opaque multilayer container

A container and transparent technology, applied in the field of opaque multi-layer containers, can solve the problems of complex formulations, unbalanced follow-up procedures of blow-molded containers, and reduced production performance of preform forming systems, achieving high radiation shielding performance and simplifying the cost of industrial solutions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

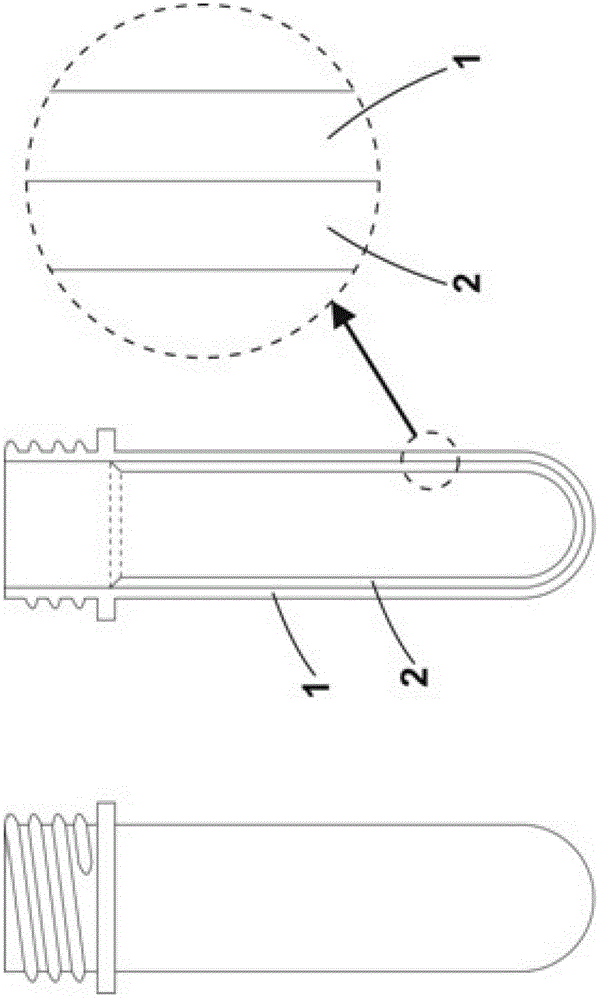

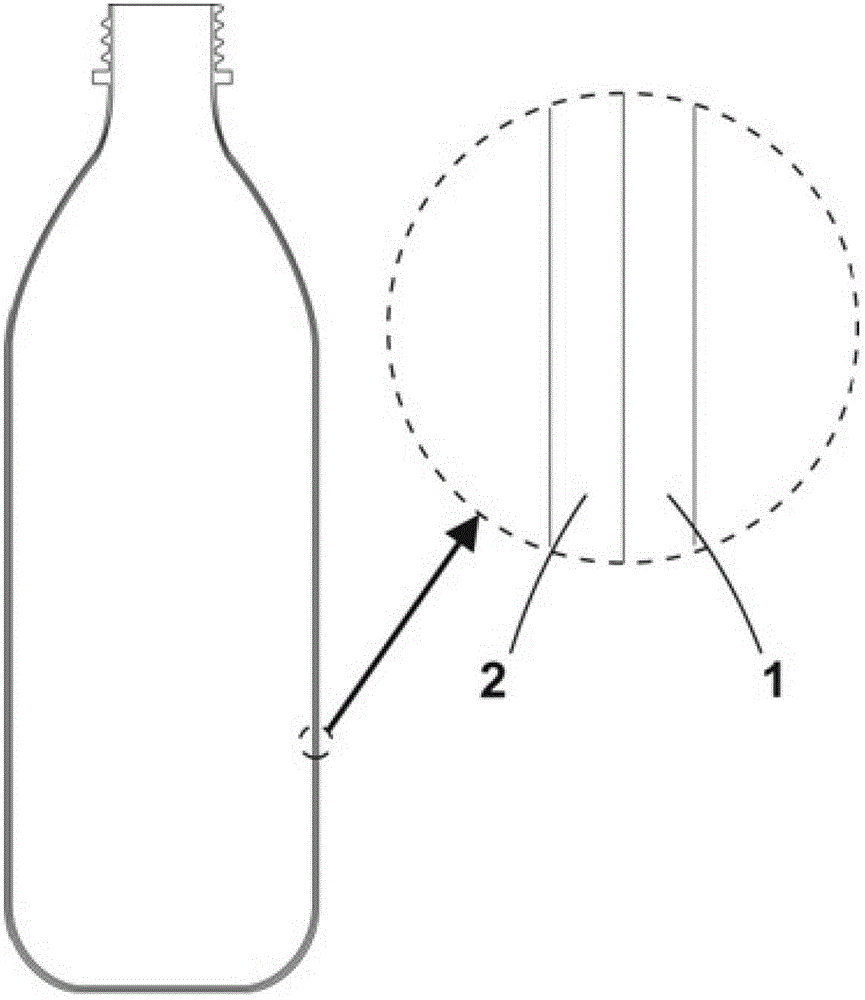

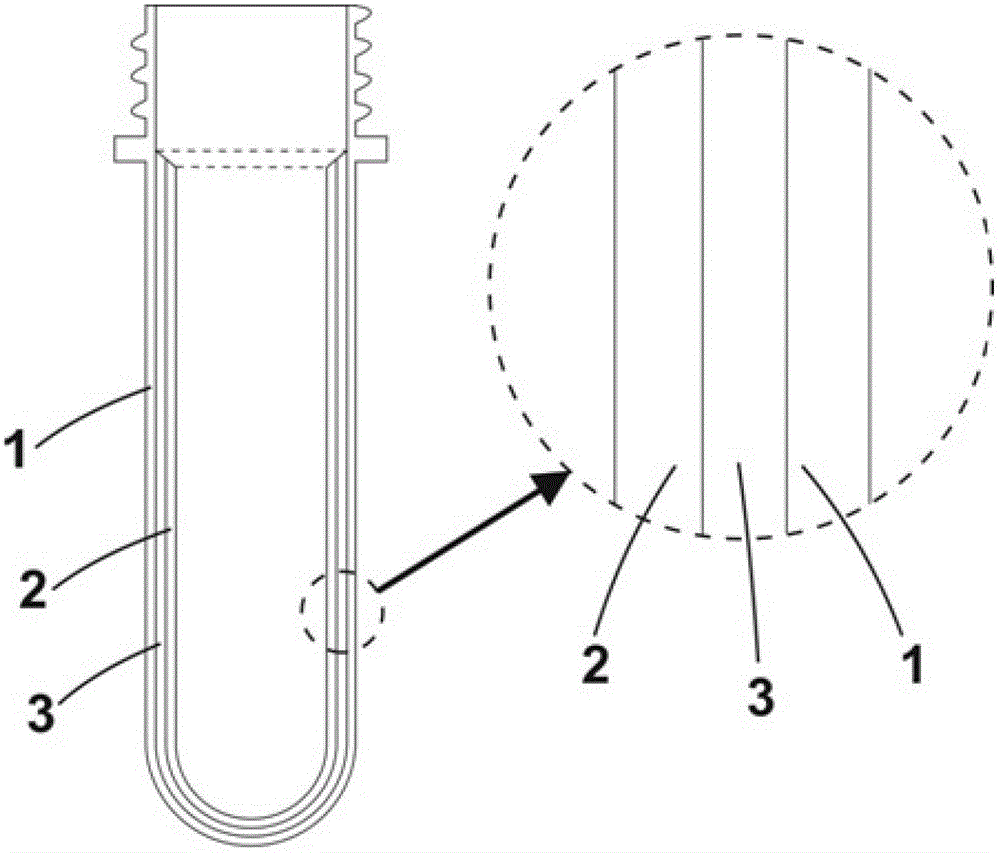

[0072] In order to provide a better understanding of the purpose of the present invention, further description will be made with reference to the accompanying drawings and preferred practical embodiments.

[0073] The object of the invention is an opaque multilayer container, produced by blow molding a preform or by injection blow molding, which essentially comprises at least two layers of thermoplastic material, the opaque material interspersed in the layers of thermoplastic material. The thermoplastic material is polyethylene terephthalate (PET) in all layers, and the opaque material in at least one layer includes metallic aluminum (Al) and a light absorber dispersed in a thermoplastic matrix.

[0074] The light absorbing material is preferably selected from lamp black, activated carbon or iron oxide.

[0075] The metallic aluminium Al is present in a proportion between 0.5% and 2.0%, ie the weight of Al compared to the total weight of each layer comprising Al.

[0076] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com