Working method of buffer suitable for adjusting stress buffering automatically

A working method and automatic adjustment technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of slider rebound and other problems, achieve the effect of alleviating the pressure in the cavity and prolonging the life of the buffer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

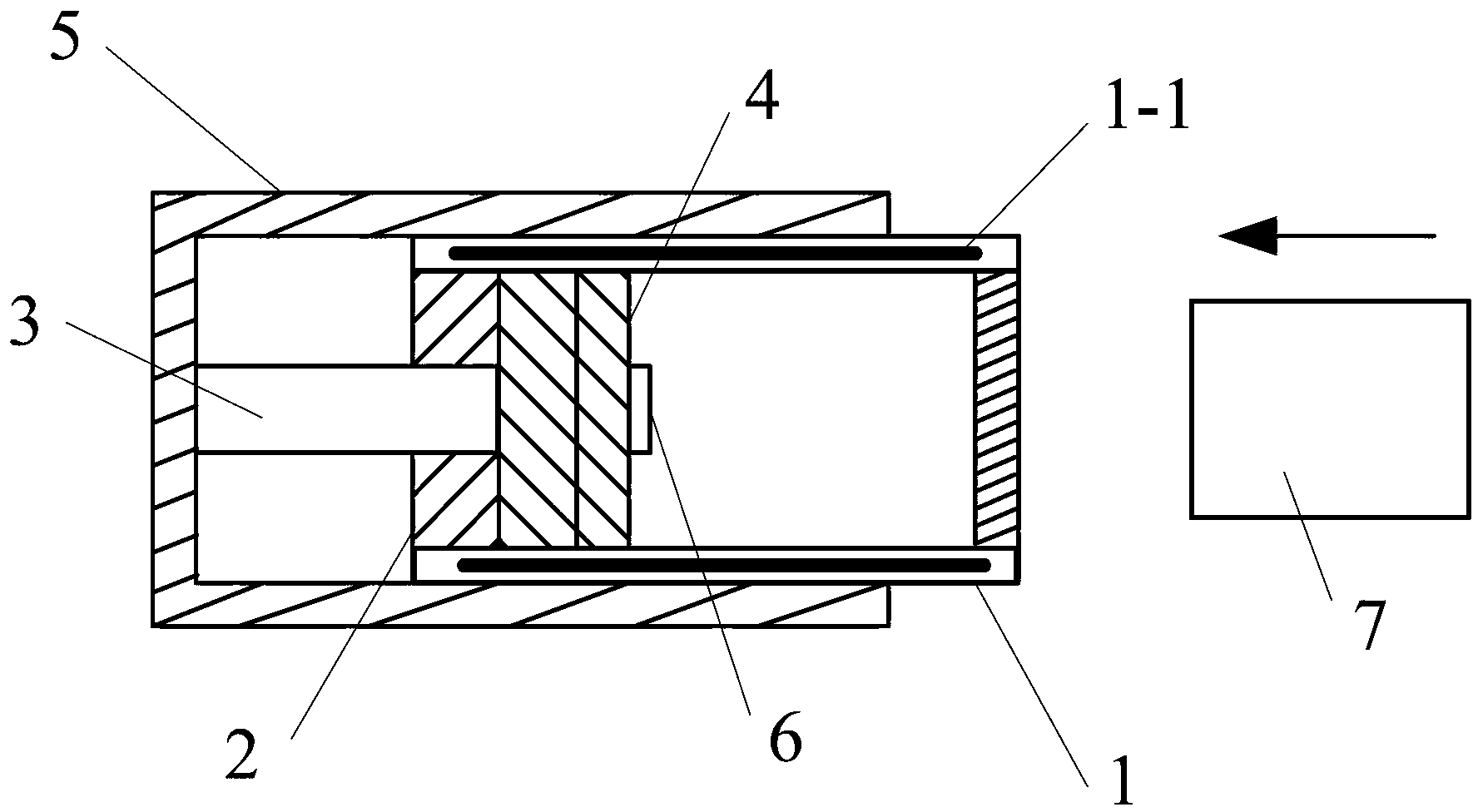

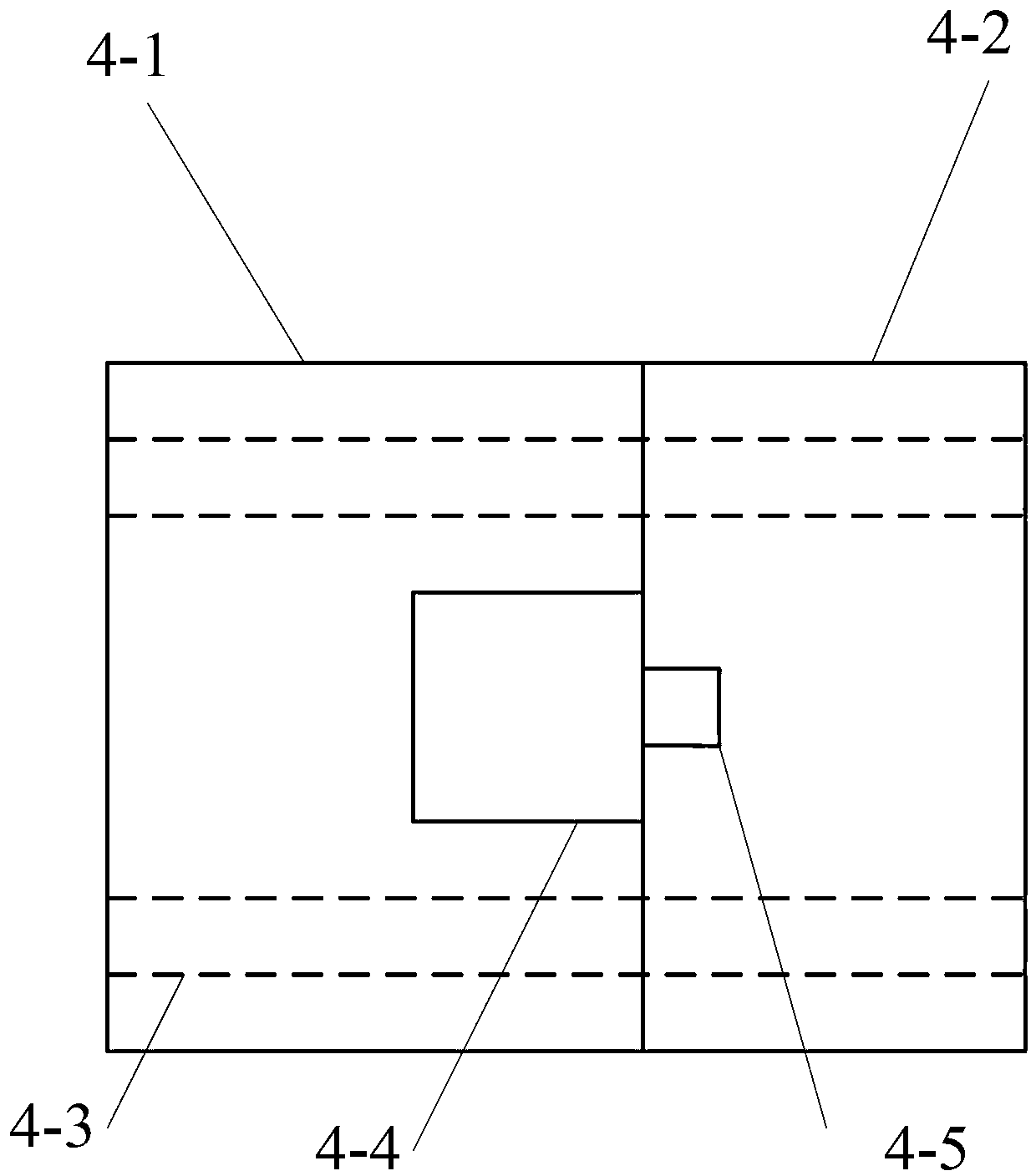

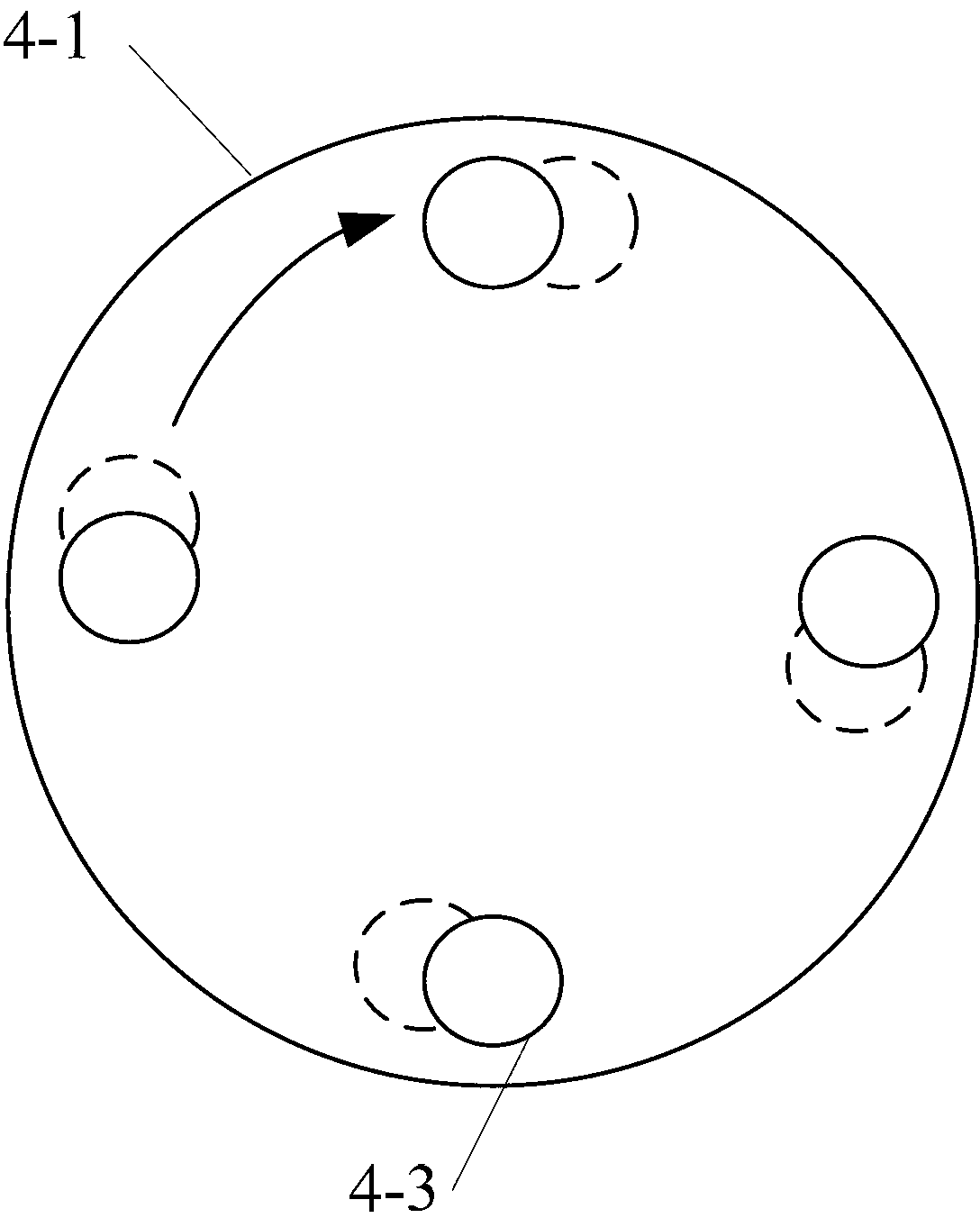

[0017] See figure 1 and Figure 4 , a working method suitable for automatically adjusting a buffer under force, the buffer includes: a cylinder 1 that is cylindrical and filled with a buffer medium, and a cylinder head is provided at the open end of the cylinder 1 2, and close the opening, the central axis of the cylinder head 2 is provided with an axially extending central through hole; a piston rod 3 passes through the central through hole, and is sealed and fitted; the top of the piston rod 3 is provided with a piston Body assembly 4, the piston body assembly is suitable for piston movement in the cylinder 1; when buffering, the right end surface of the cylinder 1 is used as a contact surface that collides with the slider 7, and the slider 7 is Magnetic slider; the side wall of the cylinder body 1 is wound with an electromagnetic coil 1-1, and the right end surface of the piston body assembly 4 is provided with a pressure sensor 6 for detecting medium pressure, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com