A Porous Metal Composite Structure Array Electret Noise Detector

A technology of porous metal and composite structure, applied in electret electrostatic transducers, instruments, measuring devices, etc., can solve problems such as difficult to measure accurately, loss, and inability to accurately judge the direction of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

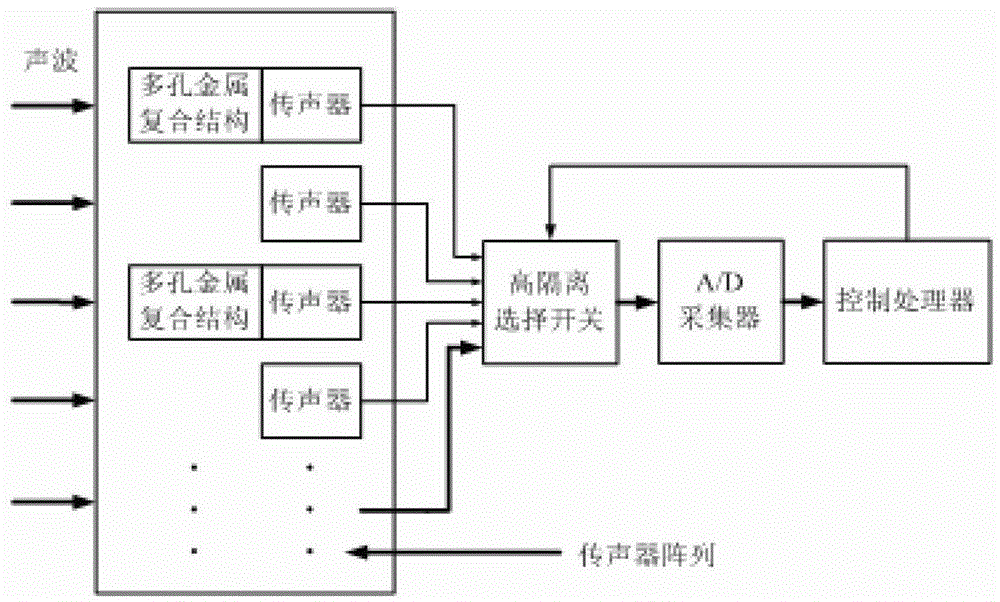

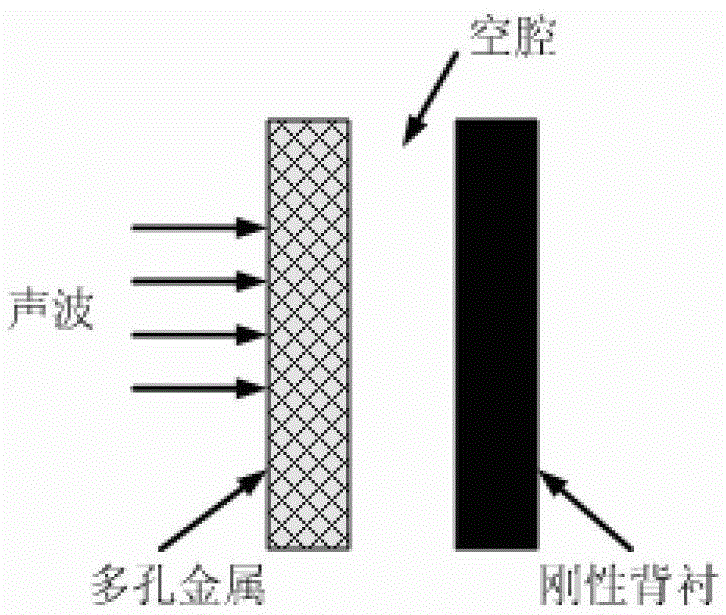

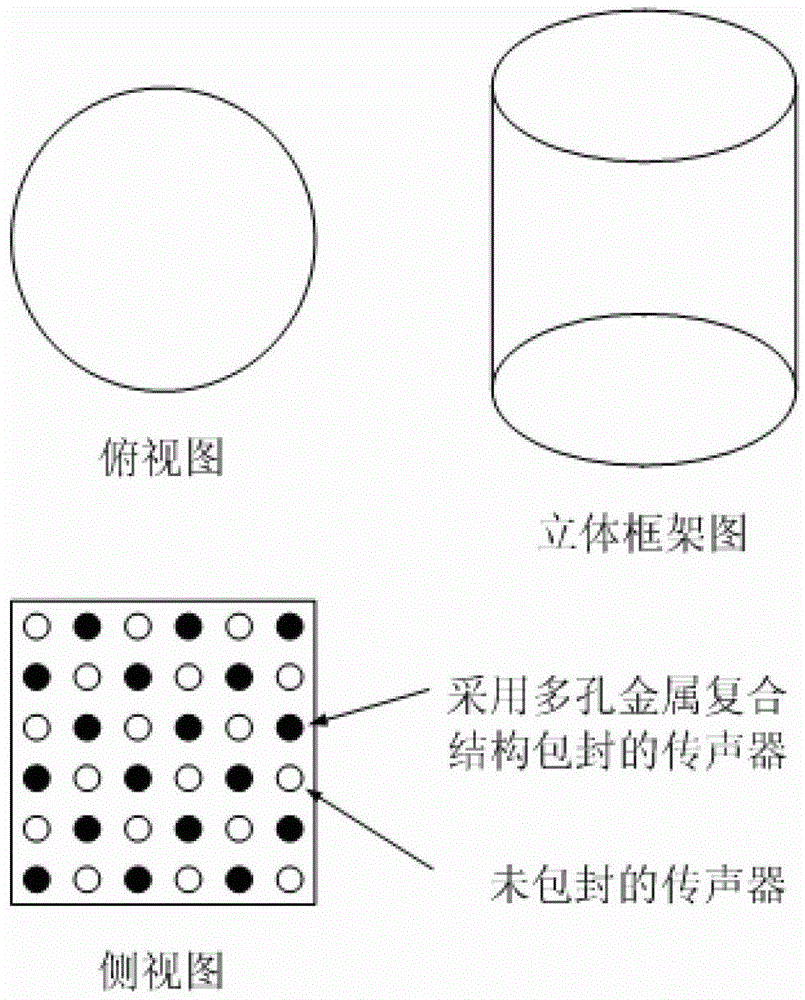

[0018] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 . Specific steps are as follows:

[0019] (1) Divide 16 FiberHome BM-W-2 microphones of the same model (sensitivity -42dB, signal-to-noise ratio 85dB, distortion ≥ 0.3%, maximum sound pressure 120dB, dynamic range 85dB, measurement response frequency 100Hz~18KHz) into two groups , the sound inlet corresponding to the electret of a group of microphones is encapsulated with a porous metal composite structure (the specific structure is shown in the attached figure 2 shown) for high-frequency filtering, and the sound inlet corresponding to the electret of the other group of microphones is directly connected to the external environment. belong to the same group (for the three-dimensional arrangement diagram of the microphone, refer to the attached image 3 As shown, the side view of the specific arrangement of 16 microphones is shown in the appendix Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com