Electronic Label Cigarette Packing Box

A technology of electronic labels and packaging boxes, which is applied in packaging, transportation, packaging, boxes, etc., can solve the problems of production line failure, blind spots of photoelectric sensors, labor and time-consuming, etc., to maintain ecological construction, improve the effect of repeated use, and improve The effect of cost reduction and efficiency increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail:

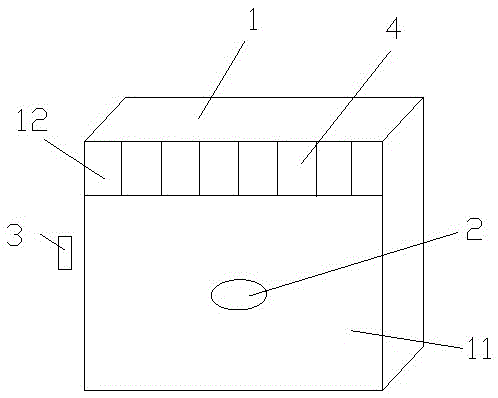

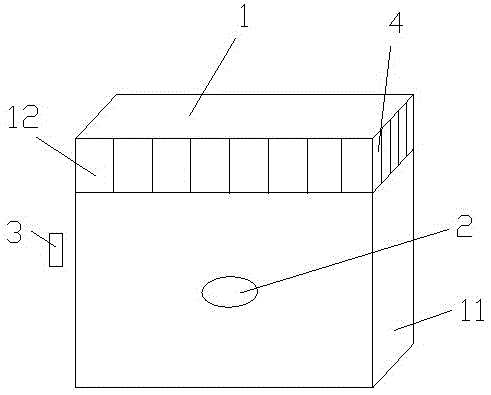

[0018] Such as figure 1 As shown, an electronic label cigarette packaging box of the present invention includes a box body 1 and an electronic label 2 placed on the box body, wherein the box body 1 is a hexahedron, and one of the six sides is composed of an opaque polymer matrix 11 and a transparent Composed of a polymer matrix 12, the opaque polymer matrix 11 and the transparent polymer matrix 12 are produced from polymer materials, and the two are compatible to form a whole surface, wherein the opaque polymer matrix 11 is located in the middle of the surface, corresponding to the position of the photoelectric sensor 3 . Through the transparent molecular matrix 12 , the contents 4 of the box body 1 can be recognized with naked eyes.

[0019] In order to facilitate automatic production, the four sides of the box are composed of opaque polymer substrates 11 and transparent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com