Manufacturing method of black insulating film frame of OGS (one glass solution) touch screen

A technology of insulating film and manufacturing method, which is applied in the input/output process of data processing, instruments, electrical digital data processing, etc. It can solve the problems of high temperature resistance, thick black frame BM material, etc., and achieve improved product yield and Production efficiency, improving product quality, improving product contrast and appearance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

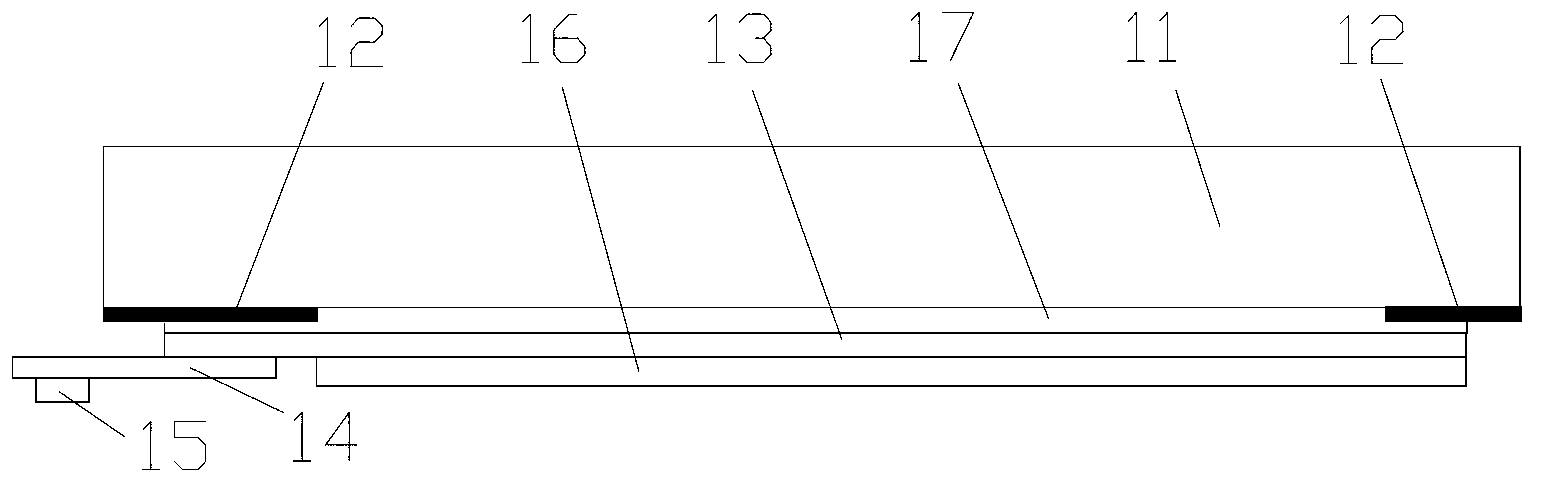

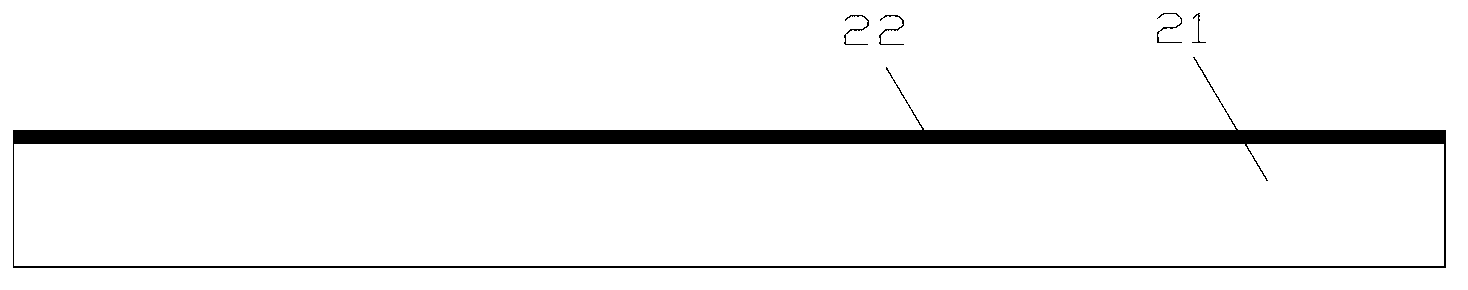

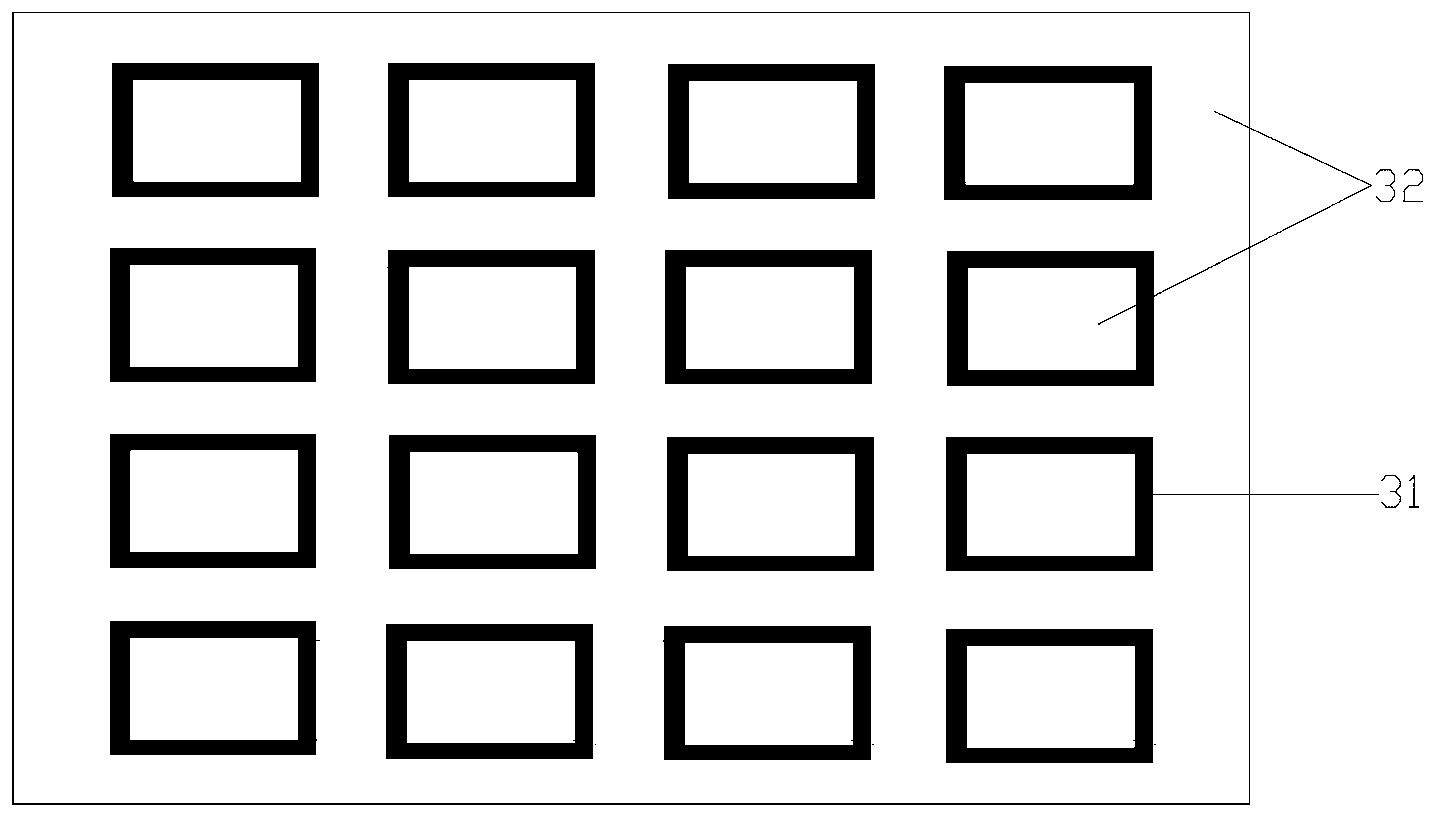

[0029] A manufacturing method of black insulating film frame for OGS touch screen. Stripping technology is used to realize the patterning of black insulating film to form a process scheme of black insulating film frame. The black insulating film can be selected from a variety of materials, preferably black nickel oxide ( The NiO film is a black insulating film, and the specific process includes: cleaning→gluing→exposure→development, hardening→sputtering NiO black insulating film→removal and peeling→inspection; the specific steps are as follows:

[0030] It includes the following steps:

[0031] (1) Cleaning, insert the cover glass into the lye tank made of titanium alloy for ultrasonic lye pre-cleaning, cleaning time: 15-20 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com