Calibration method of fiber grating water-soil interface sensor probe

A technology of sensing probes and optical fiber gratings, applied in the field of calibration devices for optical fiber grating water-soil interface sensing probes, can solve the problems of resistance strain gauge errors, inability to simulate sensing probes, etc., and achieve reliable data reference, easy-to-obtain materials, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

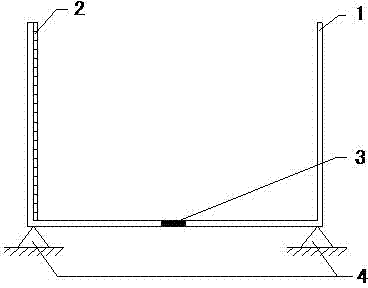

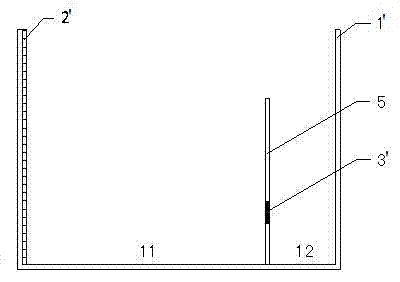

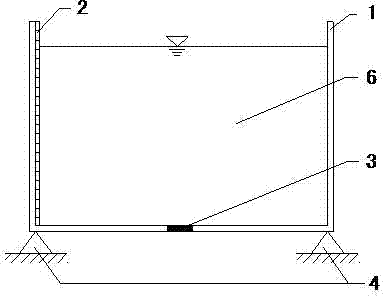

[0062] Fig. 1 is a schematic structural diagram of the water pressure calibration device according to the present invention; Fig. 2 is a structural schematic diagram of the water and soil pressure calibration device according to the present invention.

[0063] Such as figure 1 and figure 2 Shown: a fiber grating water-soil interface sensor probe calibration device, including water pressure calibration device and water-soil pressure calibration device, wherein,

[0064] The water pressure calibration device includes a first transparent water tank 1, a first scale 2, a first sensing probe 3 and a support 4. The first transparent water tank 2 has a U-shaped structure, and a first hole, the first scale 2 is vertically arranged on the inner wall of one side of the first transparent water tank 1, and the first sensing probe 3 is embedded in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com