Syringe-microinjection-type infusion device based on shape memory alloy driven and method thereof

A technology of micro-injection and memory alloy, applied in flow monitors, devices introduced into the body, etc., can solve problems such as high cost, complex system, and unstable system, and achieve energy saving, small size, and high energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

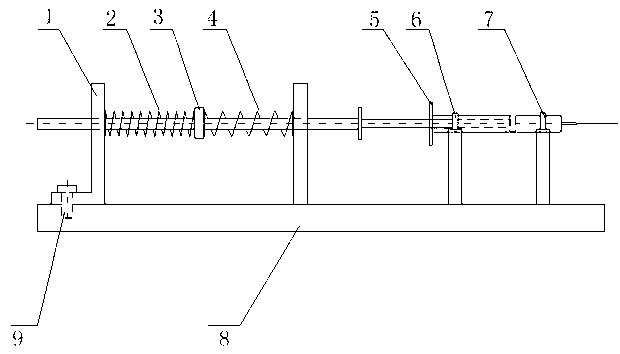

[0020] The working process of the syringe micro-injection infusion device driven by the shape memory alloy spring will be described in detail below with reference to the accompanying drawings.

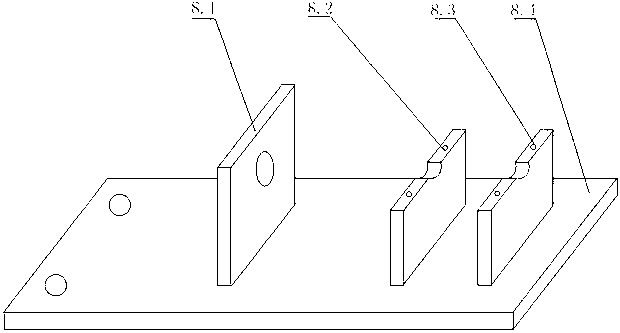

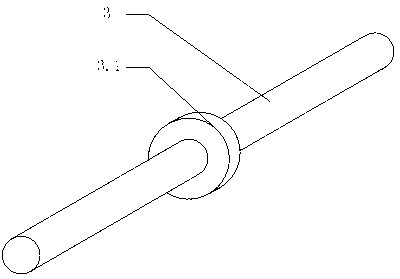

[0021] Such as Figure 1~4 As shown, the syringe microinjection infusion device driven by shape memory alloy includes a support plate 1, a shape memory alloy spring 2, a push rod 3, a return spring 4, a disposable syringe 5, a first clamp 6, a second clamp 7 and Base 8; Base 8 includes baffle plate 8.1, first fixed plate 8.2, second fixed plate 8.3, base plate 8.4; base plate 8.4 is provided with baffle plate 8.1, first fixed plate 8.2 and second fixed plate 8.3, support plate 1 and the baffle plate 8.1 are provided with positioning holes, the first fixed plate 8.2 and the second fixed plate 8.3 are provided with a semicircular fixed groove, the middle of the push rod 3 is provided with a stopper 3.1, and both sides of the stopper 3.1 are provided with shape The memory alloy spring 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Spring rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com