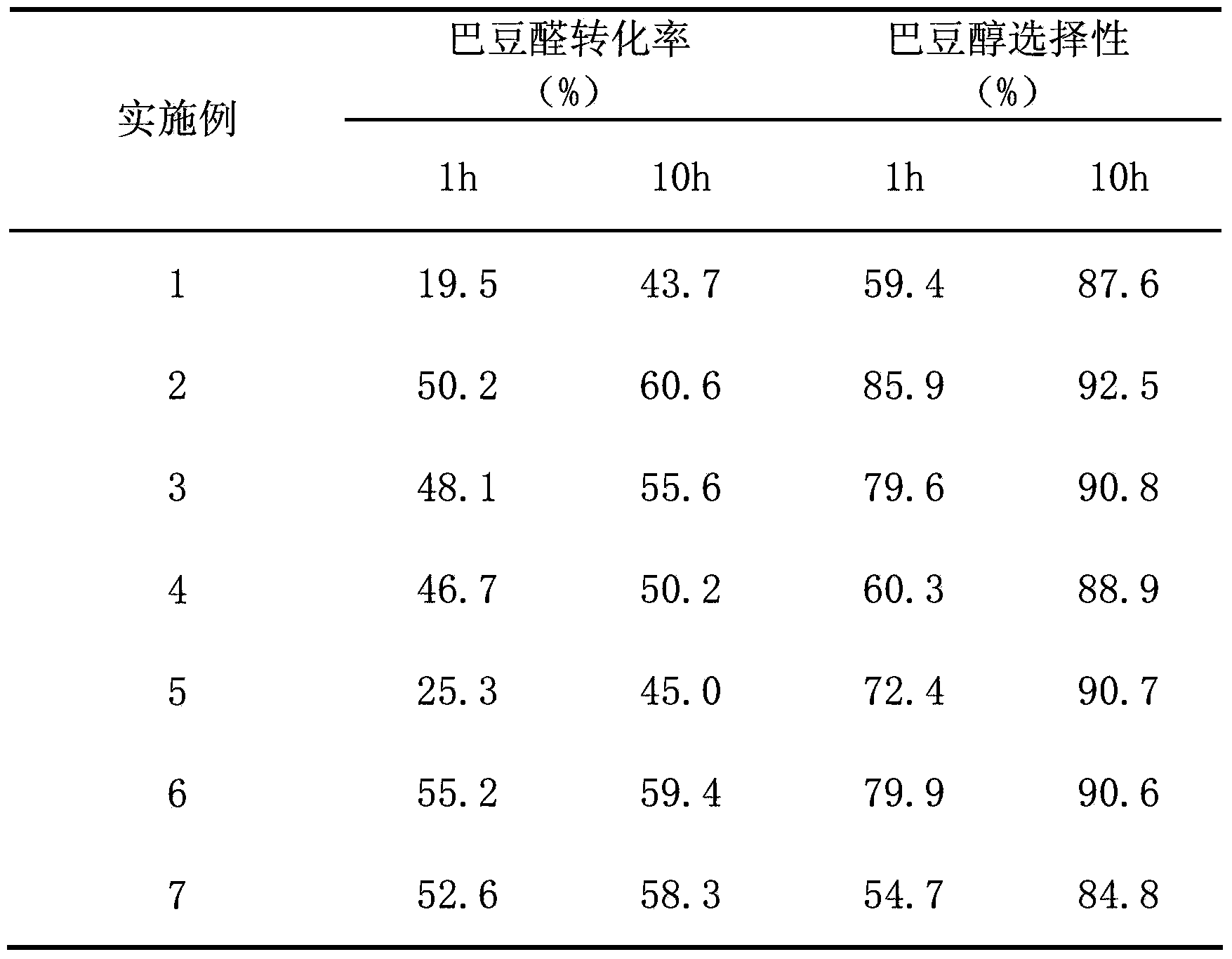

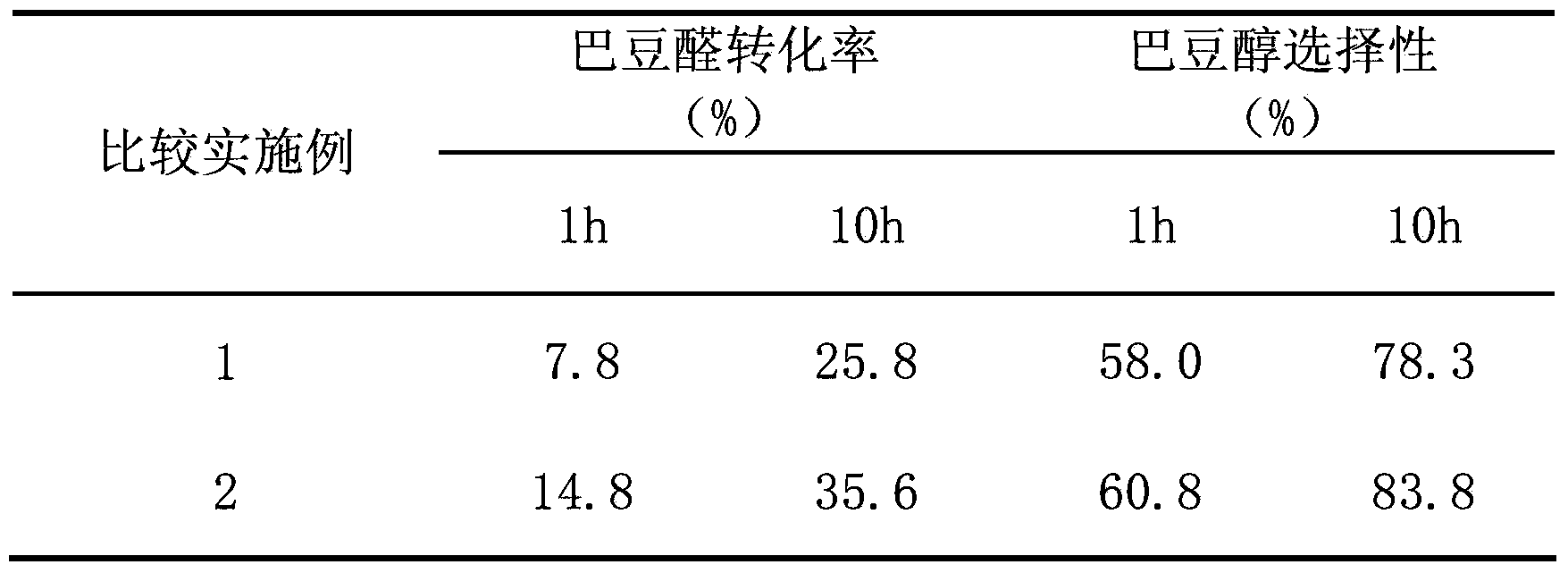

Embodiment 1

[0018] ① SiO according to the total mass percentage of Fe-Cr 2 0.2% of Fe / Cr, the mass ratio of Fe / Cr is 1:1, weigh a certain amount of Fe(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 O, add an appropriate amount of water to dissolve and mix well, and the corresponding amount of SiO 2 Add the powder into the mixed solution, stir evenly, and soak at room temperature for 12 hours;

[0019] ② Afterwards, evaporate the liquid in a water bath at 90°C, and bake it in an air atmosphere at 500°C for 4 hours to obtain Fe-Cr / SiO 2 carrier.

[0020] ③ According to the mass percentage of Ir, it is Fe-Cr / SiO 2 3% of the carrier, the mass percentage of Fe is Fe-Cr / SiO 2 0.3% of the carrier, absorb a certain amount of Ir(acac) 3 and Fe(acac) 3 Benzene solution, and mix well, the corresponding amount of Fe-Cr / SiO 2 The carrier is added to the mixed solution, stirred evenly, and soaked at room temperature for 3 hours;

[0021] ④ After that, evaporate the liquid to dryness in a water bath ...

Embodiment 2

[0025] ① SiO according to the mass percentage of Fe-Cr 2 0.7% of Fe / Cr, the mass ratio of Fe / Cr is 1:1, weigh a certain amount of Fe(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 O, add an appropriate amount of water to dissolve and mix well, and the corresponding amount of SiO 2 Add the powder into the mixed solution, stir evenly, and soak at room temperature for 12 hours;

[0026] ② Afterwards, evaporate the liquid in a water bath at 90°C, and bake it in an air atmosphere at 500°C for 4 hours to obtain Fe-Cr / SiO 2 carrier.

[0027] ③ According to the mass percentage of Ir, it is Fe-Cr / SiO 2 3% of the carrier, the mass percentage of Fe is Fe-Cr / SiO 2 0.3% of the carrier, absorb a certain amount of Ir(acac) 3 and Fe(acac) 3 Benzene solution, and mix well, the corresponding amount of Fe-Cr / SiO 2 The carrier is added to the mixed solution, stirred evenly, and soaked at room temperature for 3 hours;

[0028] ④ After that, evaporate the liquid to dryness in a water bath at 90°C,...

Embodiment 3

[0032] ① SiO according to the mass percentage of Fe-Cr 2 1.0% of Fe / Cr, the mass ratio of Fe / Cr is 1:1, weigh a certain amount of Fe(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 O, add an appropriate amount of water to dissolve and mix well, and the corresponding amount of SiO 2 Add the powder into the mixed solution, stir evenly, and soak at room temperature for 12 hours;

[0033] ② Afterwards, evaporate the liquid in a water bath at 90°C, and bake it in an air atmosphere at 500°C for 4 hours to obtain Fe-Cr / SiO 2 carrier.

[0034] ③ According to the mass percentage of Ir, it is Fe-Cr / SiO 2 3% of the carrier, the mass percentage of Fe is Fe-Cr / SiO 2 0.3% of the carrier, absorb a certain amount of Ir(acac) 3 and Fe(acac) 3 Benzene solution, and mix well, the corresponding amount of Fe-Cr / SiO 2 The carrier is added to the mixed solution, stirred evenly, and soaked at room temperature for 3 hours;

[0035] ④ After that, evaporate the liquid to dryness in a water bath at 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com