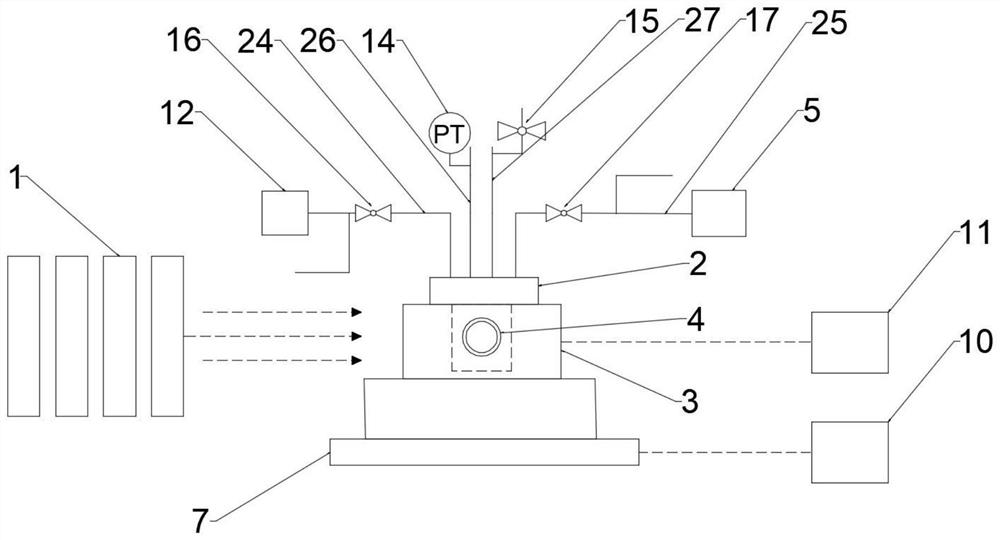

System and method for in-situ spectral measurement of corrosion behavior of reactor cladding material

A cladding material, in-situ spectroscopy technology, applied in the field of chemical analysis equipment, can solve problems such as unattainable, unrealistic conditions, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

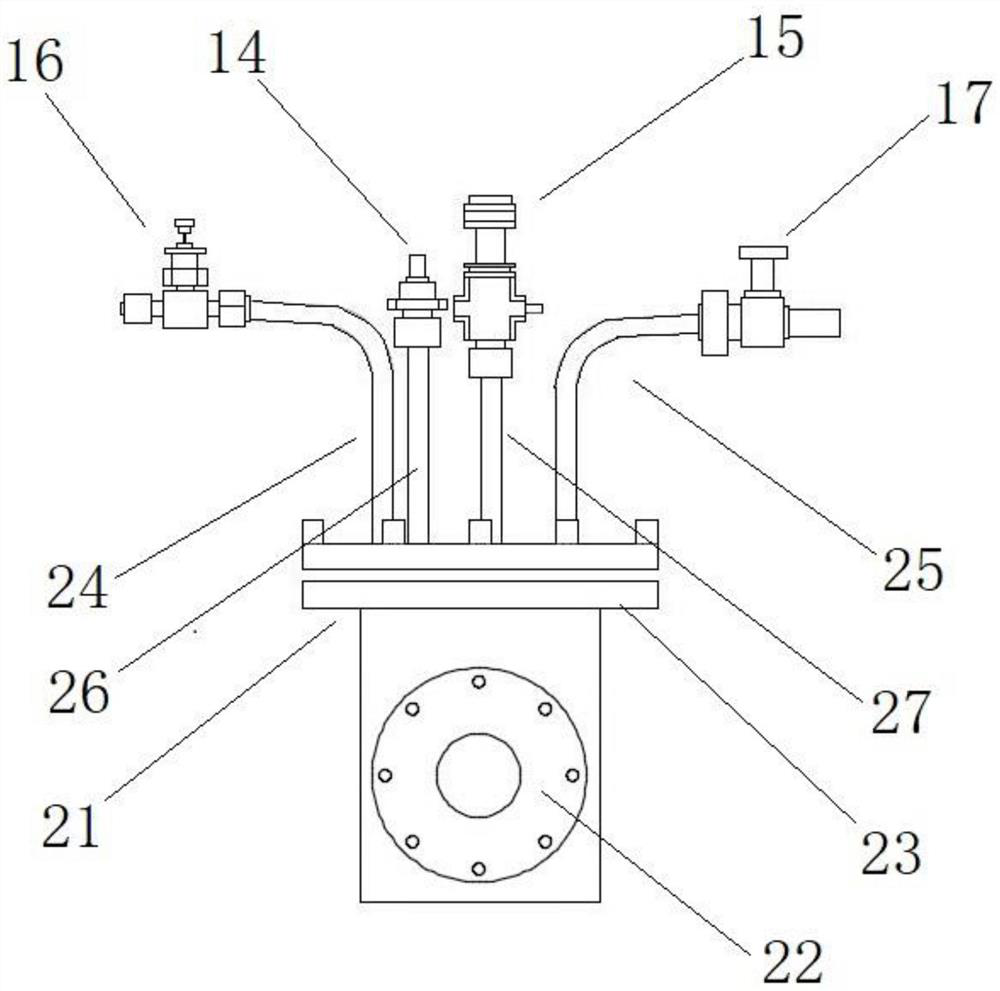

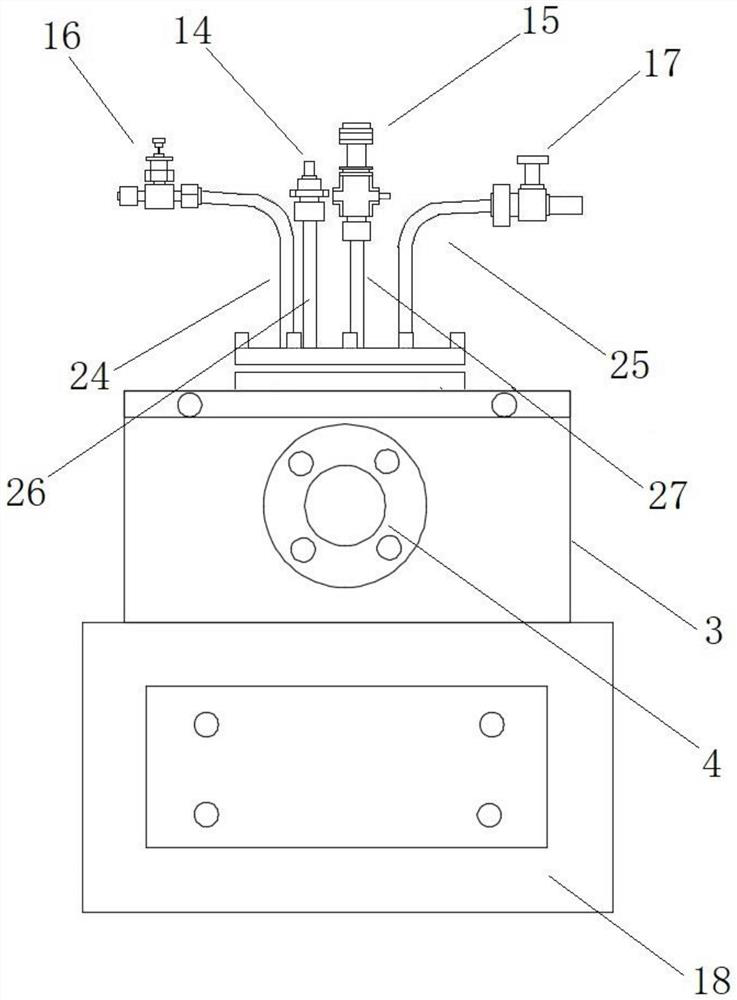

[0065] Measure the infrared spectrum changes of SiC under high temperature radiation conditions;

[0066] 0.6767 g of SiC powders with different particle sizes and 35 ml of deionized water were prepared into a suspension and put into the reaction kettle. After putting stainless steel magnets in the reaction kettle, the sealing cover was sealed and fastened with a wrench. Close the sampling valve, connect the carbon dioxide cylinder tube to the reactor sampling line, so that the pressure in the reactor reaches 1 Mpa, close the sampling valve, place the reactor on the lifting platform, and the irradiation window is perpendicular to the direction of the radioactive source. The irradiated aperture is the smallest, the source of the radioactive source is raised, and the heating is started after the height of the radioactive source is stable; the target temperature is 573.15K, after heating up and stirring for 1 hour, turn off the heating power supply, the pressure reaches 25Mpa, and...

Embodiment 2

[0069] The ultraviolet spectrum of the reactor's charge transfer at the interface;

[0070] Prepare a suspension of 0.06g FeCrAl alloy powder with a particle size of 50 nm and 35 mL of deionized water into the reactor, put a stainless steel magnet in the reactor, and use a wrench to seal and fasten the sealing cover . Close the sampling valve, connect the carbon dioxide cylinder tube to the reactor sampling line, so that the pressure in the reactor reaches 2 Mpa, close the sampling valve, connect the gas chromatograph to the reactor sampling line, and then place the reactor on the lifting platform Above, the irradiation window is perpendicular to the direction of the radioactive source, the irradiation aperture is the smallest, the radioactive source is raised and stirred for 1 hour at the same time, and the irradiation dose is 480 Gy / h. During the irradiation process, the deuterium lamp was used as the light source to inject from the irradiation window, and the reactant was ...

Embodiment 3

[0073] Measuring H of Zr-4 Alloy under High Temperature Radiation Condition 2 Because the reaction of zirconium water will produce hydrogen, it is indirectly proved that the reactor cladding material is corroded by measuring the hydrogen production by gas chromatograph;

[0074] 0.06g of Zr-4 alloy powder with a particle size of 50 nm and 35 mL of deionized water were prepared into a suspension and put into the reaction kettle, and a stainless steel magnet was placed in the reaction kettle, and the sealing cover was sealed with a wrench fasten. Close the sampling valve, connect the carbon dioxide cylinder tube to the reactor sampling line, so that the pressure in the reactor reaches 2 Mpa, close the sampling valve, connect the gas chromatograph to the reactor sampling line, and then place the reactor on the lifting platform above, the irradiation window is perpendicular to the direction of the radioactive source, the irradiation aperture is the smallest, the radioactive sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com