Internal force measuring sensor

A technology for measuring sensors and internal forces, applied in the direction of measuring force components, etc., can solve problems such as inability to guarantee the consistency between theoretical analysis and test objects, and achieve the effects of clear force principles, clear force transmission paths, and reliable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

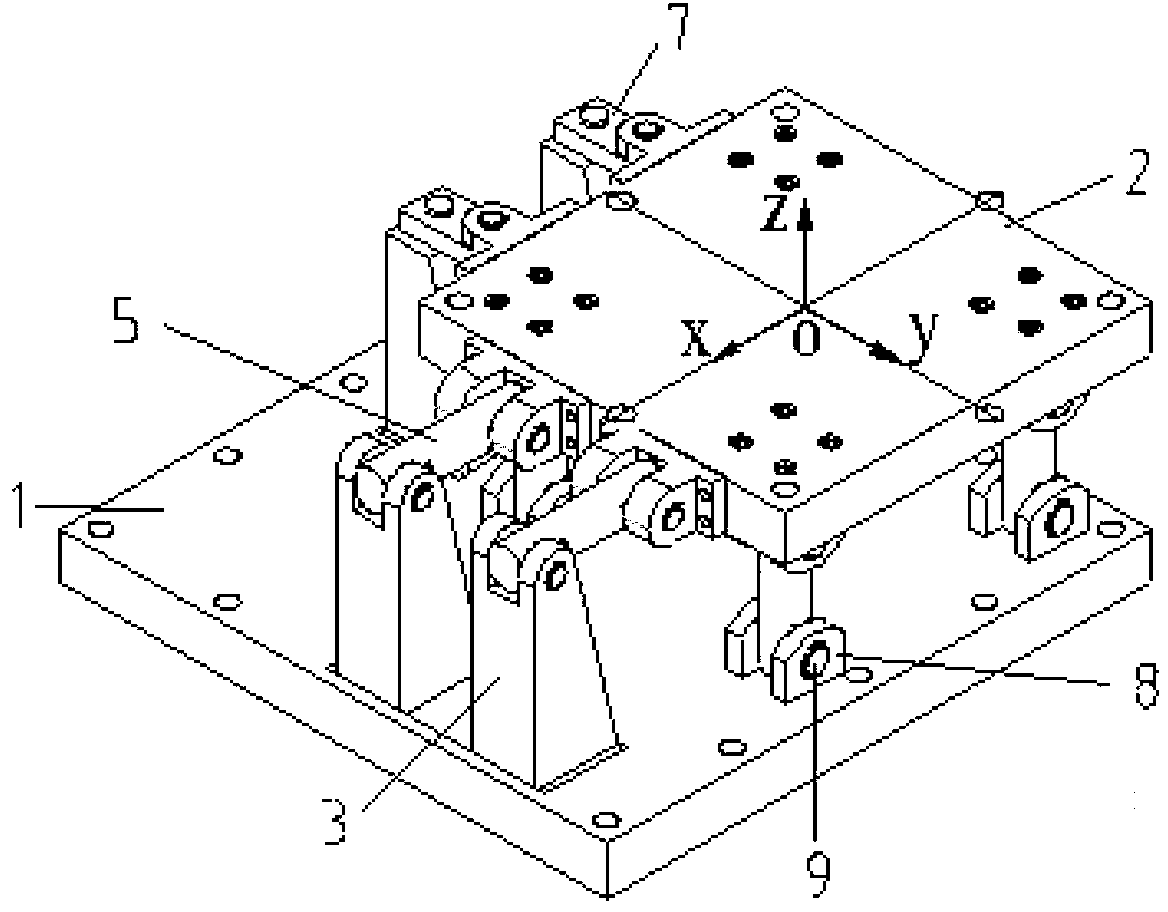

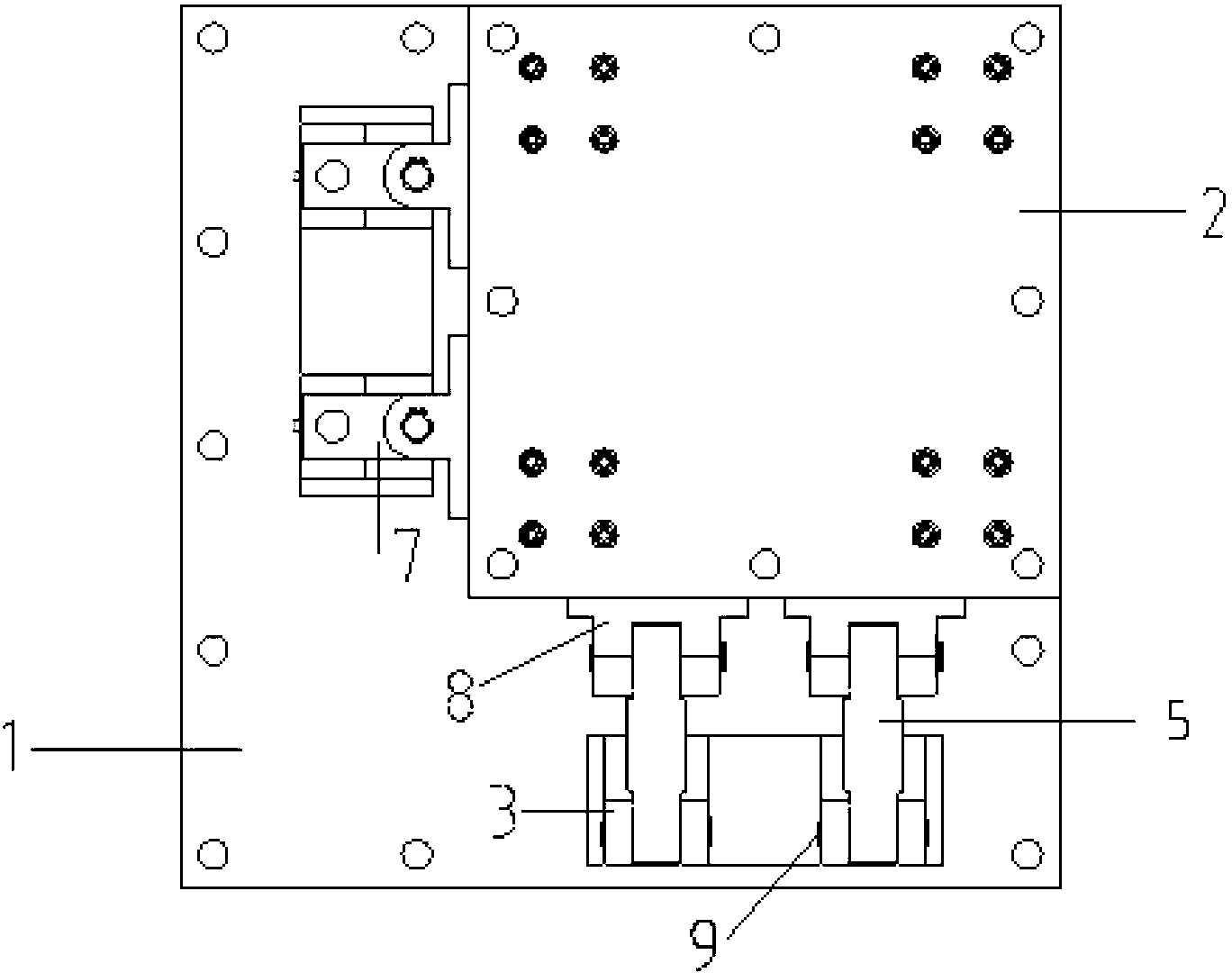

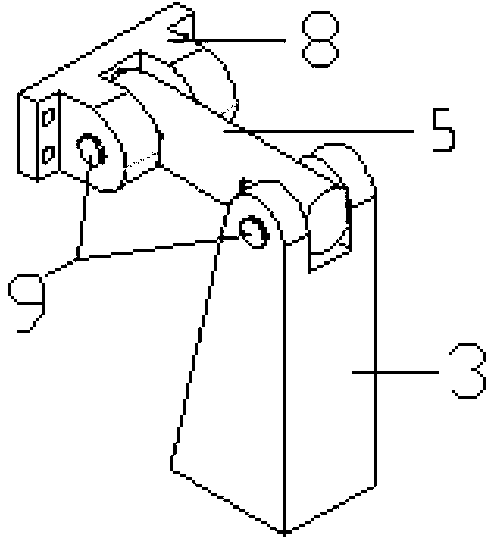

[0043] Such as figure 1 and figure 2 As shown, a kind of internal force measurement sensor, with the center of the installation platen 2 as the origin o, set the x, y, z axes, including the base 1, the installation platen 2, two sets of plane force measuring structures, one set of vertical The force measuring structure and several connectors 8, the mounting plate 2 is located above the base 1, the area of the mounting plate 2 is smaller than the area of the base 1, and the base 1 and the mounting plate 2 are provided with connection holes for connecting the measured equipment , one set of planar force-measuring structures is located on either side of the base perpendicular to the xoz plane, the other set of planar force-measuring structures is located on either side of the base perpendicular to the yoz plane, two sets of planes One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com