Method for evaluating effective porosity of metal corrosion product film

A corrosion product and effective pore technology, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, and measurement devices, can solve problems such as the inability to scientifically evaluate corrosion product film protection, and achieve accurate and scientific protection. , low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

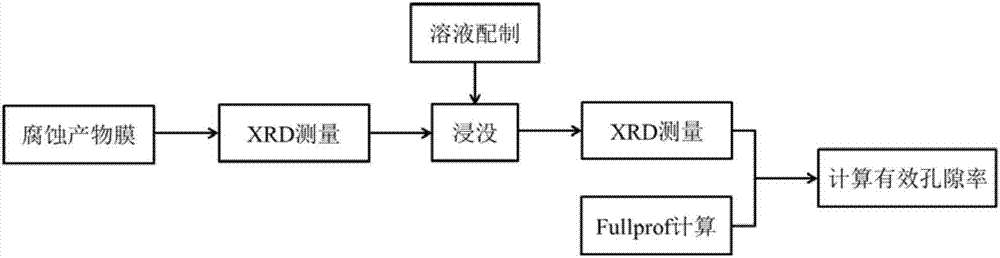

Method used

Image

Examples

Embodiment 1

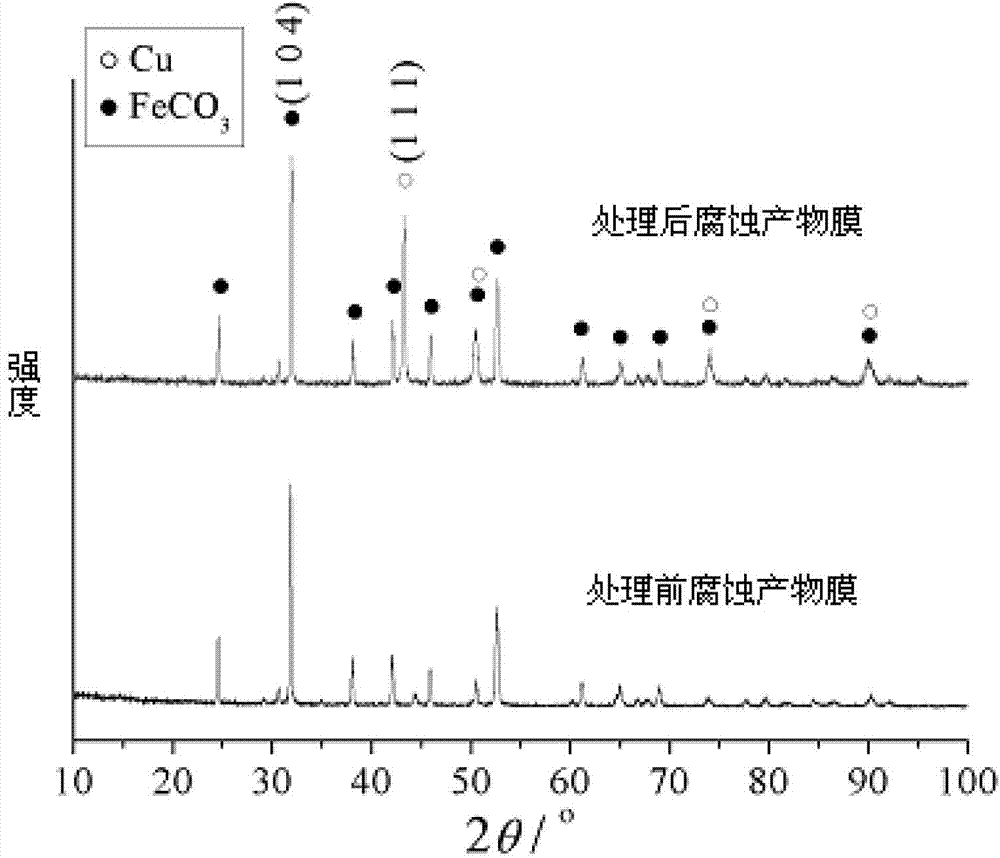

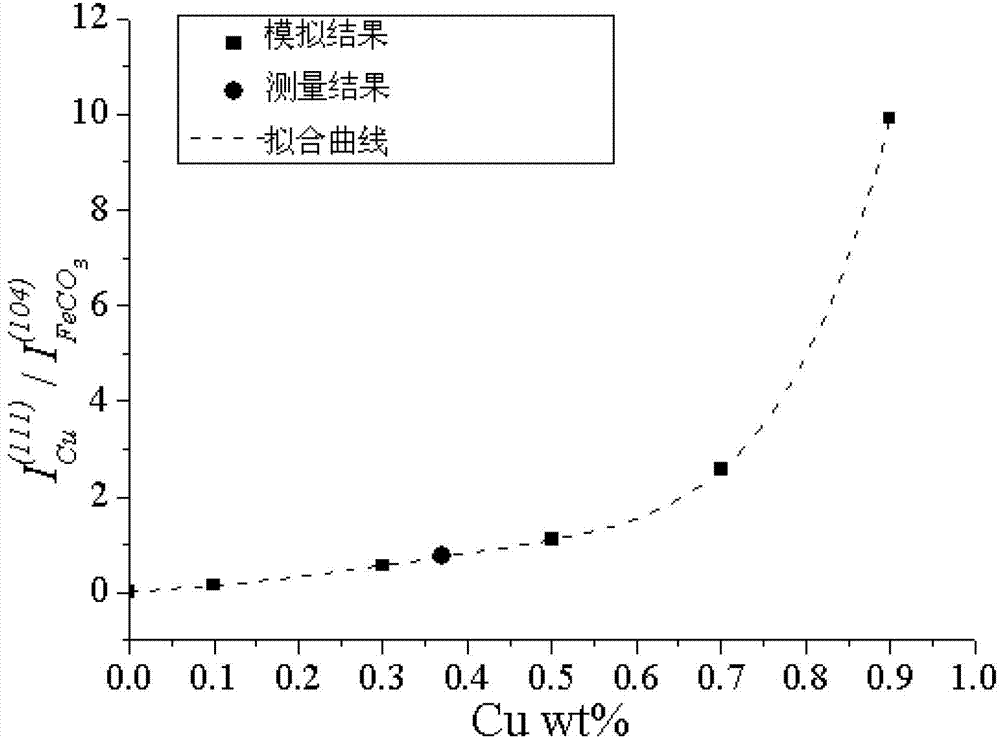

[0037] In this example, a typical steel CO 2 The corrosion product film is used as an example to illustrate this method. The metal matrix of the metal sample is Fe, and the corrosion product in the corrosion product film is FeCO 3 , in order to have a displacement reaction with the metal matrix, a soluble salt solution of metal Cu with a metal activity greater than Fe——CuSO 4 solution as a metal replacement solution.

[0038] Step 1: Obtain a corroded metal sample with a corrosion product film.

[0039] Step 2. Using analytically pure CuSO 4 (5g) and deionized water (95mL) to prepare a copper sulfate solution with a mass fraction of 5% as a metal replacement solution.

[0040] Step 3, immerse the metal sample with the corrosion product film in the 5% copper sulfate solution for 10 minutes, take it out, and use deionized water (or distilled water) and absolute ethanol (analytical grade) to wash successively to obtain A metal sample with a film of corrosion products after tr...

Embodiment 2

[0049] Mg matrix metal CO 2 Taking the corrosion product film as an example, the metal matrix of the metal sample is Mg, and the corrosion product in the corrosion product film is MgCO 3 , the metal replacement solution is AgNO 3 solution.

[0050] Step 1: Obtain a corroded metal sample with a corrosion product film.

[0051] Step 2. Using analytically pure AgNO 3 (6g) and deionized water (94mL) to prepare a silver nitrate solution with a mass fraction of 6% as a metal replacement solution.

[0052] Step 3. Immerse the sample with the corrosion product film in the above 6% silver nitrate solution for 10 minutes, then take it out, and wash it successively with deionized water and absolute ethanol (analytical grade) to obtain the corrosion product with the treated product. Film metal samples.

[0053] Step 4. Carry out XRD phase analysis on the corrosion product film after the treatment, and calculate the replacement metal Ag and the corrosion product MgCO in the corrosion ...

Embodiment 3

[0059] Taking the corrosion product film in the iron matrix metal NaCl aqueous solution as an example, the metal matrix of the metal sample is Fe, the corrosion product in the corrosion product film is γ-FeOOH, and the metal replacement solution is CuCl 2 solution.

[0060] Step 1: Obtain a corroded metal sample with a corrosion product film.

[0061] Step two, using analytically pure CuCl 2 (5g) and deionized water (95mL) to prepare a copper chloride solution with a mass fraction of 5% as a metal replacement solution.

[0062] Step 3. Immerse the sample with the corrosion product film in the above 5% copper chloride solution for 10 minutes, then take out the sample, and clean the corrosion product film with deionized water and absolute ethanol (analytical grade) successively. , to obtain a metal sample with a film of corrosion product after treatment.

[0063] Step 4. Carry out XRD phase analysis on the treated corrosion product film, calculate the highest diffraction peak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com