Automatic control system of road crusher

An automatic control system and stone crusher technology, applied in grain processing, etc., can solve problems such as low production efficiency and waste of energy, and achieve the effects of low cost, stable and reliable system, and flexible control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

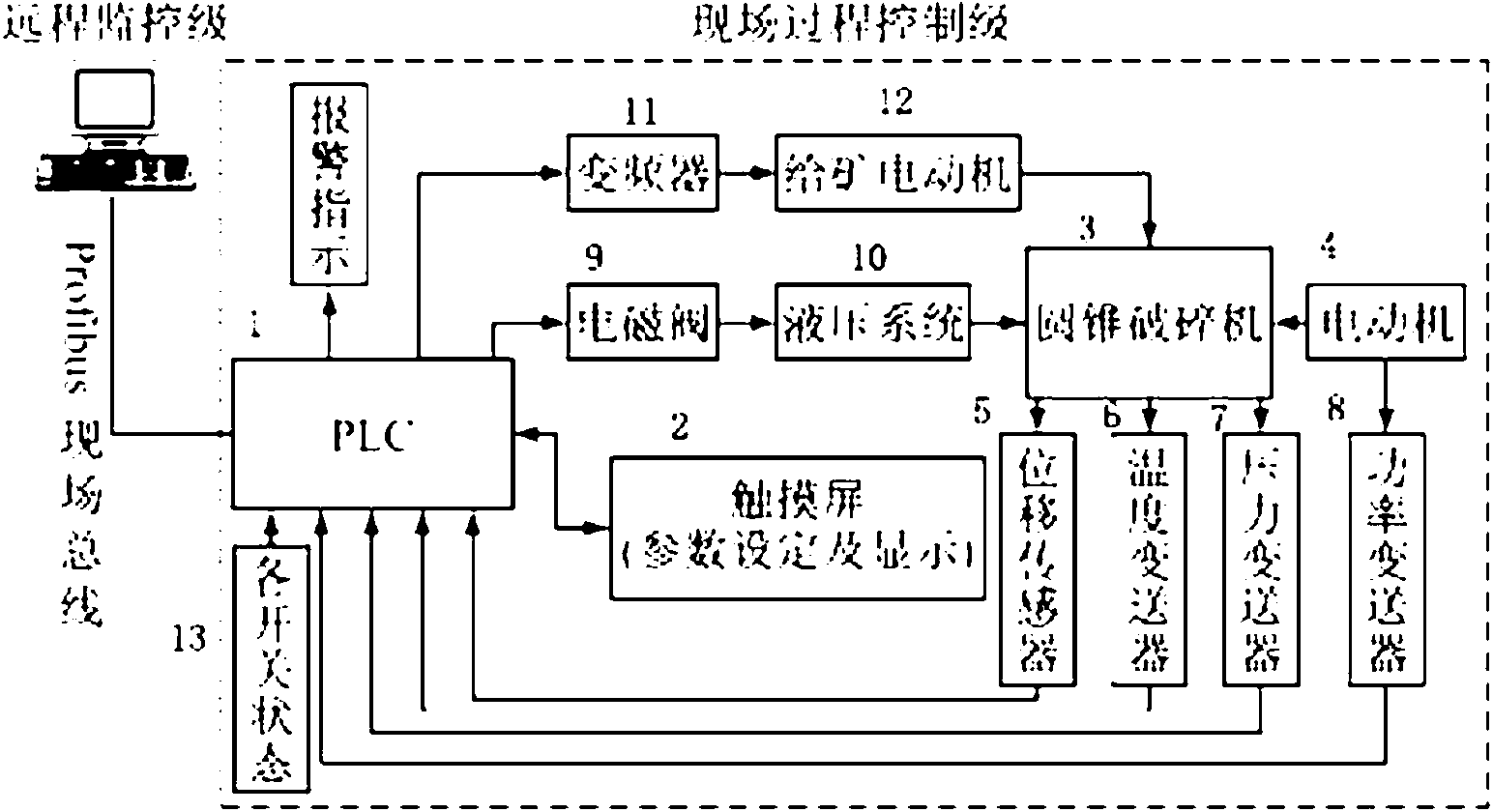

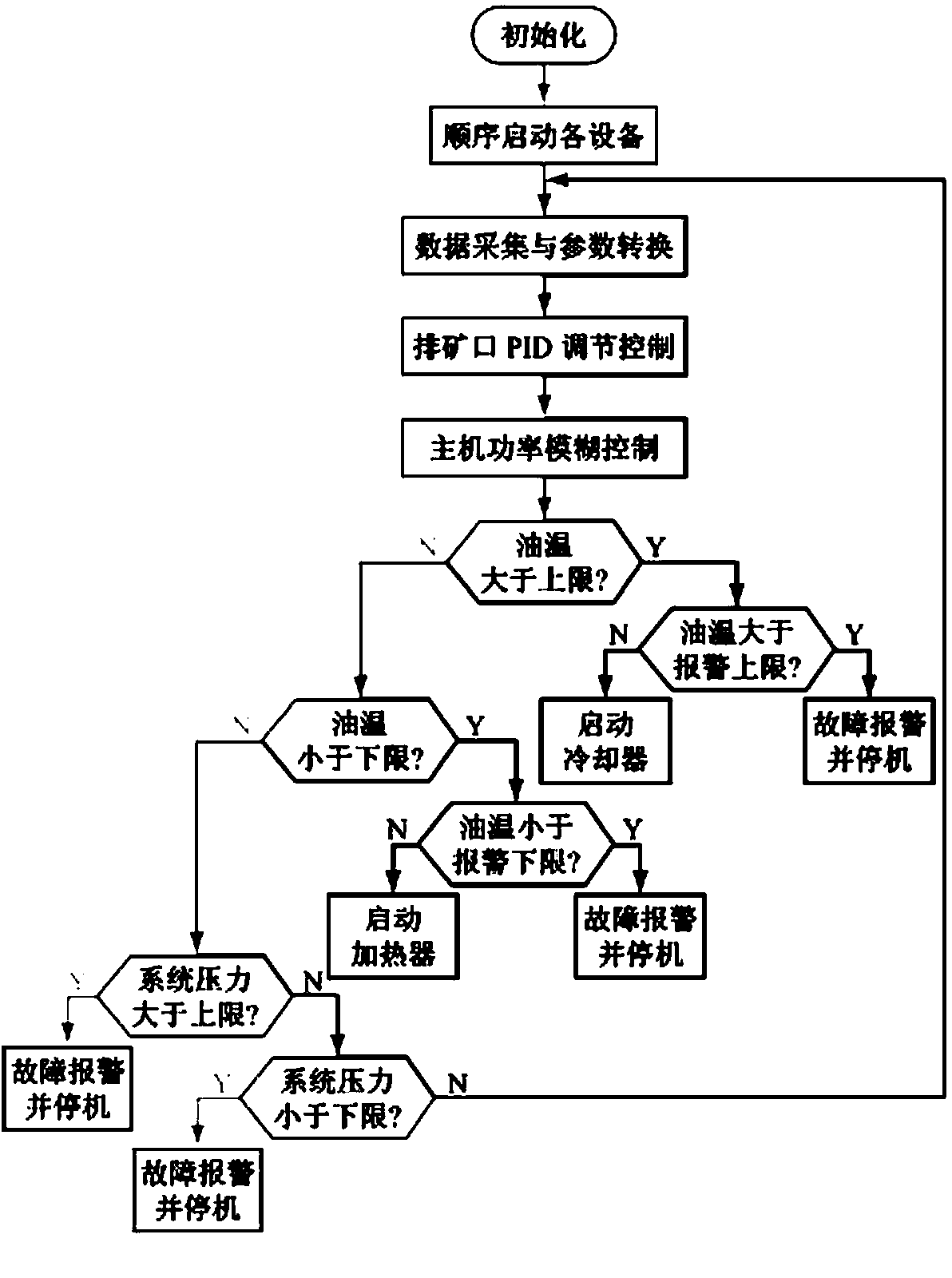

[0031] Please refer to figure 1 As shown, it has shown the specific structure of the preferred embodiment of the present invention, the automatic control system of this road rock breaker 3 includes the field process control level and the remote monitoring level, wherein, the remote monitoring level is composed of computer and connected to the computer Composed of a display and a keyboard, the remote monitoring level realizes data communication with the on-site process control level through the field bus, so that the remote monitoring level can view various states of the construction site and achieve real-time remote monitoring effects.

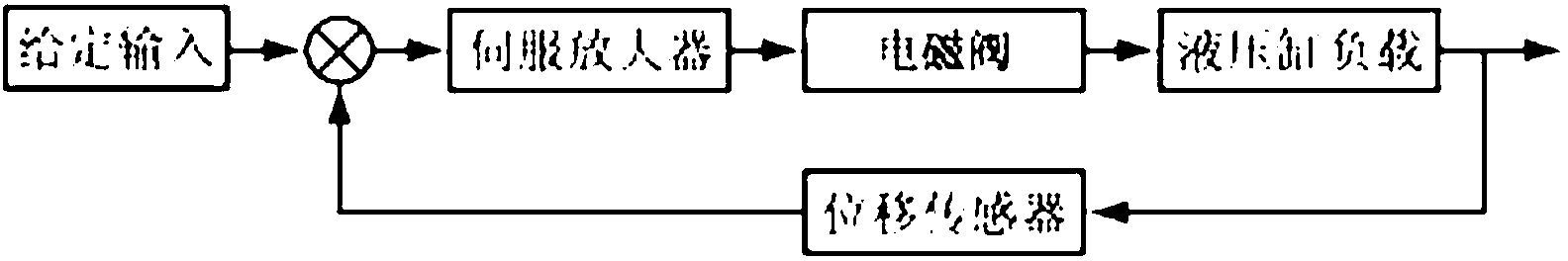

[0032] The on-site process control level includes PLC 1, touch screen 2 connected to PLC 1, rock crusher 3, motor 4 connected to rock crusher 3, displacement sensor 5, temperature transmitter 6, pressure transmitter 7 and motor 4 connected The power transmitter 8, the solenoid valve 9 and the hydraulic system 10 are connected between the PLC 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com