Composite helical antenna precision manufacturing method and measurement machining device

A helical antenna and precision manufacturing technology, applied in the field of precision manufacturing method and measurement and processing integrated device of ultra-wideband three-dimensional helical antenna, can solve the problem of inability to solve three-dimensional structure antenna manufacturing, inability to achieve high-precision mass production, and large heat-affected zone. and other problems, to achieve the effect of high degree of automation, good processing flexibility, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

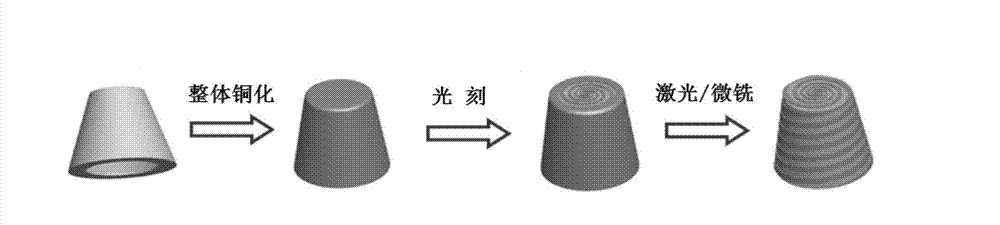

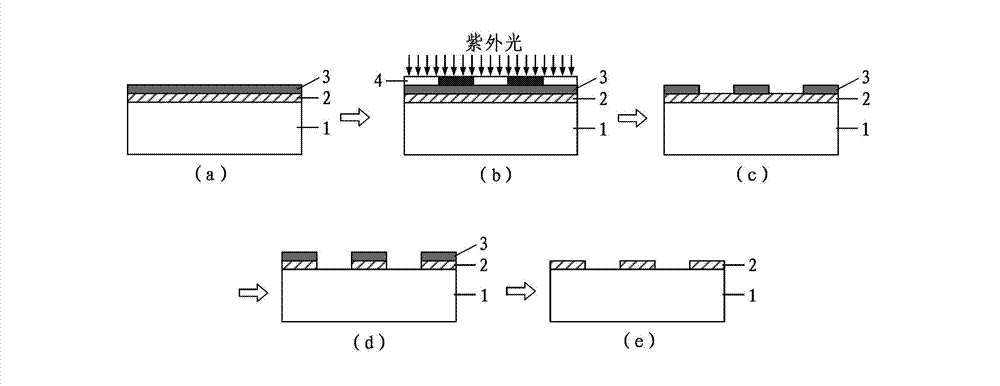

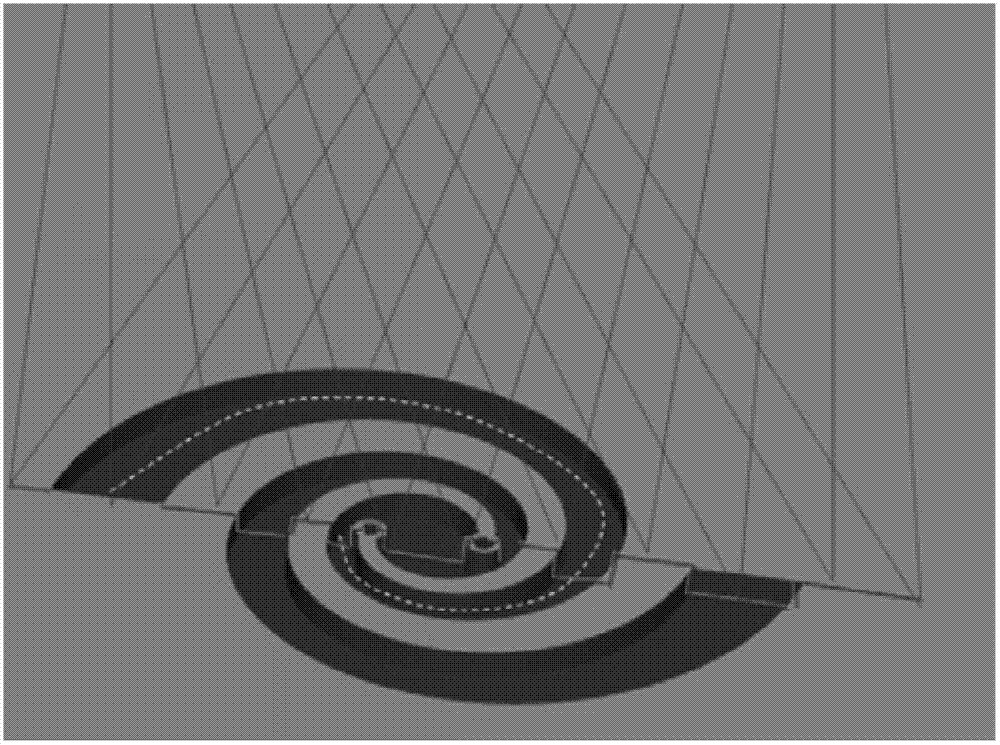

[0022] The specific implementation manner of the present invention is described in detail below in conjunction with accompanying drawing and technical scheme, as appended figure 1 As shown, firstly, the entire surface of the composite helical antenna polyimide substrate 1 is copperized; then, photolithography is performed on the central area of the planar helical antenna; then, laser roughing is performed on the remaining positions except the central area; finally, the The remaining positions outside the central area are finished by CNC micro milling. At the junction of the processing steps, it is also necessary to use high-precision 2D displacement sensors for positioning and compensation. The specific processing flow of the high-precision composite helical antenna is described in detail below:

[0023] (1) Overall copperization of the polyimide substrate surface of the composite helical antenna

[0024] The overall copperization technology on the surface of polyimide sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com