Apparatus and method for monitoring resistance welding and system thereof

A resistance welding and resistance technology, applied in welding monitoring devices, resistance welding equipment, welding power sources, etc., can solve problems such as difficulty in accurately grasping welding inferiority, inability to use ultrasonic inspection equipment, etc., to reduce test time, improve reliability, and the effect of tuning reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Matters defined in the description, such as detailed construction and elements, are nothing but specific details provided to assist those of ordinary skill in the art in a comprehensive understanding of the invention, and thus the present invention is not limited thereto.

[0029] In order to clearly explain the present invention, descriptions of parts irrelevant to the explanation will be omitted. Throughout the description of the present invention, the same drawing reference numerals are used for the same elements in the various figures.

[0030] Throughout the specification and claims, the terms "comprising" and / or "comprising" mean one or more other components, steps, operations and / or in addition to the described components, steps, operations and / or elements, Existing or added components that are not excluded.

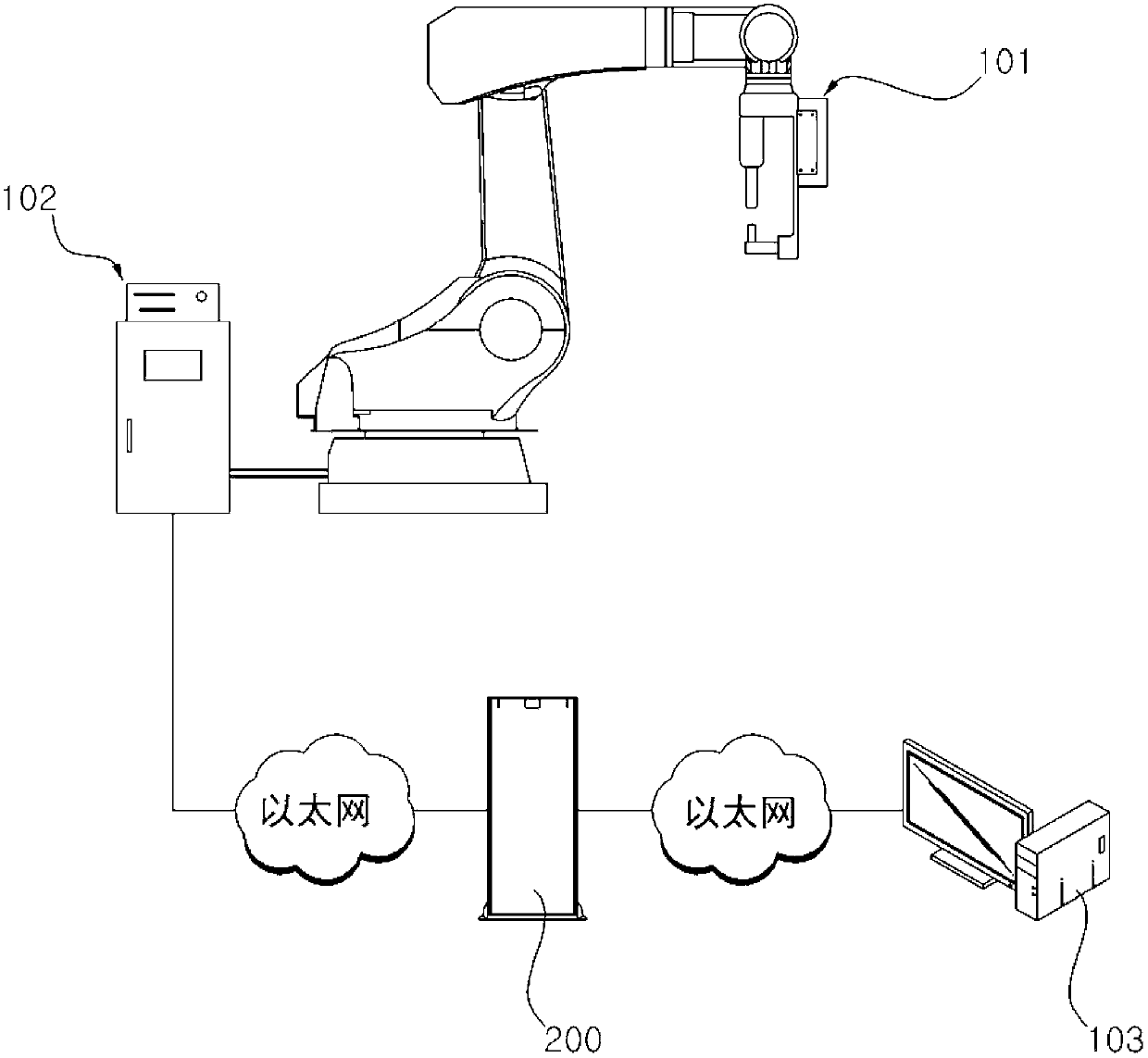

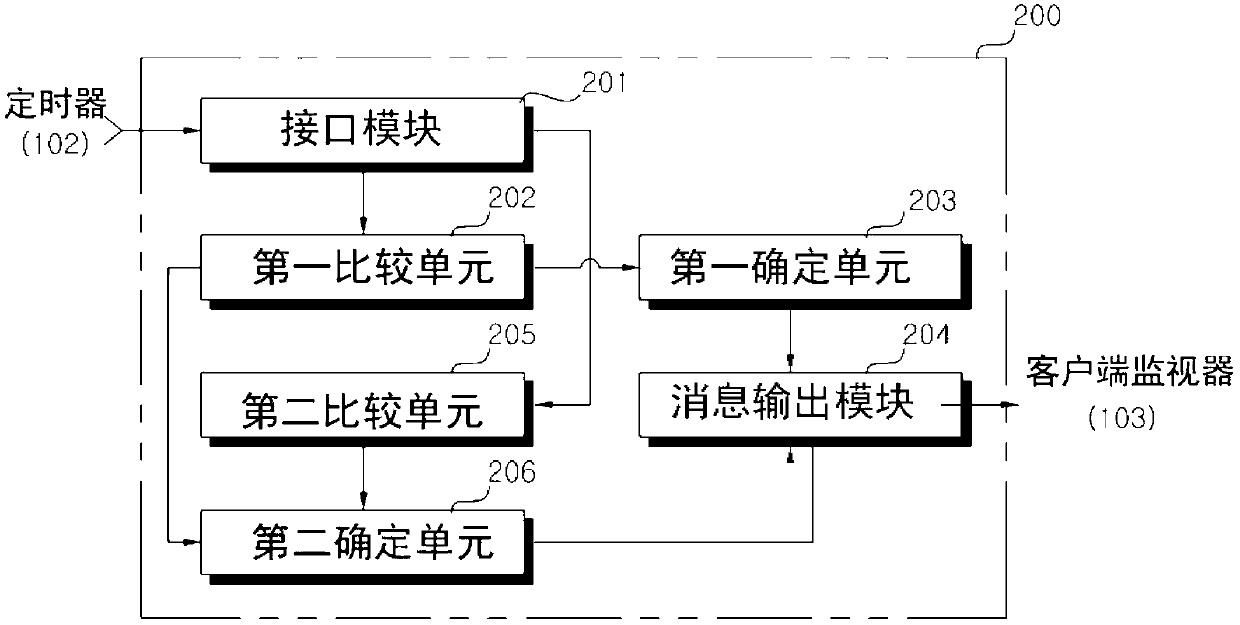

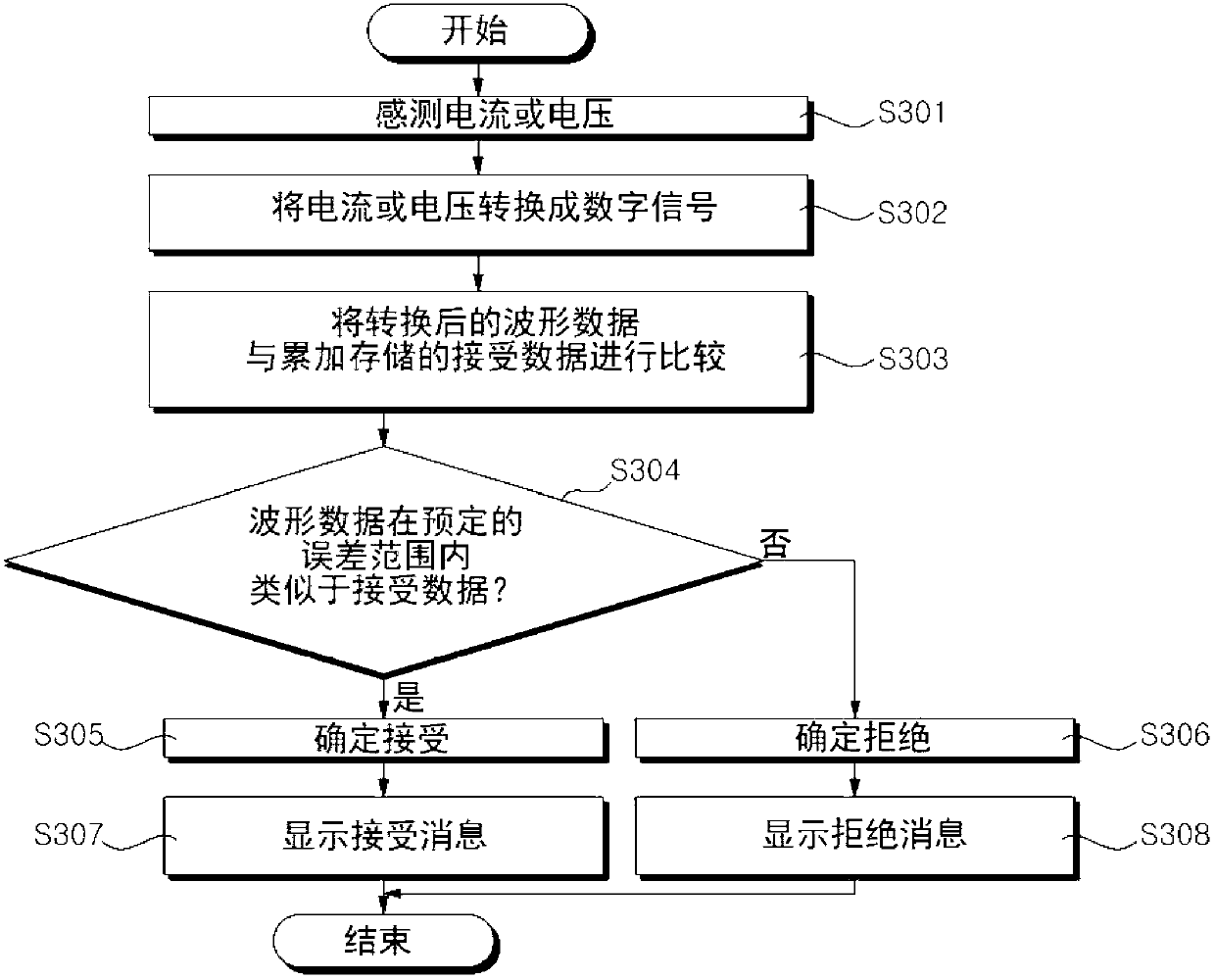

[0031] figure 1 is a diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com