Rectification dehydration tower and dehydration method for nitrogen dioxide

A technology of nitrogen dioxide and dehydration tower, which is applied in the direction of nitrogen dioxide, nitrogen oxide/oxyacid, liquefaction, etc., and can solve the problem that the top product cannot meet the established requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

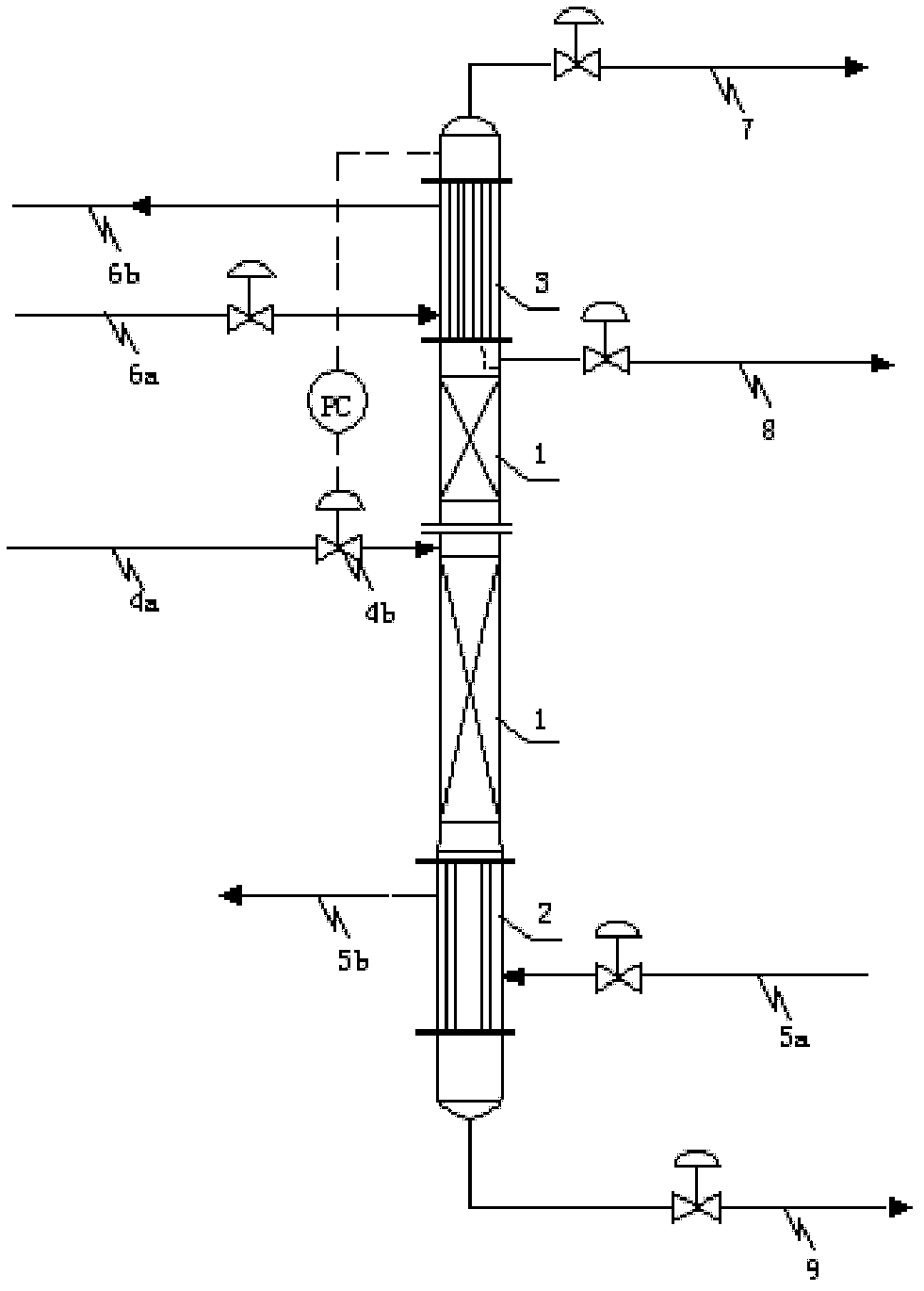

[0054] Such as figure 1 As shown, a nitrogen dioxide rectification dehydration tower is provided with a condensation section 3, a rectification section 1 and a reboiler section 2 from top to bottom in the rectification dehydration tower, and the reboiler section 2 is provided with a heat medium introduction pipe 5a and heat medium outlet pipe 5b; the condensation section 3 is provided with a cold medium introduction pipe 6a and a cold medium outlet pipe 6b; the middle part of the dehydration distillation tower is provided with a nitrogen dioxide feed pipe 4a. The nitrogen dioxide feed pipeline is provided with a regulating valve 4b.

[0055] The nitrogen dioxide raw material enters the rectification and dehydration tower for rectification.

[0056] The gas pressure at the top of the rectification dehydration tower is controlled by adjusting the feed flow rate, and the pressure adjustment setting value is 0.23MPaG.

[0057] Dehydration tower feed: phase state (two-phase flow)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com