Optical fiber drawing method for large-diameter optical fiber preform rod

An optical fiber preform, large-diameter technology, applied in glass fiber drawing devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of fiber strength drop, air leakage, drawing furnace oxidation, etc., and achieve the effect of not easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

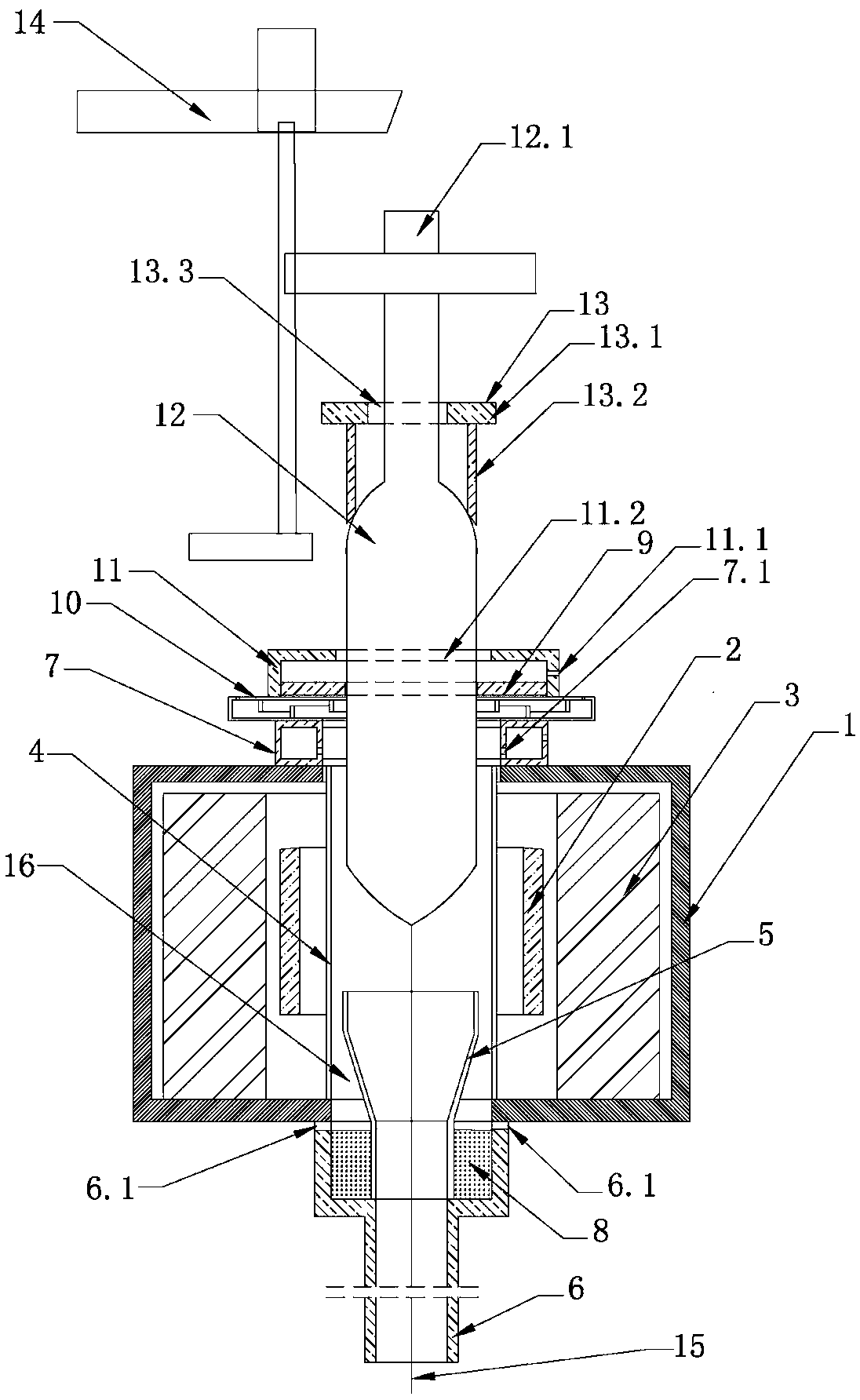

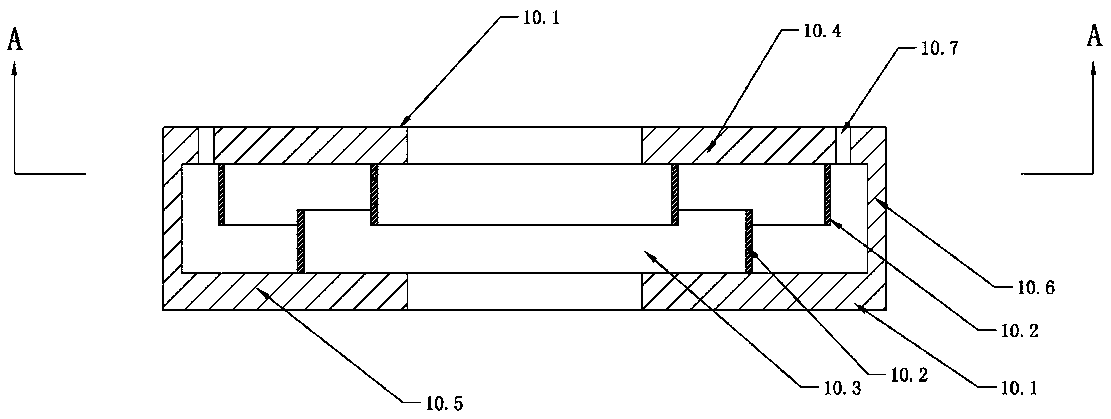

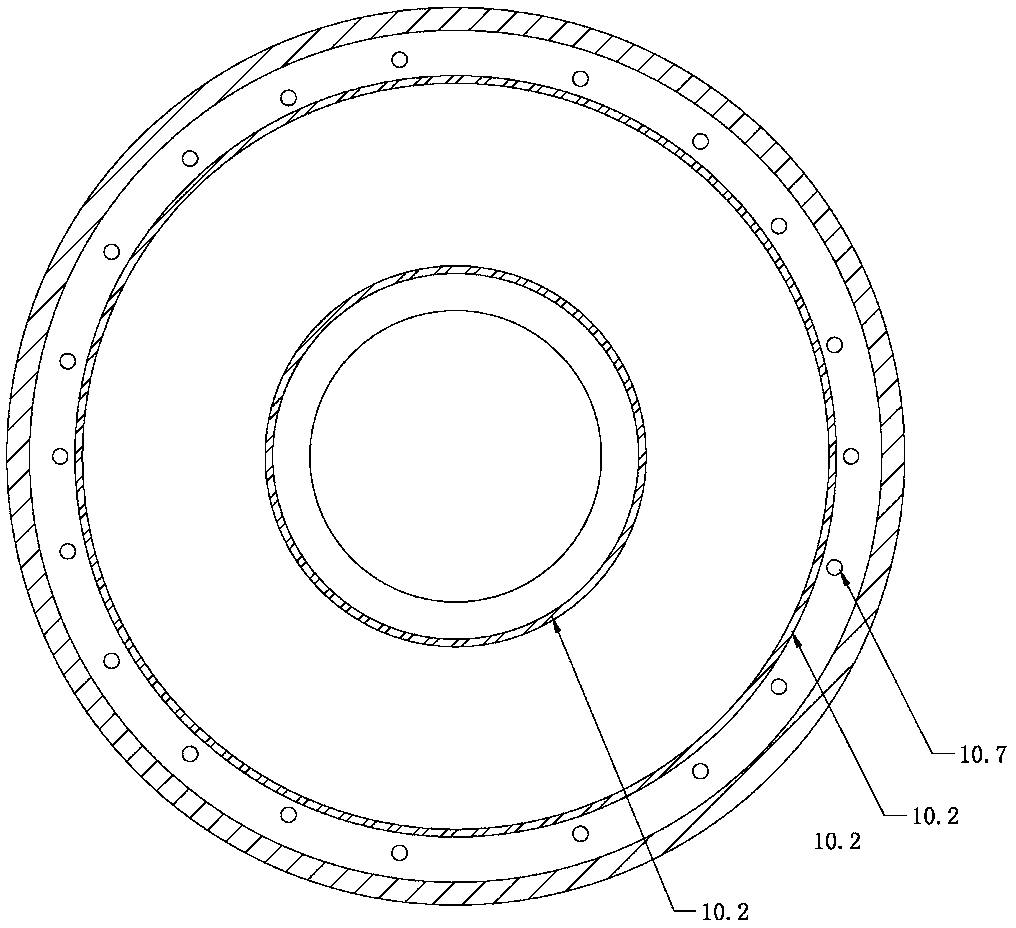

[0013] Such as figure 1 , figure 2 and image 3 As shown, the optical fiber drawing furnace includes a furnace body 1, a heating element 2, an insulating body 3, a middle casing 4, a guide tube 5, an extension tube 6, a furnace top gas plate 7, a spacer ring 8, an elastic graphite ring piece 9, a guide tube Air disk 10 and air seal cover 11; air guide disk 10 includes a hollow ring disk 10.1 and several ring pieces 10.2, the inner ring of the hollow ring disk 10.1 is an open opening 10.3, and several ring pieces 10.2 are on the upper inner wall 10.4 of the hollow ring disk , lower inner wall 10.5 upper and lower adjacent staggered installation, on the upper inner wall 10.4 near the outer wall 10.6 of the hollow ring disk 10.1 is provided with a circle of some air outlet holes 10.7; 10.7 Vertically upward, the elastic graphite ring piece 9 is installed on the hollow ring disk 10.1 inside the air outlet 10.7; the spacer ring 8 is arranged between the flow guide tube 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com